Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Template Fitter position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

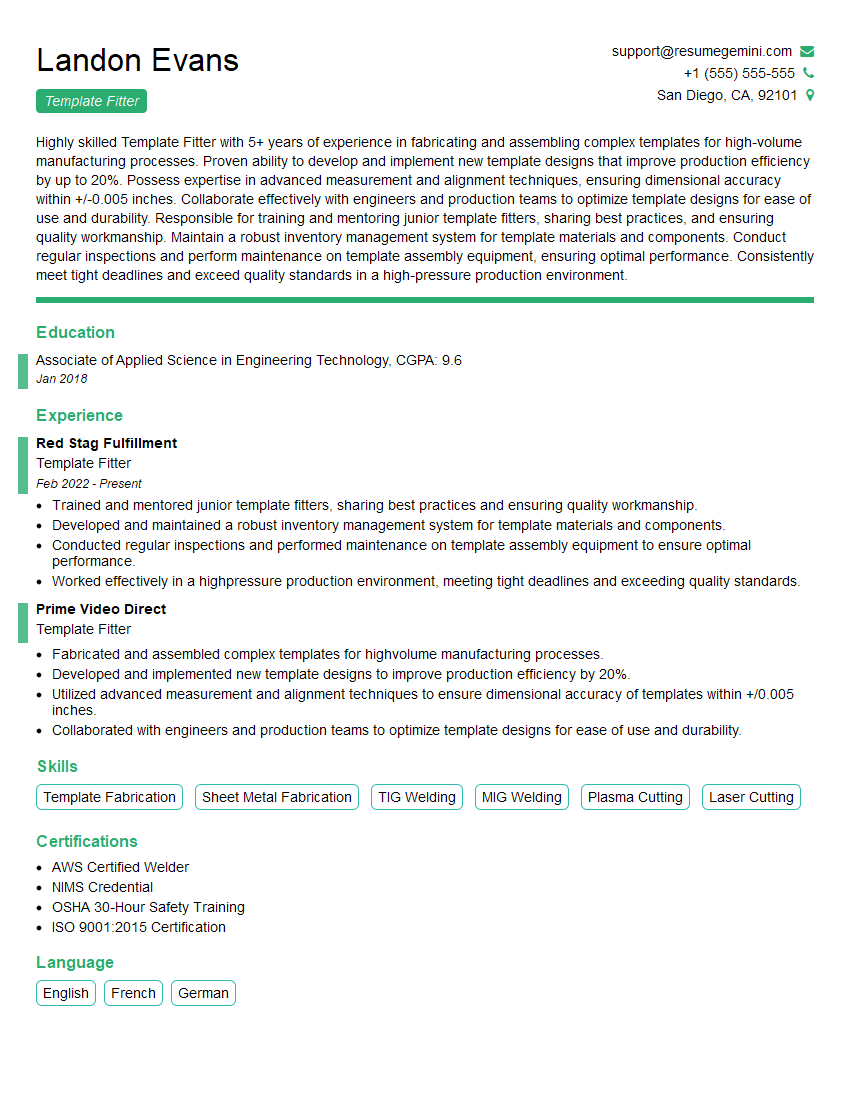

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Template Fitter

1. What are the different types of templates used in sheet metal work?

There are several types of templates used in sheet metal work, including:

- Flat templates: These are the most common type of template and are made from flat sheet metal. They are used to create simple shapes, such as rectangles, circles, and triangles.

- Formed templates: These templates are made from sheet metal that has been bent or formed to create a specific shape. They are used to create more complex shapes, such as cylinders, cones, and spheres.

- Combination templates: These templates are a combination of flat and formed templates and are used to create complex shapes that require both flat and formed sections.

2. What are the steps involved in creating a template?

Materials and Equipments

- Gather the necessary materials, including sheet metal, a template layout, and a template cutter.

- Transfer the template layout to the sheet metal.

Creating the Template

- Cut out the template using the template cutter.

- Check the template for accuracy and make any necessary adjustments.

3. How do you use a template to cut sheet metal?

To use a template to cut sheet metal, you will need to:

- Secure the template to the sheet metal.

- Use a cutting tool, such as a plasma cutter or a shear, to cut along the edge of the template.

- Remove the template and check the cut for accuracy.

4. What are some of the challenges of template fitting?

Some of the challenges of template fitting include:

- Accuracy: Templates must be accurate in order to produce accurate cuts. This can be difficult to achieve, especially when working with complex shapes.

- Material thickness: The thickness of the sheet metal can affect the accuracy of the cut. Thicker sheet metal can be more difficult to cut accurately.

- Equipment: The type of cutting equipment used can also affect the accuracy of the cut. Plasma cutters and shears are two of the most common types of cutting equipment used for template fitting.

5. How do you ensure that a template is accurate?

To ensure that a template is accurate, you can:

- Use a precise measuring tool to transfer the template layout to the sheet metal.

- Check the template for accuracy before cutting.

- Use a sharp cutting tool to cut along the edge of the template.

- Check the cut for accuracy.

6. What are some of the safety precautions that you should take when using templates?

Some of the safety precautions that you should take when using templates include:

- Wear appropriate safety gear, such as gloves and safety glasses.

- Use a sharp cutting tool.

- Be aware of your surroundings and keep your hands away from the cutting area.

- Do not use templates that are damaged or worn.

7. What are some of the different applications of templates in sheet metal work?

Templates are used in a variety of applications in sheet metal work, including:

- Creating custom shapes: Templates can be used to create custom shapes that would be difficult or impossible to cut by hand.

- Reproducing shapes: Templates can be used to reproduce shapes that are needed multiple times.

- Creating complex assemblies: Templates can be used to create complex assemblies that would be difficult or impossible to assemble without a template.

8. What are some of the advantages of using templates in sheet metal work?

Some of the advantages of using templates in sheet metal work include:

- Accuracy: Templates can help to ensure that cuts are accurate and precise, reducing scrap and rework.

- Efficiency: Templates can help to speed up the cutting process, saving time and money.

- Consistency: Templates can help to ensure that multiple parts are cut to the same specifications, resulting in a consistent product.

9. What are some of the disadvantages of using templates in sheet metal work?

Some of the disadvantages of using templates in sheet metal work include:

- Cost: Templates can be expensive to purchase or create.

- Storage: Templates can be bulky and require a lot of storage space.

- Maintenance: Templates can become damaged or worn over time and require maintenance or replacement.

10. What are some of the trends in template fitting?

Some of the trends in template fitting include:

- The use of computer-aided design (CAD) software: CAD software can be used to create templates that are accurate and precise, reducing the risk of errors.

- The use of laser cutting machines: Laser cutting machines can be used to cut templates with a high degree of accuracy and precision.

- The use of 3D printing: 3D printing can be used to create templates that are complex and would be difficult or impossible to create using traditional methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Template Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Template Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Template Fitters are skilled professionals responsible for installing and maintaining templates used in the automotive, aerospace, and other industries.

1. Template Analysis and Interpretation

Analyze and interpret blueprints, drawings, and specifications to determine the proper layout, fit, and functionality of templates.

2. Template Fabrication and Assembly

Fabricate and assemble templates using a variety of materials and techniques, such as metalworking, welding, and precision machining.

3. Template Installation and Alignment

Install and align templates on parts and assemblies using precision tools and equipment to ensure proper fit and dimensional accuracy.

4. Template Maintenance and Repair

Maintain and repair templates to keep them in good working order, including replacing worn or damaged components and performing periodic inspections.

5. Coordinate with Other Departments

Coordinate with engineering, production, and quality control departments to ensure the proper use and maintenance of templates.

Interview Tips

To ace the interview for a Template Fitter position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company and the specific Template Fitter position to understand their industry, products, and the role’s responsibilities.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in template fabrication, installation, and maintenance. Quantify your experience with examples of projects or tasks you have successfully completed.

3. Showcase Problem-Solving Abilities

Template Fitters often encounter challenges during installation or maintenance. Be prepared to share examples of how you solved technical problems and ensured the accuracy and functionality of your work.

4. Highlight Attention to Detail

Precision is paramount in template fitting. Highlight your strong attention to detail and ability to work with precision tools and equipment.

5. Practice Common Interview Questions

Prepare for common interview questions related to your skills, experience, and approach to problem-solving. Practice answering these questions in a clear and concise manner to demonstrate your confidence and preparedness.

6. Dress Professionally and Be Punctual

Make a good impression by dressing professionally and arriving for the interview on time. Show respect for the interviewer’s time and schedule.

7. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the company and the role. This also gives you an opportunity to clarify any uncertainties or gain further insights into the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Template Fitter interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!