Are you gearing up for a career in Tensile Tester? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tensile Tester and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

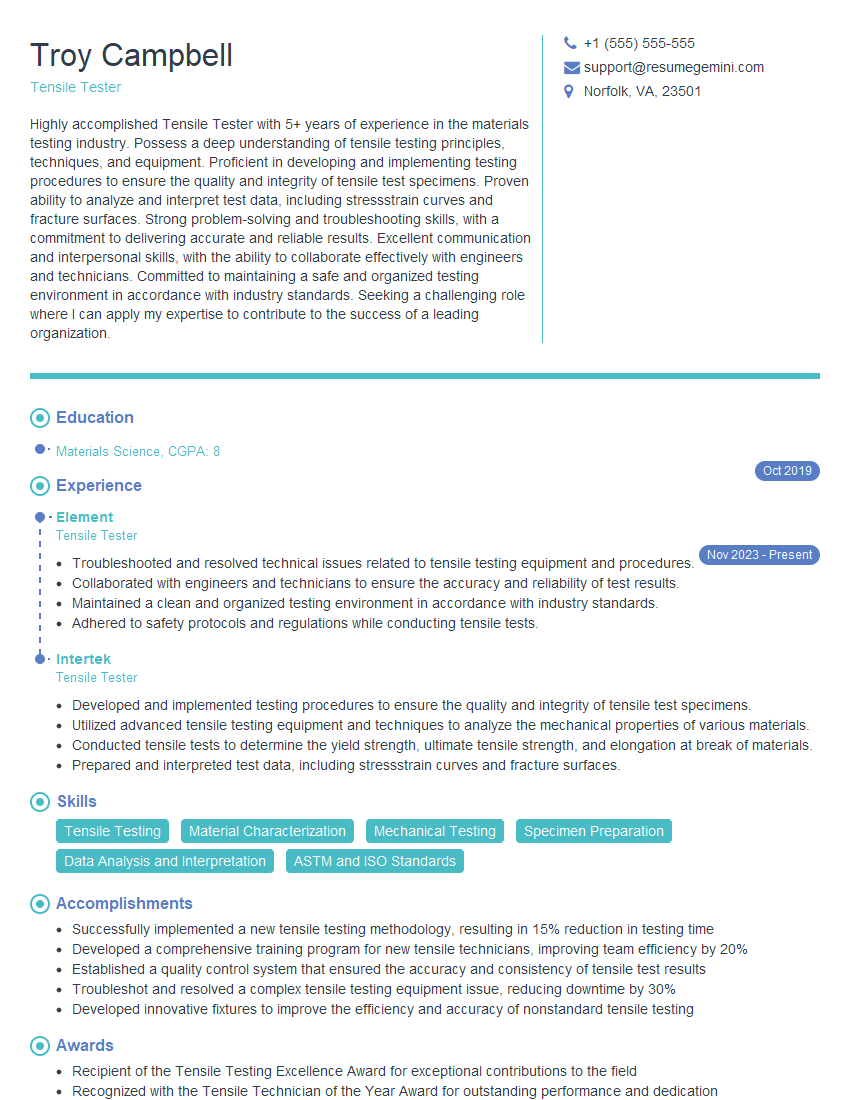

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tensile Tester

1. Explain the principles behind tensile testing?

Tensile testing is a fundamental mechanical test used to determine the behavior of materials under uniaxial tension. It provides valuable insights into a material’s strength, ductility, and elastic properties.

- A specimen of the material is subjected to a controlled tensile force, typically using a testing machine.

- The force is gradually increased while the elongation of the specimen is measured.

- The resulting data is plotted as a stress-strain curve, which provides a graphical representation of the material’s mechanical properties.

2. Describe the different types of tensile testing machines and their applications?

Universal Testing Machines (UTM)

- Versatile machines capable of performing various mechanical tests, including tensile testing.

- Used for a wide range of materials, including metals, plastics, and composites.

Electro-Mechanical Testing Machines

- Powered by electric motors, providing precise control over the applied force.

- Suitable for testing materials with high strength and stiffness.

Hydraulic Testing Machines

- Use hydraulic pressure to apply the tensile force.

- Ideal for testing materials with large cross-sectional areas or requiring very high forces.

3. What are the critical parameters measured during a tensile test?

- Stress: Force applied per unit area of the specimen’s original cross-section.

- Strain: Elongation of the specimen divided by its original length.

- Young’s modulus: Slope of the linear portion of the stress-strain curve, representing the material’s stiffness.

- Yield strength: Stress at which the material begins to deform plastically.

- Ultimate tensile strength: Maximum stress that the material can withstand before failure.

4. How do you interpret the results of a tensile test?

The stress-strain curve provides valuable information about the material’s behavior under tension. By analyzing the curve, we can determine:

- Elasticity and stiffness

- Yielding and plastic deformation

- Ultimate strength and failure mode

- Ductility and toughness

5. What factors can affect the results of a tensile test?

- Specimen preparation: Proper specimen shape, size, and surface finish are crucial.

- Testing conditions: Temperature, humidity, and strain rate can influence the results.

- Equipment calibration: Ensuring accurate measurements from the testing machine is essential.

- Material variability: Natural variations in material properties can lead to slight differences in test results.

6. Describe the different types of extensometers used in tensile testing?

Strain Gauges

- Attached directly to the specimen, measuring strain through electrical resistance changes.

