Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Textile Slitting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

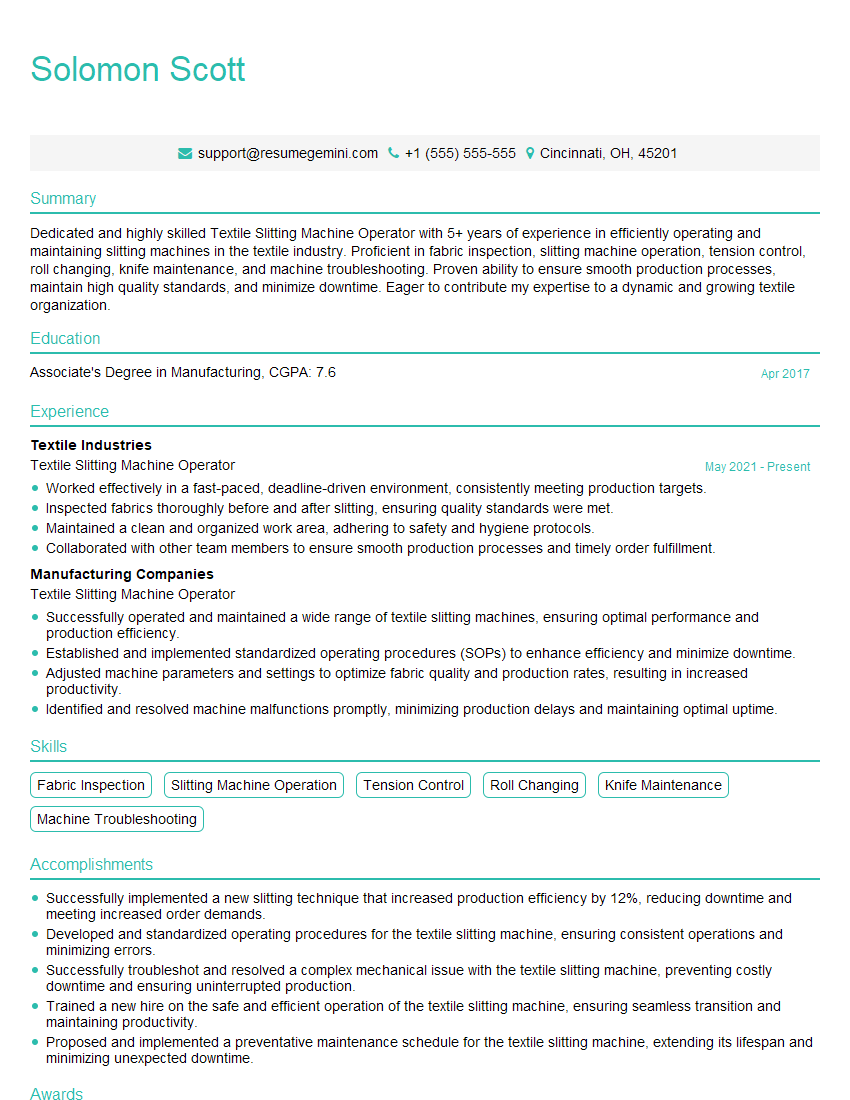

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Slitting Machine Operator

1. What are the different types of textile slitting machines?

There are various types of textile slitting machines, including:

- Rewinder Slitters: Unwind and rewind material onto rolls while slitting it into narrower widths.

- Shear Slitters: Use shear blades to cut material cleanly and precisely, producing high-quality slits.

- Razor Slitters: Employ razor blades for fine and detailed slitting, ideal for delicate materials like lace.

- Laser Slitters: Utilize lasers to cut materials with precision and minimal fraying, reducing waste.

- Ultrasonic Slitters: Generate high-frequency vibrations to cut materials, resulting in clean edges and sealed seams.

2. What are the key factors to consider when selecting a textile slitting machine?

Criteria for Machine Selection

- Material Type: Determine the compatibility of the machine with the specific textile material being slit.

- Slitting Width and Accuracy: Ensure the machine can achieve the desired slit widths and maintain precision.

- Speed and Efficiency: Consider the production volume and required speed of the slitting process.

- Tension Control: Assess the machine’s ability to control tension during slitting to prevent material distortion.

- Automation and Features: Evaluate the level of automation and additional features, such as edge trimming or roll handling.

3. What are the common problems encountered when operating a textile slitting machine, and how do you troubleshoot them?

Troubleshooting Common Issues:

- Uneven Slits: Check blade alignment, tension settings, and material quality.

- Material Jams: Inspect material tension, guide rollers, and blade sharpness.

- Blade Damage: Replace worn or damaged blades promptly.

- Roll Defects: Adjust tension settings, check core alignment, and inspect the material for flaws.

- Machine Vibration: Ensure proper machine leveling, tighten loose bolts, and check for unbalanced components.

4. How do you maintain a textile slitting machine to ensure optimal performance?

Maintenance Best Practices:

- Regular Cleaning: Remove dust and debris from the machine and blades.

