Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Test Skein Winder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

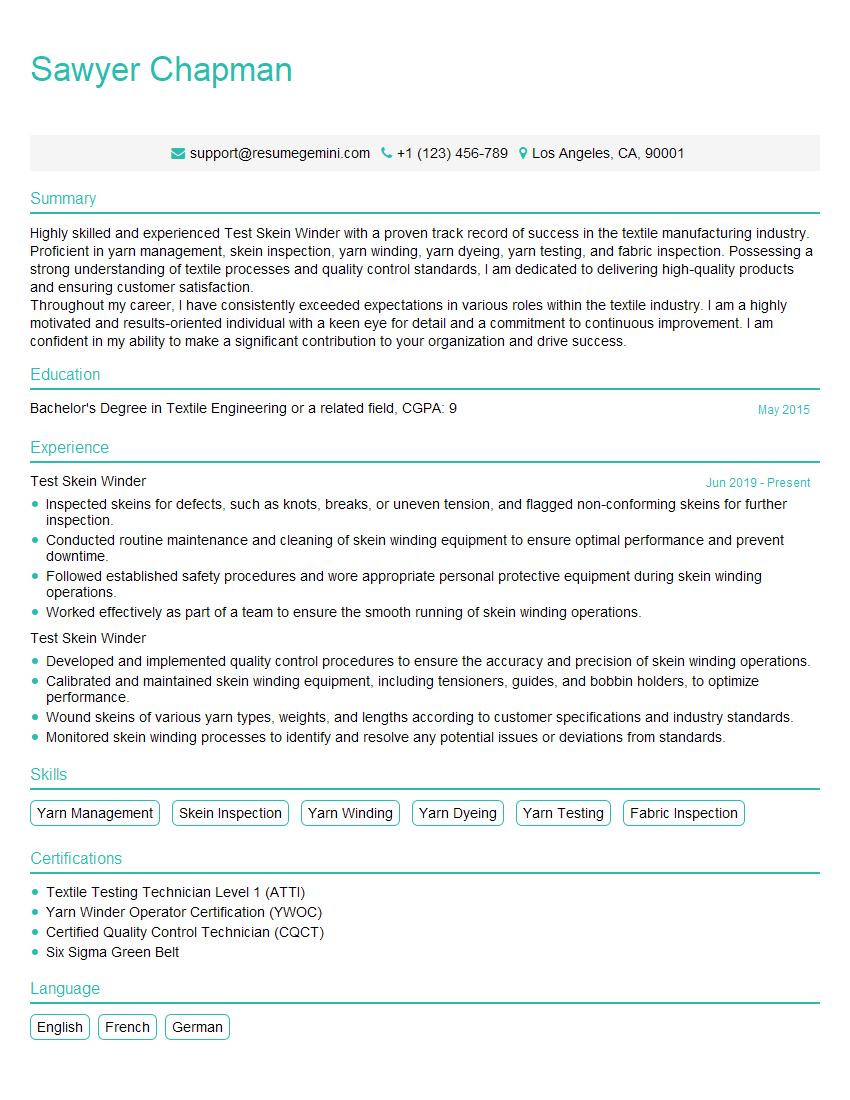

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Test Skein Winder

1. What are the key responsibilities of a Test Skein Winder?

- Operate skein winding machine to wind yarn onto skeins for testing purposes.

- Maintain and calibrate winding machine to ensure accurate and consistent winding.

2. Describe the winding process and the machine used.

Winding process:

- Prepare the yarn by removing any knots or tangles.

- Place the yarn on the winding machine and secure it in place.

- Set the winding speed and tension.

- Start the winding process and monitor the skein as it forms.

Winding machine:

- Consists of a rotating spindle that holds the yarn.

- A traverse mechanism that moves the yarn back and forth across the spindle.

- A tension control system that regulates the tension of the yarn.

3. How do you ensure the quality of the wound skeins?

- Inspect the skeins for any knots, breaks, or uneven winding.

- Measure the length and weight of the skeins to ensure they meet specifications.

- Keep a record of the winding parameters and any deviations from the standard.

4. What are the common problems encountered during skein winding and how do you troubleshoot them?

- Yarn breakage: Inspect the yarn for any weak points or knots. Check the tension control system and adjust accordingly.

- Uneven winding: Check the traverse mechanism for proper alignment and lubrication. Adjust the winding speed and tension.

- Skein tangling: Inspect the yarn for any loose ends or tangles. Adjust the tension control system to reduce tangling.

5. How do you maintain and calibrate the skein winding machine?

- Clean and lubricate the machine regularly.

- Inspect and replace any worn or damaged parts.

- Calibrate the machine according to the manufacturer’s instructions using a calibrated yarn meter.

6. What safety precautions should be taken when operating a skein winding machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep the work area clean and free of any tripping hazards.

- Never operate the machine with loose clothing or long hair that could get caught in the machinery.

7. Describe the importance of proper skein winding for yarn testing.

- Ensures accurate and consistent testing results.

- Helps identify any defects or variations in the yarn.

- Provides a standardized method for comparing different yarns.

8. What are the different types of skeins used for yarn testing?

- Lea skein: A skein of 120 yards used for testing cotton and wool yarns.

- Hank skein: A skein of 840 yards used for testing linen and jute yarns.

- Wrap skein: A skein of 1000 yards used for testing worsted and spun silk yarns.

9. What is the significance of the skein wrap and how do you ensure it is consistent?

- The skein wrap determines the number of turns per inch in the skein.

- Consistent wrap is essential for accurate testing.

- The wrap can be adjusted by changing the traverse rate of the winding machine.

10. What are some of the quality control checks you perform on the wound skeins before they are sent for testing?

- Visual inspection for any knots, breaks, or uneven winding.

- Measurement of skein length and weight to ensure compliance with specifications.

- Checking the skein wrap to ensure it meets the required standards.

11. How do you communicate any discrepancies or deviations from the standard with the relevant stakeholders?

- Report any issues promptly to the supervisor or quality control manager.

- Document the issue, including details of the discrepancy and any potential impact on testing results.

- Participate in meetings or discussions to resolve the issue and implement corrective actions.

12. How do you stay updated with the latest advancements and best practices in skein winding?

- Attend industry workshops and seminars.

- Read technical articles and manufacturer’s recommendations.

- Network with other Test Skein Winders and share knowledge.

13. What motivates you to excel in the role of a Test Skein Winder?

- Passion for ensuring the accuracy and reliability of yarn testing.

- Commitment to delivering high-quality work.

- Desire to contribute to the development of quality yarns.

14. How would you handle a situation where you are under pressure to wind skeins at a faster rate than what is allowed by the standard?

- Communicate the situation to the supervisor and explain the potential consequences of exceeding the standard.

- Work efficiently and maintain the required quality without compromising accuracy.

- Explore ways to optimize the winding process within the acceptable limits.

15. What are your career aspirations and how do you see the role of a Test Skein Winder contributing to your professional growth?

- Aspire to become a technical expert in yarn testing and quality control.

- Seek opportunities for training and advancement within the industry.

- Believe the role of a Test Skein Winder provides a solid foundation for understanding the intricacies of yarn manufacturing and testing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Test Skein Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Test Skein Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Test Skein Winder is responsible for performing a variety of tasks related to the winding and testing of yarn. This can include winding yarn into skeins, evaluating the yarn’s quality, and making sure that the yarn meets specifications.

1. Winding yarn into skeins

One of the main responsibilities of a Test Skein Winder is to wind yarn into skeins. This involves using a machine to wrap the yarn around a form to create a skein. The skein is then used to test the yarn’s quality and to determine its weight and length.

2. Evaluating the yarn’s quality

Test Skein Winders are also responsible for evaluating the yarn’s quality. This involves inspecting the yarn for any defects, such as broken fibers or unevenness. The winder will also test the yarn’s strength and elasticity to ensure that it meets specifications.

3. Making sure that the yarn meets specifications

In addition to winding and testing the yarn, Test Skein Winders are also responsible for making sure that the yarn meets specifications. This involves comparing the yarn to a set of standards to ensure that it is the correct weight, length, and quality.

4. Other responsibilities

In addition to the above responsibilities, Test Skein Winders may also be responsible for:

- Maintaining and calibrating winding and testing equipment

- Keeping records of yarn quality and production

- Providing training to other employees

Interview Tips

Preparing for an interview for a Test Skein Winder position can be daunting, but following a few simple tips can help you ace the interview and land the job.

1. Research the company and the position

Before you go on an interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture, goals, and needs, and to tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Test Skein Winder. Be prepared to talk about your previous experience in this role, as well as any relevant skills that you have, such as winding yarn, evaluating yarn quality, or maintaining winding and testing equipment.

4. Ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It also gives you an opportunity to learn more about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Test Skein Winder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!