Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Textile Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Textile Machine Operator so you can tailor your answers to impress potential employers.

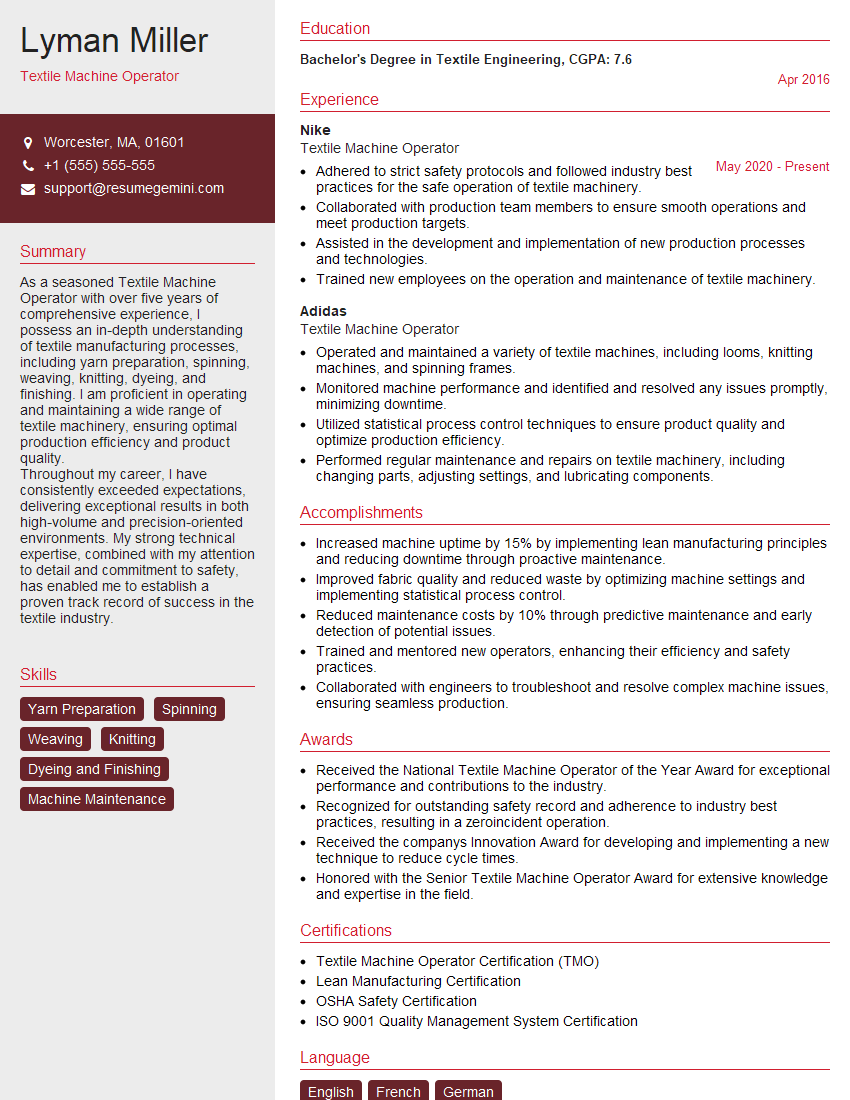

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Machine Operator

1. Describe the different types of textile machines you have operated?

In my previous role, I worked with a variety of textile machines, including

- Circular knitting machines

- Flat knitting machines

- Warp knitting machines

- Weaving machines

- Dyeing and finishing machines

2. What is the most important thing to consider when operating a textile machine?

Safety

- Follow all safety regulations and procedures

- Wear appropriate safety gear

- Inspect the machine before operating it

- Be aware of the machine’s surroundings

Efficiency

- Operate the machine at the correct speed and tension

- Use the correct materials and settings

- Monitor the machine’s performance

- Make adjustments as needed

Quality

- Produce products that meet the required specifications

- Inspect products for defects

- Make adjustments to the machine as needed

- Maintain a clean and organized work area

3. How do you troubleshoot a textile machine?

When troubleshooting a textile machine, I follow these steps:

- Identify the problem

- Check the machine’s manual or consult with a supervisor

- Inspect the machine for any visible damage or loose connections

- Test the machine’s components one at a time

- Replace any faulty components

4. What are the most common problems you have encountered when operating a textile machine?

The most common problems I have encountered when operating a textile machine are:

- Broken needles

- Yarn tension problems

- Fabric defects

- Machine breakdowns

- Electrical problems

5. How do you maintain a textile machine?

To maintain a textile machine, I perform the following tasks:

- Clean the machine regularly

- Lubricate the machine’s moving parts

- Inspect the machine for any damage or wear

- Replace any worn or damaged parts

- Calibrate the machine

- Keep a log of all maintenance activities

6. What are the safety precautions you must follow when working with textile machines?

When working with textile machines, I follow these safety precautions:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs

- Keep long hair and loose clothing away from moving parts

- Never operate a machine that is not properly guarded

- Be aware of the machine’s surroundings and potential hazards

- Follow all safety regulations and procedures

7. What is the difference between a loom and a knitting machine?

A loom is a machine that weaves fabric by interlacing two sets of yarns at right angles to each other. A knitting machine is a machine that knits fabric by forming loops of yarn.

8. What are the different types of fabrics that can be produced on a textile machine?

The different types of fabrics that can be produced on a textile machine include:

- Woven fabrics

- Knitted fabrics

- Nonwoven fabrics

- Technical fabrics

9. What are the key factors that affect the quality of a textile product?

The key factors that affect the quality of a textile product include:

- The quality of the raw materials

- The type of textile machine used

- The operating conditions of the textile machine

- The skill of the textile machine operator

- The quality control procedures

10. What are the latest trends in textile manufacturing?

The latest trends in textile manufacturing include:

- The use of sustainable materials

- The development of new and innovative textile technologies

- The increasing use of automation

- The growth of the global textile market

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Machine Operators play a crucial role in the textile manufacturing process, operating and maintaining machinery to produce various textile products. Their key job responsibilities include:

1. Machine Operation and Maintenance

Operate textile machines, such as looms, knitting machines, or finishing machines, to convert raw materials into fabrics or other textile products.

- Monitor machine performance, making adjustments to ensure optimal production.

- Perform routine maintenance tasks, such as cleaning, lubrication, and troubleshooting minor issues.

2. Quality Control

Inspect produced textiles for defects, such as uneven weave, holes, or color variations.

- Identify and mark defective products for removal from the production line.

- Assist in implementing quality control measures to improve product quality.

3. Production Coordination

Collaborate with other operators and supervisors to ensure smooth production flow.

- Receive instructions and materials from supervisors.

- Coordinate with other team members to troubleshoot production problems and optimize efficiency.

4. Safety Compliance

Adhere to all safety regulations and guidelines.

- Wear appropriate safety gear, such as gloves, safety glasses, and earplugs.

- Identify and report any potential hazards or safety concerns.

Interview Tips

To prepare for a Textile Machine Operator interview, candidates should follow these tips and hacks:

1. Research the Company and Position

- Visit the company’s website to learn about their products, services, and culture.

- Read online reviews or industry forums to gain insights into the company’s reputation.

- Review the job description thoroughly to understand the specific responsibilities and requirements of the position.

2. Practice Common Interview Questions

- Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”.

- Consider potential questions related to textile machine operation, maintenance, and quality control.

- Rehearse your answers out loud to improve fluency and confidence.

3. Highlight Relevant Skills and Experience

- Emphasize your experience operating and maintaining textile machines, including specific machine types.

- Showcase your knowledge of textile materials and production processes.

- Highlight any certifications or training you have in textile manufacturing or related fields.

4. Prepare Questions for the Interviewer

- Prepare thoughtful questions to ask the interviewer about the position, the company, and the industry.

- This demonstrates your interest and engagement in the opportunity.

- Ask questions that align with your research and show your understanding of the role.

Next Step:

Now that you’re armed with the knowledge of Textile Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Textile Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini