Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Terminal Press Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Terminal Press Operator so you can tailor your answers to impress potential employers.

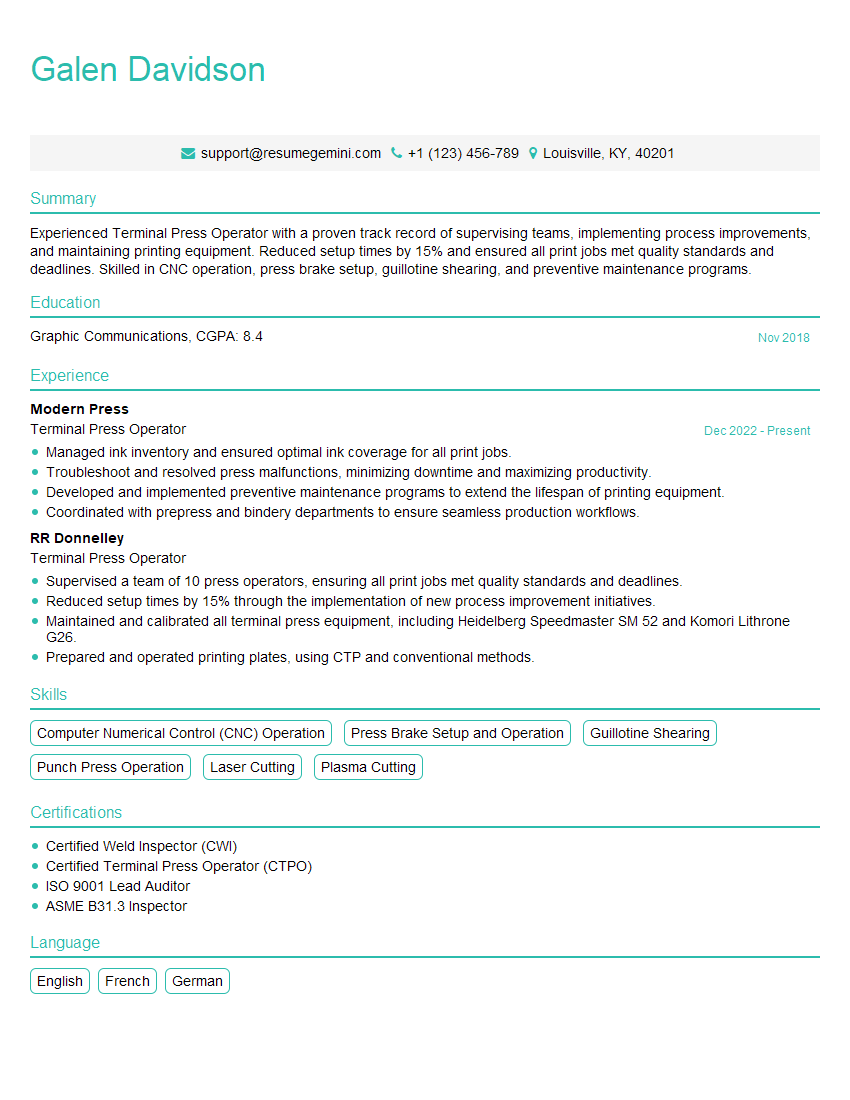

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Terminal Press Operator

1. How to determine paper weight and count on a terminal press?

Determining paper weight and count on a terminal press involves the following steps:

- Calculate the ream weight:

2. Explain the process of setting up a terminal press for a particular job, including platen adjustments and impression settings.

Platen Adjustments

- Adjust the platen height to match the paper thickness

- Set the side and front lays to align the paper correctly

Impression Settings

- Set the impression pressure based on the paper weight and type

- Adjust the dwell time to ensure proper ink transfer

3. What are the different types of terminals, and how do you choose the right one for a job?

Types of terminals include:

- Flatbed terminals: Suitable for general printing tasks

- Rotary terminals: High-speed printing with a cylindrical impression surface

- Gravure terminals: Used for high-quality printing with recessed images

- Flexographic terminals: Ideal for printing on flexible materials

Choosing the right terminal depends on:

- Job requirements (e.g., speed, quality, substrate)

- Available equipment

- Cost and efficiency considerations

4. How do you troubleshoot common problems with a terminal press, such as ink smudging or poor registration?

Ink Smudging

- Check ink viscosity and adjust if necessary

- Inspect rollers for wear or damage

- Ensure proper impression settings

Poor Registration

- Verify that the platen is level

- Adjust the lays to ensure paper alignment

- Inspect the feed system for any issues

5. What safety precautions should be taken when operating a terminal press?

- Wear appropriate safety gear (e.g., gloves, eye protection)

- Keep hands clear of moving parts

- Never attempt to clear jams while the press is running

- Report any malfunctions or potential hazards promptly

- Follow established lockout/tagout procedures

6. How do you ensure consistent print quality on a terminal press?

- Calibrate the press regularly

- Monitor and adjust ink viscosity throughout the run

- Check paper quality and ensure it meets specifications

- Inspect and clean rollers and plates as needed

- Implement quality control measures (e.g., sampling, color matching)

7. How do you handle customer complaints or requests for reprints?

- Listen attentively to the customer’s concerns

- Inspect the printed material to identify the issue

- Communicate clearly with the customer and explain the situation

- Offer solutions or reprints as necessary

- Document the complaint and follow up as needed

8. What are the key maintenance tasks for a terminal press?

- Daily maintenance: Clean rollers, plates, and impression cylinder

- Weekly maintenance: Lubricate moving parts, check fluid levels

- Monthly maintenance: Inspect belts and bearings, clean ink fountain

- Quarterly maintenance: Perform comprehensive inspection and adjustments

- Annual maintenance: Schedule a comprehensive overhaul by a qualified technician

9. How do you stay updated on the latest printing technologies and best practices?

- Attend industry conferences and workshops

- Read trade publications and online resources

- Network with other professionals in the field

- Seek training opportunities from equipment manufacturers

10. What are your expectations for productivity and quality in this role?

- Meet or exceed production targets

- Maintain high print quality standards

- Minimize waste and downtime

- Follow established procedures and safety protocols

- Work effectively as part of a team

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Terminal Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Terminal Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Terminal Press Operators are responsible for operating and maintaining a terminal press machine to produce printed materials in a high-volume production environment. They must ensure that the machine is running smoothly and efficiently, and that all materials are properly fed into the press.

1. Machine Operation

Operate and maintain terminal press machine to create printed materials in a high-volume production environment.

- Set up and adjust the machine according to specifications.

- Monitor the machine during operation and make adjustments as needed.

2. Material Handling

Load and unload paper or other materials into and out of the press.

- Inspect materials for defects before loading them into the press.

- Ensure that all materials are properly fed into the press.

- Remove finished products from the press and inspect them for quality.

3. Quality Control

Inspect printed materials to ensure they meet quality standards.

- Identify and correct any defects in the printed materials.

- Maintain records of all inspection activities.

4. Safety

Follow all safety procedures and regulations when operating the machine.

- Wear appropriate safety gear.

- Keep the work area clean and free of hazards.

- Report any safety concerns to the supervisor.

Interview Tips

Here are some interview tips to help you ace your interview for a Terminal Press Operator position:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, and the specific skills and experience they are looking for in a Terminal Press Operator.

2. Practice answering common interview questions

There are some common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. Take some time to practice answering these questions before your interview.

3. Highlight your skills and experience

In your interview, be sure to highlight your skills and experience that are relevant to the position of Terminal Press Operator. For example, you could talk about your experience operating high-volume printing presses, your knowledge of quality control procedures, or your safety record.

4. Be prepared to talk about your work ethic

Terminal Press Operators are often responsible for working long hours in a fast-paced environment. In your interview, be prepared to talk about your work ethic and how you can handle the demands of the job.

5. Ask questions

At the end of your interview, be sure to ask the interviewer any questions you have. This shows that you are interested in the position and that you are taking the interview seriously.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Terminal Press Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!