Feeling lost in a sea of interview questions? Landed that dream interview for Tenon Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tenon Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

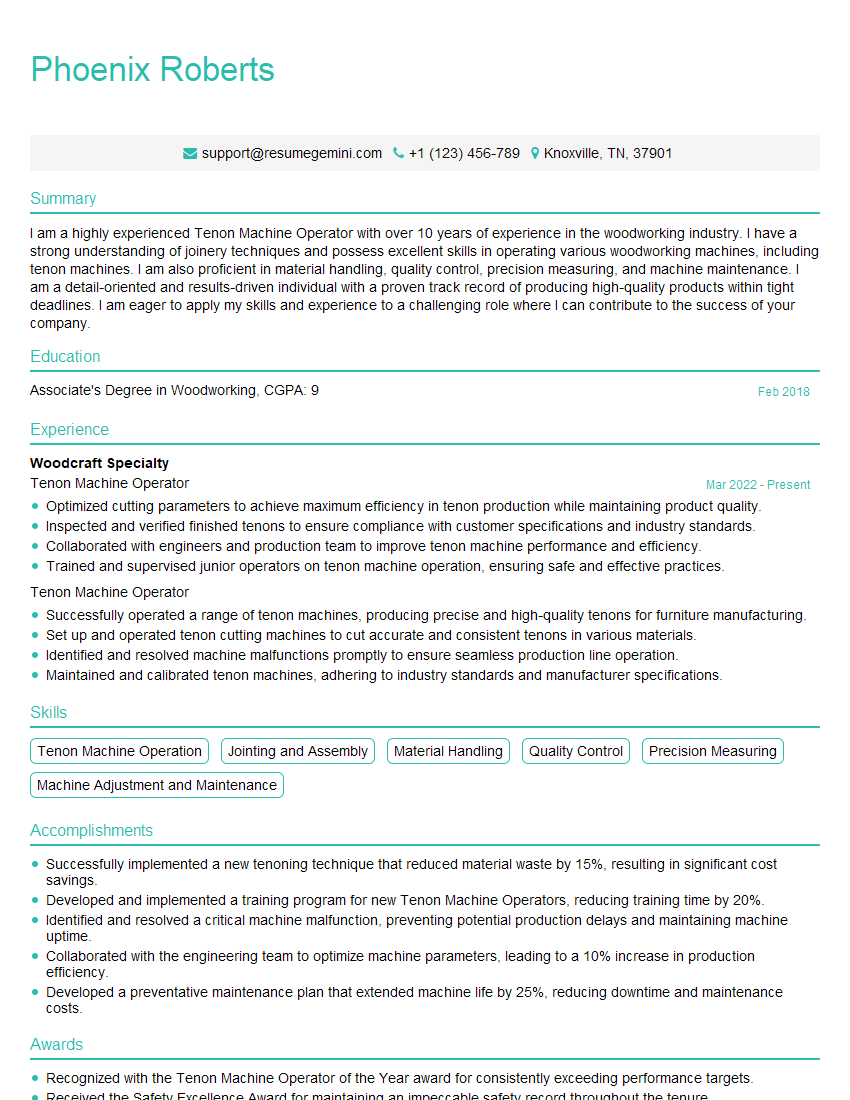

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tenon Machine Operator

1. What are the different types of tenon machines, and what is their primary purpose?

- Double-end tenoners create tenons on both ends of a workpiece simultaneously, commonly used in furniture and door manufacturing.

- Single-end tenoners create tenons on one end of a workpiece, often used in smaller workshops or for custom projects.

- Copying tenoners use a template to create identical tenons, ensuring precision and consistency, especially in high-volume production.

2. Describe the process of setting up a tenon machine, including the factors that need to be considered.

Factors to Consider:

- Type and size of tenon required

- Material being used

- Speed and feed settings

- Tool sharpness and condition

Setup Process:

- Mount and align the appropriate cutter heads

- Adjust the table height and fence position

- Set the speed and feed rates

- Test the setup on scrap material before proceeding

3. What are the common troubleshooting techniques for tenon machines, and how do you diagnose and resolve them?

- Rough or uneven tenons: Check cutter sharpness, adjust speed and feed rates, and inspect for workpiece damage.

- Tenons too small or large: Verify cutter size, adjust cutter head position, and ensure proper material thickness.

