Feeling lost in a sea of interview questions? Landed that dream interview for Textile Pin Worker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Textile Pin Worker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

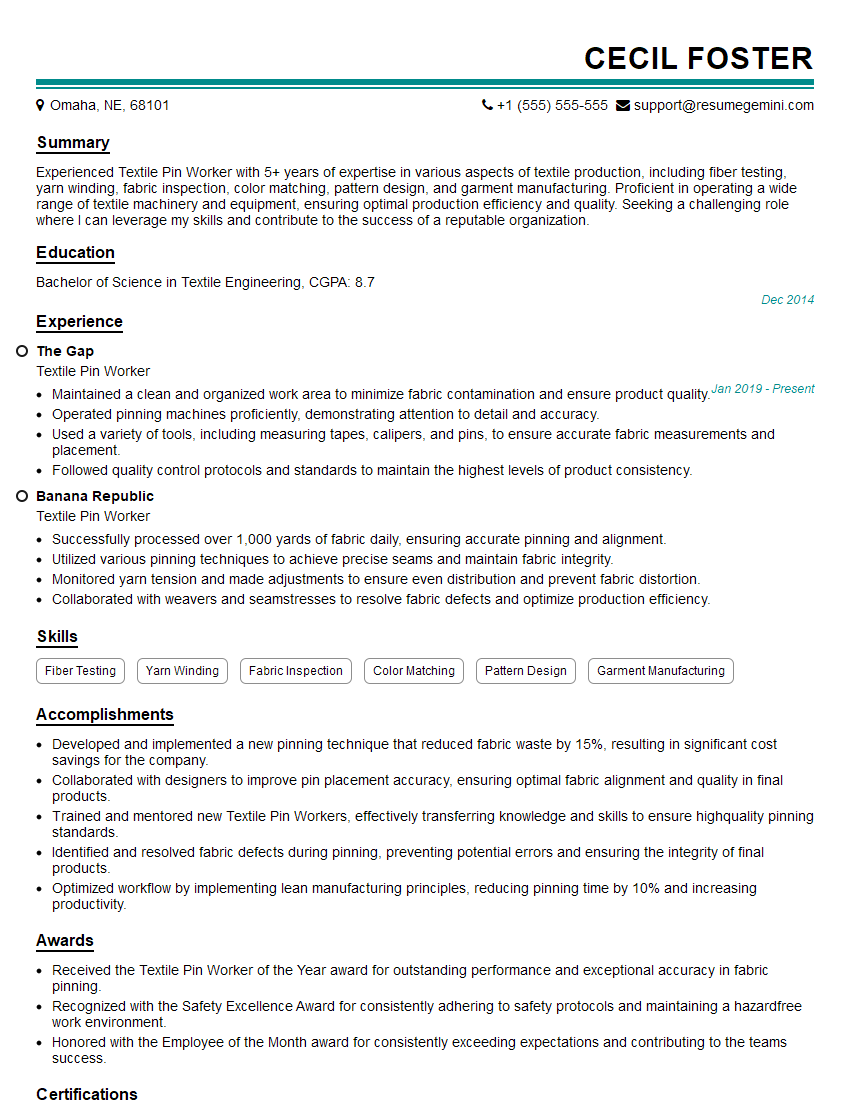

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Pin Worker

1. What are the different types of pins used in textile production?

In textile production, there are various types of pins used for specific purposes. Some common types include:

- T-pins: Thin and sharp pins with a T-shaped head, used for holding fabrics in place while sewing or pinning patterns.

- Ballpoint pins: Similar to T-pins but have a small ball at the end, which prevents snagging or tearing delicate fabrics.

- Quilting pins: Long and sturdy pins with a large head, designed for securing multiple layers of fabric in quilting projects.

- Glass head pins: Pins with a clear glass head that allows for easy visibility and removal.

- Safety pins: Closed pins with a hinge and locking mechanism, used for temporarily securing items without the risk of pricking.

2. How do you ensure that the pins are inserted properly into the fabric?

Alignment and Placement

- Align the pin perpendicular to the fabric surface.

- Insert the pin at the desired location, ensuring it is parallel to the seam line or pattern.

Pressure and Depth

- Apply gentle but firm pressure to insert the pin into the fabric.

- Insert the pin to an appropriate depth, ensuring it is secure but not too deep to damage the fabric.

Removal

- Grip the pin’s head and gently pull it out in the opposite direction of insertion.

- Avoid pulling the pin sideways to prevent tearing the fabric.

3. What are the safety precautions to follow when working with pins?

- Store pins in a safe and secure location: Keep pins in a closed container or pincushion when not in use to prevent accidental pricking.

- Dispose of bent or broken pins properly: Bent or broken pins can be dangerous and should be discarded in a designated sharps container.

- Never leave pins in clothing or fabric: Always remove pins before laundering or ironing to avoid injury or damage to the fabric.

- Be mindful of children and pets: Keep pins out of reach of children and pets to prevent accidental ingestion or punctures.

- Wear appropriate hand protection: Use thimbles or gloves when handling large quantities of pins to protect your fingers from pricks.

4. Describe the process of pinning fabric for a straight seam.

- Align the fabric edges: Place the two fabric edges to be sewn together, ensuring they are aligned and smooth.

- Insert pins perpendicularly: Holding the pins perpendicular to the fabric, insert them into the seam allowance at regular intervals.

- Space pins evenly: Distribute the pins evenly along the seam line, providing support and preventing the fabric from shifting during sewing.

- Secure the seam: Once the pins are inserted, gently pull the fabric to check if the seam is secure and there are no gaps.

- Remove pins as you sew: As you approach each pin while sewing, carefully remove it to avoid needle breakage.

5. What are the different techniques used to pin curves and corners in fabric?

Pinning Curves

- Clipping: Make small, evenly spaced clips along the seam allowance to create more flexibility.

- Easing: Gently stretch the fabric along the curve while pinning to allow it to conform to the shape.

Pinning Corners

- Mitering: Fold and press the seam allowance at the corner to create a 45-degree angle, then pin along the folded edges.

- Trimming: Trim excess fabric from the seam allowance at the corner to reduce bulk and facilitate pinning.

6. How do you use pins to secure pleats and gathers in fabric?

Securing Pleats

- Align the fabric edges to form the pleat.

- Fold the fabric along the pleat line and insert pins perpendicularly into the fold.

- Space the pins evenly to provide stability.

Securing Gathers

- Create gathers by pulling the thread ends of a running stitch.

- Pin the gathered fabric to the desired location.

- Distribute the gathers evenly by adjusting the spacing of the pins.

7. What is the purpose of using pins in pattern making?

- Holding patterns together: Pins secure pattern pieces to fabric or other materials for cutting and sewing.

- Marking darts and details: Pins can indicate the positions of darts, pockets, and other design elements on the fabric.

- Transferring markings: After pinning patterns to fabric, markings such as notches and darts can be transferred through the fabric.

- Adjusting patterns: Pins allow for adjustments to pattern pieces by temporarily attaching or removing fabric.

8. How do you maintain and clean pins to ensure their longevity?

- Regular cleaning: Periodically clean pins by soaking them in a solution of water and dish soap.

- Rust prevention: Dry pins thoroughly after cleaning to prevent rust formation. You can also apply a thin layer of oil to protect them.

- Sharpening: If pins become dull, you can sharpen them by inserting them into a pincushion filled with fine sand or emery powder.

- Proper storage: Store pins in a clean, dry container or pincushion to prevent damage and rust.

9. What are the common challenges faced by Textile Pin Workers, and how do you overcome them?

- Eye strain: Prolonged focus on detailed work can cause eye strain. Take regular breaks and use proper lighting.

- Finger fatigue: Repetitive pin insertion can lead to finger fatigue. Use ergonomic techniques and take breaks to reduce strain.

- Accuracy and precision: Pinning requires accuracy and precision. Pay attention to detail and double-check your work.

- Time management: Pinning can be time-consuming. Prioritize tasks and work efficiently to meet deadlines.

10. How do you stay updated on the latest techniques and best practices in Textile Pin Working?

- Industry publications: Read trade magazines and journals to learn about new techniques and innovations.

- Workshops and seminars: Attend industry events to gain hands-on experience and learn from experts.

- Online resources: Utilize online platforms, forums, and tutorials to access information and connect with other professionals.

- Mentorship: Seek guidance from experienced Textile Pin Workers to learn best practices and stay current.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Pin Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Pin Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Pin Workers play a crucial role in the textile industry, ensuring the efficient operation of machinery and the production of high-quality textile products. Their key responsibilities include:

1. Machine Operation

Operate and monitor textile pin machines, ensuring they run smoothly and efficiently.

- Load and unload textile fabrics onto the machine.

- Adjust machine settings, such as speed and tension, to produce high-quality fabrics.

2. Fabric Inspection

Inspect fabrics before and after processing, identifying and removing any defects.

- Detect and mark any flaws, such as holes, stains, or wrinkles.

- Sort fabrics based on quality and specifications.

3. Machine Maintenance

Perform routine maintenance and cleaning on textile pin machines to ensure optimal performance.

- Clean and lubricate machine parts.

- Replace worn or damaged components.

4. Quality Control

Monitor the quality of fabrics produced and identify any potential issues.

- Conduct periodic checks on fabric quality, using gauges and testing equipment.

- Report any quality concerns to supervisors.

Interview Tips

Preparing thoroughly for an interview is essential for making a great impression and increasing your chances of landing the job. Here are some interview tips for Textile Pin Workers:

1. Research the Company and Industry

Before the interview, take time to research the company you’re applying to and the textile industry as a whole. This knowledge will help you demonstrate your interest and understanding of the field.

- Visit the company’s website to learn about their products, services, and values.

- Read industry-related articles and news to stay updated on current trends and technologies.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. This will help you feel more confident and articulate during the interview.

- Practice answering questions about your experience, skills, and why you’re interested in the role.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and concise examples of your work experience.

Example Outline: * Situation: Describe a specific situation or challenge you faced in a previous role. * Task: Explain the task or responsibility you were assigned. * Action: Detail the steps you took to complete the task. * Result: Quantify or describe the positive outcomes of your actions.

3. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This demonstrates your respect for the interviewer and the company.

- Wear business casual attire, such as a button-down shirt or blouse and dress pants.

- Arrive 10-15 minutes early to give yourself time to settle in and compose yourself.

4. Be Enthusiastic and Positive

Throughout the interview, maintain a positive and enthusiastic attitude. This will show the interviewer that you’re genuinely interested in the role and the company.

- Smile, make eye contact, and speak clearly.

- Highlight your passion for the textile industry and your eagerness to contribute to the company.

5. Ask Thoughtful Questions

At the end of the interview, prepare a few thoughtful questions to ask the interviewer. This shows that you’re engaged and interested in learning more about the role and the company.

- Ask about the specific responsibilities of the role.

- Inquire about the company’s growth plans and future goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Textile Pin Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.