- Blade Sharpening or Replacement: Keep blades sharp to maintain slitting quality.

- Tension Monitoring: Calibrate tension settings regularly to prevent material distortion.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear.

- Electrical Inspections: Check wiring and electrical connections for safety and efficiency.

5. What are the safety precautions to observe when operating a textile slitting machine?

Ensuring Operator Safety:

- Wear appropriate safety gear, including gloves and eye protection.

- Keep hands away from moving blades and rotating parts.

- Securely fasten materials before operating the machine.

- Avoid loose clothing or jewelry that could get caught in the machine.

- Follow established lockout/tagout procedures when servicing or repairing the machine.

6. How do you handle and dispose of textile waste generated by the slitting process?

Waste Management Practices:

- Collect waste material in designated containers.

- Comply with local regulations for waste disposal.

- Consider recycling or repurposing waste materials where possible.

- Maintain a clean and organized work area to minimize waste accumulation.

- Educate colleagues on proper waste handling techniques.

7. What is the importance of maintaining accurate records and documentation for textile slitting operations?

Benefits of Accurate Records:

- Process Monitoring: Track production data, identify areas for improvement, and ensure quality control.

- Compliance and Traceability: Meet industry standards and regulations, and provide traceability for materials and products.

- Maintenance Scheduling: Plan and schedule maintenance activities based on usage and performance data.

- Training and Troubleshooting: Provide documentation for training new operators and troubleshooting potential issues.

- Communication and Reporting: Facilitate clear communication and reporting of production details to supervisors and management.

8. How do you stay updated on the latest advancements in textile slitting technology?

Staying Current with Technology:

- Attend industry conferences and exhibitions.

- Read technical journals and industry publications.

- Engage in online forums and discussion groups.

- Consult with equipment manufacturers and distributors.

- Participate in training and development programs.

9. Give us an example of a time when you successfully resolved a complex issue with a textile slitting machine.

Troubleshooting Success Story:

- Describe the issue encountered, including symptoms and potential causes.

- Explain the diagnostic steps taken to identify the root cause.

- Detail the solution implemented to resolve the issue.

- Highlight the impact of the solution, such as improved machine performance or reduced downtime.

10. How would you approach optimizing the performance of a textile slitting machine for a specific material?

Optimizing Machine Performance:

- Analyze the material properties and характеристиками.

- Adjust machine settings, such as tension, speed, and blade type, to suit the material.

- Conduct test runs to evaluate the results and make further adjustments as needed.

- Monitor performance metrics, such as slit quality, efficiency, and waste generation.

- Fine-tune the machine parameters to achieve optimal performance for the specific material.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Slitting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Slitting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Slitting Machine Operators play a crucial role in the textile manufacturing industry, operating highly specialized machinery to cut and trim textiles with precision. Their primary responsibilities include:

1. Operating Textile Slitting Machines

– Set up, calibrate, and operate textile slitting machines to cut and trim fabrics into narrow strips or rolls

– Adjust machine settings to ensure accurate cuts and minimize waste

– Monitor machine performance and identify potential issues or malfunctions

2. Preparing and Inspecting Textiles

– Prepare textiles for slitting, including unwinding rolls, aligning edges, and ensuring proper tension

– Inspect textiles for defects or imperfections that could affect slitting quality

– Maintain clean and organized work area to minimize contamination or damage to textiles

3. Monitoring Production and Quality

– Monitor slitting process to ensure smooth operation and adherence to specifications

– Check cut quality and dimensions to meet customer requirements

– Collect and document production data for quality control and optimization purposes

4. Maintaining and Troubleshooting Machinery

– Perform routine maintenance and cleaning of slitting machines

– Identify and troubleshoot machine malfunctions or breakdowns

– Collaborate with maintenance technicians to resolve technical issues and maintain machine efficiency

Interview Tips

Preparing for a Textile Slitting Machine Operator interview requires both technical knowledge and effective communication skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, mission, and industry trends. Demonstrate your interest and enthusiasm for the textile manufacturing field.

- Identify specific areas where your skills and experience align with the company’s needs.

- Research common industry practices and technological advancements related to textile slitting.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining textile slitting machines. Quantify your experience with specific machine models and discuss your troubleshooting abilities.

- Provide examples of how you have optimized machine settings to improve cut quality or reduce waste.

- Demonstrate your knowledge of textile materials and their handling requirements.

3. Showcase Your Attention to Detail

Textile slitting requires precision and attention to detail. Highlight your ability to inspect textiles for defects, ensure accurate cuts, and maintain high quality standards.

- Discuss your quality control procedures and how you ensure compliance with customer specifications.

- Explain how you handle textiles with special requirements or delicate fabrics.

4. Prepare for Behavioral Questions

Interviewers often ask behavioral questions to assess your soft skills and work ethic. Prepare examples that demonstrate your ability to work independently, solve problems, and collaborate effectively.

- Describe a situation where you identified and resolved a machine malfunction.

- Discuss how you handle tight deadlines or unexpected production challenges.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Textile Slitting Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.