- Suitable for small specimens or precise strain measurements.

Clip-On Extensometers

- Clip onto the specimen’s surface, measuring strain through the movement of two contact points.

- Versatile and easy to use, ideal for various specimen sizes.

Video Extensometers

- Use cameras to track the movement of markers on the specimen’s surface.

- Non-contact measurement, suitable for high-temperature or sensitive materials.

7. Explain how tensile testing can be used in quality control?

Tensile testing plays a vital role in quality control by:

- Verifying the mechanical properties of materials against specifications.

- Identifying defects or inconsistencies in material batches.

- Monitoring changes in material properties over time or under different conditions.

- Ensuring the safety and reliability of products made from the tested materials.

8. Describe the importance of sample preparation in tensile testing?

Proper sample preparation is crucial for accurate and reliable tensile test results. It involves:

- Specimen shape and dimensions: Adhering to standardized specimen geometries to ensure uniform stress distribution.

- Surface finish: Removing surface imperfections or coatings to minimize stress concentrations.

- Alignment: Ensuring the specimen is properly aligned with the testing machine to avoid bending or misalignment.

9. How do you ensure the accuracy and reliability of tensile testing results?

- Equipment calibration: Regularly calibrate the testing machine and extensometers to ensure accurate measurements.

- Proper sample preparation: Follow standardized procedures for specimen preparation to minimize errors.

- Environmental control: Maintain consistent temperature and humidity conditions during testing.

- Data analysis: Use appropriate software and methods for data analysis to extract meaningful information from the test results.

10. What are the latest advancements in tensile testing technology?

- Automated testing systems: Increasing efficiency and reducing human error through automation.

- High-speed tensile testing: Characterizing materials under dynamic loading conditions.

- Digital image correlation (DIC): Non-contact strain measurement using advanced image analysis techniques.

- Multi-axial tensile testing: Evaluating material behavior under combined stress states.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tensile Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tensile Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tensile testers play a crucial role in ensuring the quality and durability of materials used in various industries. Their primary responsibilities include:1. Material Testing and Analysis

Tensile testers conduct tensile tests to determine the mechanical properties of materials, such as tensile strength, yield strength, elongation, and modulus of elasticity.

- Prepare and calibrate testing equipment, including tensile testing machines and extensometers.

- Select appropriate test methods based on industry standards and material specifications.

- Conduct tensile tests and accurately record data.

- Analyze test results to determine the material’s mechanical properties.

2. Quality Control and Assurance

Tensile testers play a vital role in maintaining product quality and ensuring regulatory compliance.

- Develop and implement quality control procedures for tensile testing.

- Monitor tensile test results and identify any deviations from specifications.

- Investigate quality issues and recommend corrective actions.

- Provide technical support to manufacturing and engineering teams.

3. Research and Development

Tensile testers contribute to research and development efforts to improve materials and manufacturing processes.

- Collaborate with scientists and engineers to develop new testing methods and techniques.

- Conduct advanced tensile tests, such as creep and fatigue testing.

- Analyze test results and provide insights that can lead to product innovation.

- Develop and evaluate new materials and manufacturing technologies.

4. Communication and Reporting

Tensile testers must effectively communicate their findings and recommendations to stakeholders.

- Prepare detailed test reports and summarize key results.

- Present technical findings to management and engineering teams.

- Participate in meetings and discussions to provide technical expertise.

- Stay up-to-date on industry best practices and research.

Interview Tips

Preparing thoroughly for an interview for a tensile tester position can significantly increase your chances of success. Here are some valuable tips:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific tensile tester position. Understand their industry, products, and current job openings.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay informed about the latest trends.

- If possible, connect with current or former employees of the company.

2. Highlight Your Technical Skills

Emphasize your technical expertise in tensile testing and related areas. Quantify your accomplishments and provide specific examples of your work.

- Discuss your experience with different tensile testing machines and extensometers.

- Showcase your proficiency in test method development and data analysis.

- Highlight any experience you have with advanced testing techniques, such as creep and fatigue testing.

3. Demonstrate Your Quality-Focused Approach

Tenile testing is critical for maintaining product quality. Highlight your commitment to quality control and assurance.

- Describe your experience in developing and implementing quality control procedures.

- Explain how you have investigated quality issues and recommended corrective actions.

- Share examples of how your work has contributed to improving product quality.

4. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses. Some questions you may encounter include:

- Why are you interested in this position?

- Describe your experience with tensile testing.

- How do you stay up-to-date on industry best practices?

- Can you give an example of a time you resolved a quality issue?

- What are your strengths and weaknesses as a tensile tester?

5. Practice Your Communication Skills

Tensile testers must be able to effectively communicate their findings and recommendations. Practice presenting technical information clearly and concisely.

- Prepare a brief presentation on a recent tensile testing project.

- Ask a friend or family member to provide feedback on your communication skills.

- Attend workshops or webinars on technical communication.

6. Follow Up After the Interview

Send a thank-you note to the interviewer within 24 hours of the interview. Express your appreciation for their time and reiterate your interest in the position.

- Summarize the key points discussed during the interview.

- Reiterate your qualifications and highlight how you can contribute to the company.

- Inquire about the next steps in the hiring process.

Next Step:

Now that you’re armed with the knowledge of Tensile Tester interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tensile Tester positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini