Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Textile Colorist Formulator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

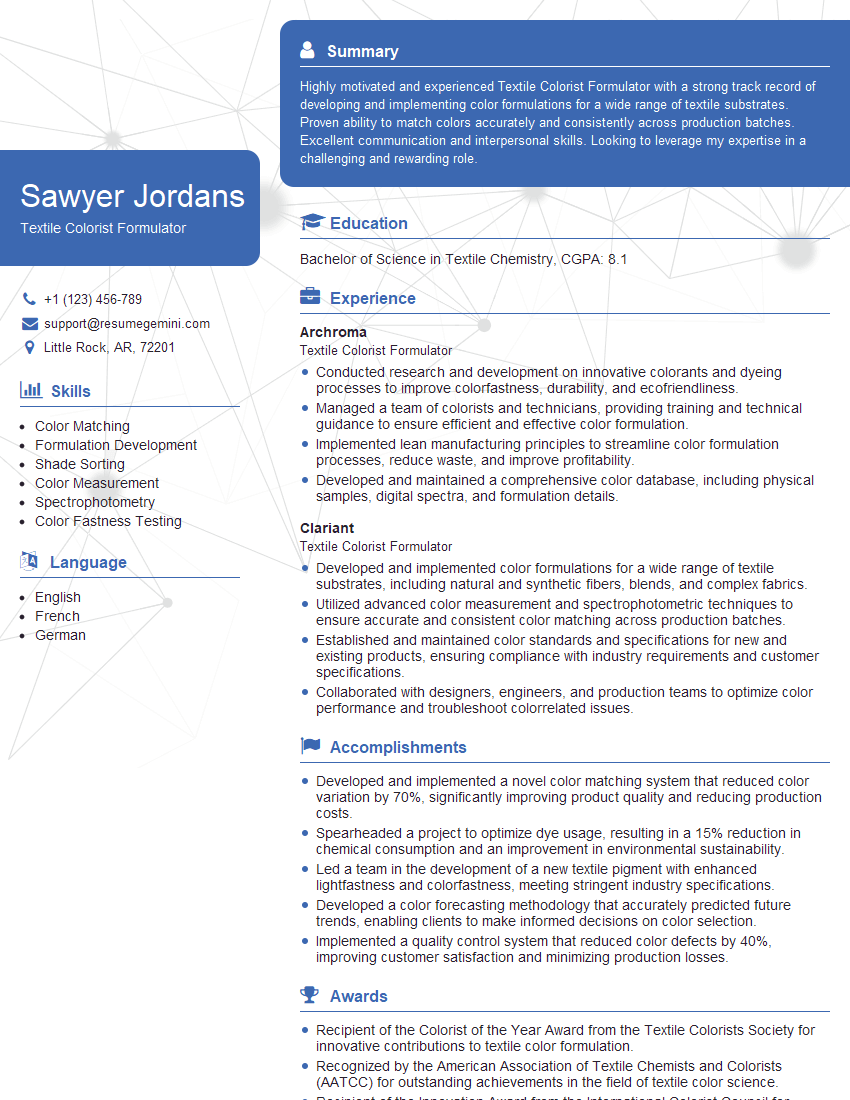

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Colorist Formulator

1. What are the key factors to consider when developing a new color formulation for textiles?

As a Textile Colorist Formulator, I would prioritize the following factors when creating a new color formulation for textiles:

- Substrate characteristics: Understanding the fiber content, weave structure, and surface texture of the textile is crucial for selecting appropriate dyes and auxiliaries.

- Desired color and shade: Accurately interpreting the customer’s color specifications and translating them into a precise shade requires expertise in color matching.

- Colorfastness requirements: Ensuring the color’s resistance to various conditions such as light, washing, and rubbing is essential to meet end-use performance specifications.

- Cost and availability: Optimizing the use of dyes and auxiliaries while considering their cost and availability helps maintain production efficiency.

- Environmental regulations: Adhering to industry regulations regarding the usage and disposal of dyes and chemicals is of utmost importance.

2. Describe your approach to color matching.

Understanding the Color Standard

- Thoroughly reviewing the customer’s color standard, including physical samples, digital representations, and color specifications.

- Analyzing the spectral data of the standard to identify the dominant wavelengths and their intensities.

Creating a Formulation Plan

- Selecting a suitable dye combination that can replicate the target color’s spectral characteristics.

- Determining the optimal dye concentrations based on the substrate’s affinity for the dyes.

- Adjusting the formulation to account for the effects of auxiliaries, pH, and dyeing conditions.

Testing and Evaluation

- Applying the formulated color to the substrate and evaluating its match to the standard under different lighting conditions.

- Conducting colorfastness tests to ensure the color’s durability as per customer specifications.

3. How do you handle color correction when there is a mismatch between the formulated color and the desired shade?

- Analyzing the color difference: Using spectrophotometers or visual assessment to determine the deviations in hue, saturation, and lightness.

- Adjusting the formulation: Modifying the dye concentrations, adding or removing dyes, or adjusting the auxiliaries to correct the color balance.

- Retesting and evaluation: Repeating the dyeing process with the corrected formulation and evaluating the color match until the desired shade is achieved.

- Documenting changes: Keeping a record of the color correction process and the final formulation adjustments for future reference and quality control.

4. Explain the role of shade sorting and metamerism in textile color matching.

- Shade sorting: Dividing textiles into groups based on their perceived color differences under specific lighting conditions, ensuring consistency within each shade band.

- Metamerism: The phenomenon where two colors appear to match under one light source but differ under another, making shade sorting challenging and necessitating careful lighting choices.

- Managing metamerism: Using spectrophotometers to measure color under multiple light sources, selecting dyes with low metameric index, and employing color correction techniques to minimize the impact of metamerism.

5. Describe the different methods used for evaluating colorfastness.

- Lightfastness: Testing the color’s resistance to fading caused by exposure to light, using standardized methods such as ISO 105-B02.

- Washing fastness: Evaluating the color’s ability to withstand various washing conditions, including laundering, bleaching, and dry cleaning, following methods like ISO 105-C06 and AATCC 61.

- Rubbing fastness: Assessing the color’s resistance to color transfer when subjected to friction, using methods such as ISO 105-X12 and AATCC 8.

- Perspiration fastness: Testing the color’s ability to withstand exposure to perspiration, both acidic and alkaline, using methods like ISO 105-E04 and AATCC 15.

6. How do you stay up-to-date with advancements in textile coloring technology?

- Attending industry conferences and workshops: Participating in events where experts share knowledge on the latest dyeing techniques, color measurement technologies, and sustainability practices.

- Reading technical journals and research papers: Staying informed about scientific advancements in color chemistry, dye synthesis, and textile manufacturing.

- Networking with professionals in the field: Engaging with colleagues, suppliers, and consultants to exchange ideas and learn about innovative approaches.

- Online learning and webinars: Participating in online courses and attending industry webinars to gain knowledge on specific topics and emerging technologies.

7. Describe your experience in using software tools for color formulation and color matching.

Throughout my career, I have extensively utilized industry-leading software tools to streamline and enhance my color formulation and matching processes:

- Color matching software: Employing software that utilizes spectrophotometer data and advanced algorithms to accurately predict the required dye combinations for achieving a desired color.

- Color management software: Utilizing software that allows for the creation and management of color palettes, ensuring consistency across different production batches and substrates.

- Color communication tools: Using software that facilitates the digital communication of color information, such as spectral data and colorimetric values, with stakeholders.

8. How do you ensure that your color formulations meet the required quality standards?

- Establishing clear quality parameters: Defining specific colorimetric and fastness requirements based on customer specifications and industry standards.

- Rigorous testing and validation: Conducting thorough testing of formulated colors against established parameters, utilizing spectrophotometers and standardized test methods.

- Process control and documentation: Implementing robust production processes that ensure consistent color reproduction and maintaining detailed records of all formulation and testing data.

- Regular calibration and maintenance: Calibrating equipment regularly and adhering to established maintenance schedules to ensure accurate color measurements and reliable results.

9. What are some of the challenges you have faced in textile color formulation and how did you overcome them?

Throughout my experience, I have encountered several challenges in textile color formulation, including:

- Subtle color differences: Matching colors that are very close to each other can be challenging. I overcome this by using precise color measurement tools and carefully adjusting the formulation.

- Metamerism: Dealing with the phenomenon of metamerism, where colors appear to match under one light source but differ under another, requires careful selection of dyes and consideration of the end-use conditions.

- Substrate variations: Different textiles have varying affinities for dyes, which can affect the color outcome. I address this by optimizing the formulation based on the specific substrate characteristics.

To overcome these challenges, I employ a combination of technical expertise, experimentation, and collaboration with colleagues. By leveraging my knowledge of color science and the latest industry techniques, I consistently deliver accurate and high-quality color formulations.

10. How do you approach sustainability in textile color formulation?

- Selecting eco-friendly dyes and auxiliaries: Opting for dyes and chemicals that minimize environmental impact, complying with industry regulations and certifications.

- Optimizing dye usage: Utilizing advanced color matching software to determine the optimal dye concentrations, reducing waste and minimizing costs.

- Water conservation: Implementing water-saving techniques during the dyeing process, such as low liquor ratio dyeing and efficient rinsing practices.

- Wastewater treatment: Collaborating with wastewater treatment facilities to ensure proper disposal and treatment of dye effluents, minimizing environmental pollution.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Colorist Formulator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Colorist Formulator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Textile Colorist Formulator is responsible for developing new colors and shades for textiles, ensuring color consistency, and maintaining high-quality standards. Key job responsibilities include:

1. Color Development and Formulation

Develop new color shades and formulations based on customer specifications, market trends, and fabric requirements.

- Conduct extensive research on dyes, pigments, and colorants.

- Experiment with different combinations and proportions to create desired colors and effects.

2. Color Matching and Adjustment

Match existing colors or create new shades based on customer samples or specifications.

- Analyze color samples using spectrophotometers and other instruments.

- Adjust formulations to achieve precise color matches or create slight variations.

3. Production Supervision

Supervise color application processes in the production environment to ensure color consistency.

- Monitor dye baths, pH levels, and other process parameters.

- Troubleshoot any color-related problems during production.

4. Quality Control

Establish and maintain quality standards for textile colors.

- Conduct colorfastness tests and other quality checks to ensure color durability.

- Document and report on color deviations and non-conformances.

Interview Tips

To ace the interview for a Textile Colorist Formulator position, candidates should:

1. Research the Company and Industry

Familiarize themselves with the company’s products, values, and target market.

- Research industry trends and technological advancements in textile coloration.

- Prepare questions that demonstrate their knowledge and interest in the company.

2. Highlight Experience and Skills

Emphasize relevant work experience and skills that align with the job requirements.

- Showcase expertise in color development, matching, and formulation.

- Highlight proficiency in using color measurement instruments and quality control techniques.

3. Demonstrate Problem-Solving Abilities

Provide examples of how they have solved color-related problems or improved production processes.

- Explain how they troubleshoot color issues and implement corrective actions.

- Share case studies that demonstrate their ability to meet customer color expectations.

4. Show Passion for Color

Convey their passion for color and their commitment to achieving exceptional color results.

- Discuss their inspiration and motivation for working in the field.

- Explain how they stay updated on the latest color trends and technologies.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Textile Colorist Formulator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!