- Machine vibrations: Check for loose parts, worn bearings, or unbalanced cutter heads. Ensure proper lubrication and alignment.

4. How do you ensure the accuracy and precision of tenons produced on the machine?

- Regularly calibrate the machine and cutters

- Use sharp and properly maintained cutters

- Set up the machine carefully and accurately

- Check tenon dimensions regularly using measuring tools

- Maintain a clean and organized work area

5. What are the safety precautions that must be followed when operating a tenon machine?

- Wear appropriate safety gear, including safety glasses, gloves, and ear protection

- Never operate the machine with loose clothing or jewelry

- Keep hands and fingers away from cutter heads

- Ensure the workpiece is securely clamped

- Follow manufacturer’s instructions for proper operation and maintenance

6. Describe the importance of maintaining and servicing a tenon machine regularly.

- Extends the machine’s lifespan

- Improves accuracy and precision

- Reduces the risk of breakdowns and accidents

- Maintains optimal performance

- Ensures a safe and efficient work environment

7. What is the difference between a shoulder tenon and a plain tenon, and where are they typically used?

- Shoulder tenon: Has a shoulder or step that prevents it from being inserted too far into a mortise. Commonly used in furniture construction.

- Plain tenon: Does not have a shoulder. Typically used in smaller applications where precise depth is not critical.

8. What are some techniques for increasing the efficiency of a tenon machine operation?

- Optimize cutter speeds and feed rates for the material being used

- Use sharp and properly maintained cutters

- Batch process similar tenon sizes to minimize setup changes

- Automate the process with a conveyor or feeder system

9. How do you handle situations where the tenons produced do not meet the required specifications?

- Identify the source of the problem (e.g., machine setup, material defects, dull cutters)

- Adjust the machine or replace components as necessary

- Recalibrate the machine if needed

- Contact the manufacturer or a qualified technician for assistance if unable to resolve the issue

10. What are the latest advancements or trends in tenon machine technology?

- Computer-controlled machines for increased accuracy and automation

- High-speed cutters for improved efficiency

- Automatic tenon sizing and positioning systems

- Integration with other woodworking machinery for streamlined production

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tenon Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tenon Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tenon Machine Operators play a vital role in the manufacturing process, ensuring the precision and quality of wooden components. Their key responsibilities include:

1. Machine Setup and Operation

Setting up and calibrating tenon machines according to specifications.

- Selecting and installing appropriate cutting tools.

- Adjusting machine settings for speed, feed rate, and depth of cut.

2. Material Handling and Processing

Loading, unloading, and feeding wooden materials into the tenon machine.

- Inspecting materials for defects and ensuring proper dimensions.

- Operating the machine to cut tenons (male projections) and mortises (female recesses).

3. Quality Control

Measuring and inspecting tenons and mortises for accuracy and conformance to specifications.

- Identifying and correcting any deviations from the required dimensions.

- Maintaining records of inspections and reporting any quality issues.

4. Maintenance and Troubleshooting

Performing basic maintenance tasks such as cleaning, lubrication, and minor repairs.

- Monitoring machine performance and identifying potential problems.

- Troubleshooting and resolving operational issues to minimize downtime.

Interview Tips

Preparing for the interview as a Tenon Machine Operator requires a combination of technical knowledge, attention to detail, and a strong work ethic. Here are some tips to help you ace your interview:

1. Research the Company and Role

Take time to research the company you are applying for and the specific responsibilities of the Tenon Machine Operator position. This will demonstrate your interest and enthusiasm for the role.

2. Highlight Relevant Skills and Experience

Emphasize your experience in operating tenon machines, including your understanding of setup, operation, and quality control processes. If you have experience working with specific types of materials or within particular industries, be sure to mention it.

3. Demonstrate Attention to Detail

Tenon Machine Operators must have a keen eye for detail to ensure the precision of their work. In your interview, provide examples of your ability to measure accurately, follow instructions precisely, and detect any imperfections or deviations from specifications.

4. Show Your Commitment to Quality

Discuss your commitment to producing high-quality work and maintaining high standards. Explain how you have implemented quality control measures in previous roles and your approach to ensuring that products meet or exceed customer expectations.

5. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer. This shows that you are engaged and interested in the role. Questions about the company’s quality standards, training opportunities, or the team environment can be beneficial.

Next Step:

Now that you’re armed with the knowledge of Tenon Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tenon Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini