Are you gearing up for an interview for a Textile Worker position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Textile Worker and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

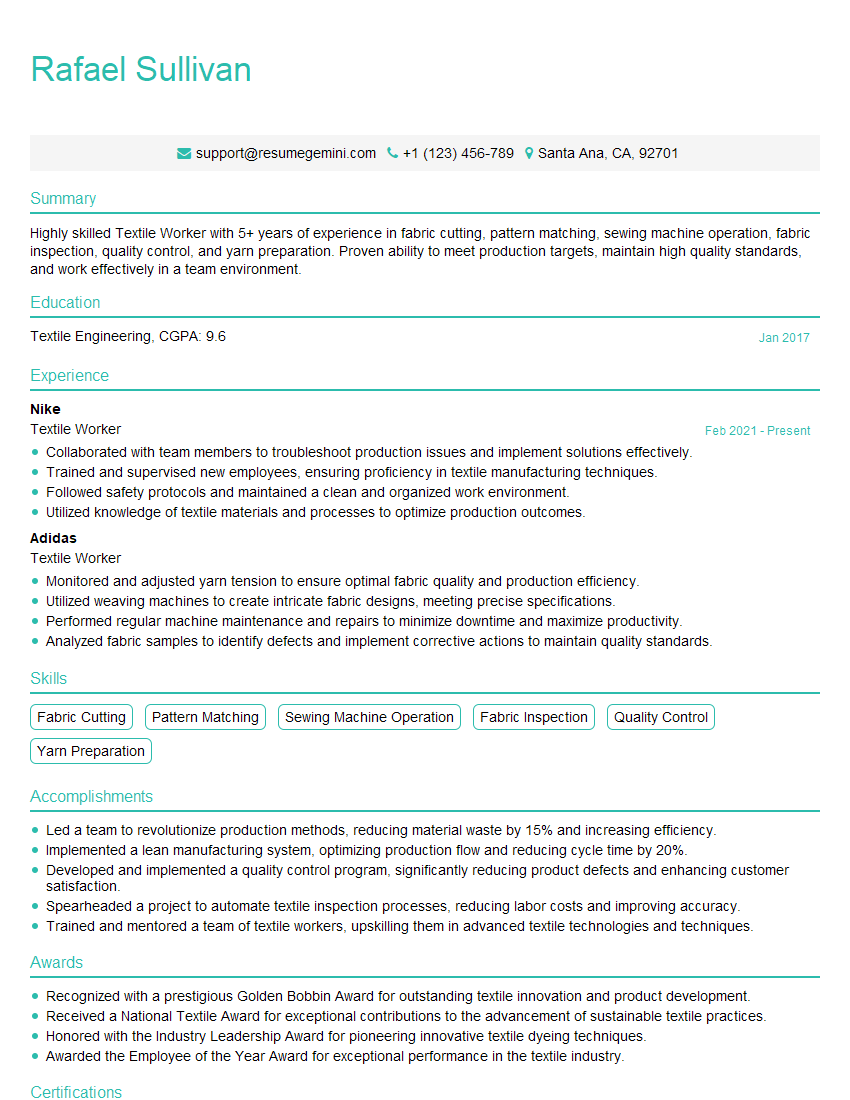

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Textile Worker

1. What types of textile manufacturing processes are you familiar with?

I am familiar with a variety of textile manufacturing processes, including:

- Spinning: I have experience in both ring spinning and rotor spinning.

- Weaving: I am proficient in operating a variety of weaving machines, including air jet looms, water jet looms, and rapier looms.

- Knitting: I have experience in both weft knitting and warp knitting.

- Dyeing and finishing: I am familiar with a variety of dyeing and finishing techniques, including dyeing, printing, and finishing.

2. What are the key factors that affect the quality of textile products?

Fiber quality

- The quality of the fibers used in a textile product can have a significant impact on the overall quality of the product.

- Some of the key factors that affect fiber quality include the length, strength, and fineness of the fibers.

Manufacturing process

- The manufacturing process also plays a key role in determining the quality of a textile product.

- Factors such as the type of machinery used, the skill of the workers, and the quality control measures in place can all affect the final quality of the product.

3. What are the different types of textile defects and how do you identify them?

There are a variety of different types of textile defects, including:

- Yarn defects: These defects can occur during the spinning process and can include things like uneven yarn, slubs, and neps.

- Weaving defects: These defects can occur during the weaving process and can include things like broken threads, mispicks, and floats.

- Knitting defects: These defects can occur during the knitting process and can include things like dropped stitches, runs, and snags.

- Dyeing and finishing defects: These defects can occur during the dyeing and finishing process and can include things like uneven dyeing, color bleeding, and shrinkage.

I am able to identify textile defects by visually inspecting the fabric and by using a variety of testing methods.

4. What are the different types of textile testing methods and when are they used?

There are a variety of different textile testing methods that can be used to assess the quality of a textile product. Some of the most common testing methods include:

- Tensile testing: This test measures the strength of a textile fabric by applying a force to it until it breaks.

- Tear testing: This test measures the resistance of a textile fabric to tearing by applying a force to it until it tears.

- Abrasion testing: This test measures the resistance of a textile fabric to abrasion by rubbing it against a rough surface.

- Colorfastness testing: This test measures the resistance of a textile fabric to fading by exposing it to light, water, and other elements.

The type of testing method used will depend on the specific properties of the textile product that are being tested.

5. What are the different types of textile machinery and what are their functions?

There are a variety of different types of textile machinery used in the textile industry. Some of the most common types of machinery include:

- Spinning machines: These machines are used to create yarn from fibers.

- Weaving machines: These machines are used to create fabric from yarn.

- Knitting machines: These machines are used to create fabric from yarn.

- Dyeing machines: These machines are used to dye fabric.

- Finishing machines: These machines are used to finish fabric, such as by applying a coating or printing a pattern.

each type of machinery has its own specific function and is used to create different types of textile products.

6. What are the safety precautions that should be taken when working with textile machinery?

There are a number of safety precautions that should be taken when working with textile machinery. Some of the most important precautions include:

- Always wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Never operate machinery that you are not trained to operate.

- Keep your work area clean and free of debris.

- Be aware of the moving parts of machinery and keep your hands and other body parts away from them.

- Report any unsafe conditions or equipment to your supervisor immediately.

7. What are the different types of textile fibers and what are their properties?

There are a variety of different types of textile fibers, each with its own unique properties. Some of the most common types of textile fibers include:

- Natural fibers: These fibers are derived from plants or animals. Some of the most common natural fibers include cotton, wool, silk, and linen.

- Man-made fibers: These fibers are created from synthetic materials. Some of the most common man-made fibers include polyester, nylon, and acrylic.

The type of fiber used in a textile product will depend on the desired properties of the product, such as strength, durability, comfort, and appearance.

8. What are the different types of textile dyes and how are they used?

There are a variety of different types of textile dyes, each with its own unique properties. Some of the most common types of textile dyes include:

- Acid dyes: These dyes are used to dye wool, silk, and nylon.

- Basic dyes: These dyes are used to dye cotton, linen, and rayon.

- Disperse dyes: These dyes are used to dye polyester and acetate.

- Reactive dyes: These dyes are used to dye cotton, linen, and rayon.

- Vat dyes: These dyes are used to dye cotton, linen, and rayon.

The type of dye used in a textile product will depend on the desired color and the type of fabric being dyed.

9. What are the different types of textile finishes and how are they applied?

There are a variety of different types of textile finishes, each with its own unique properties. Some of the most common types of textile finishes include:

- Anti-wrinkle finishes: These finishes help to prevent wrinkles from forming in fabrics.

- Water-repellent finishes: These finishes help to repel water from fabrics.

- Stain-resistant finishes: These finishes help to prevent stains from forming on fabrics.

- Fire-resistant finishes: These finishes help to prevent fabrics from catching fire.

- Antimicrobial finishes: These finishes help to prevent the growth of bacteria and other microorganisms on fabrics.

The type of finish applied to a textile product will depend on the desired properties of the product.

10. What are the latest trends in the textile industry?

The textile industry is constantly evolving, with new technologies and innovations being introduced all the time. Some of the latest trends in the textile industry include:

- The use of sustainable materials: Textile manufacturers are increasingly using sustainable materials, such as recycled polyester and organic cotton, in their products.

- The development of new technologies: New technologies, such as digital printing and 3D weaving, are being used to create new and innovative textile products.

- The growth of e-commerce: E-commerce is becoming increasingly popular for the purchase of textile products, as it offers consumers a convenient and easy way to shop.

These trends are shaping the future of the textile industry, and it is important for textile workers to be aware of them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Textile Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Textile Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Textile Workers are responsible for a variety of tasks in the production of textiles, from weaving and knitting to dyeing and finishing. Their duties may vary depending on the specific industry and job title, but some of the most common responsibilities include:

1. Operating Textile Machinery

Textile Workers must be able to operate a variety of textile machinery, including looms, knitting machines, and dyeing equipment. They must be able to set up and adjust these machines to produce the desired results.

- Set up and operate looms, knitting machines, and other textile machinery

- Monitor the production process and make adjustments as needed

2. Inspecting Textile Products

Textile Workers must be able to inspect textile products to ensure that they meet quality standards. They must be able to identify defects and make repairs as necessary.

- Inspect textile products for defects

- Make repairs to defective products

3. Maintaining a Clean and Safe Work Area

Textile Workers must be able to maintain a clean and safe work area. They must be able to clean and maintain machinery, and they must be able to follow safety procedures.

- Clean and maintain machinery

- Follow safety procedures

4. Working as Part of a Team

Textile Workers often work as part of a team to produce textiles. They must be able to communicate effectively with other team members and they must be able to work together to achieve common goals.

- Communicate effectively with other team members

- Work together to achieve common goals

Interview Tips

In order to ace the interview for a Textile Worker position, it is important to be well-prepared. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before you go to the interview, it is important to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read articles about the company

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Tell me about yourself.

- Why are you interested in this position?

3. Dress Professionally

It is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you are making an effort to make a good impression.

- Wear a suit or business casual attire

- Make sure your clothes are clean and pressed

4. Be Yourself

The most important tip is to be yourself. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just relax and be yourself, and let your personality shine through.

- Don’t try to be someone you’re not

- Let your personality shine through

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Textile Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!