Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Texturing Machine Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

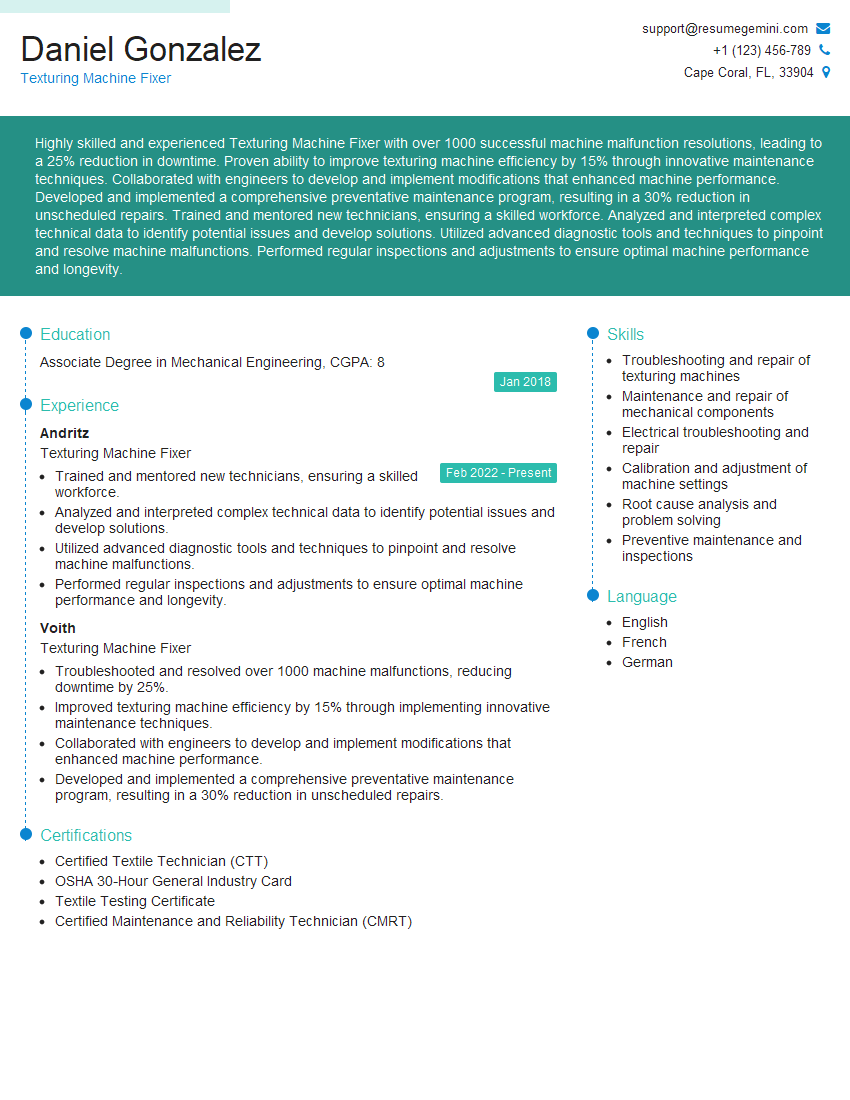

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Texturing Machine Fixer

1. What are the common problems that occur in texturing machines and how do you troubleshoot them?

Common problems include:

- Yarn breakage due to incorrect tension or damaged machine parts

- Uneven texturing due to faulty sensors or blocked nozzles

- Mechanical failures like bearing wear or motor issues

Troubleshooting involves:

- Visual inspection to identify any obvious issues

- Using diagnostic tools to check electrical and mechanical parameters

- Replacing worn or damaged parts, adjusting settings, or performing repairs

2. How do you ensure the proper alignment and tension of the yarn during the texturing process?

Yarn Alignment

- Checking the alignment of yarn guides and tensioners

- Using laser or mechanical alignment tools to ensure precise positioning

- Adjusting guide rollers and tensioners to minimize yarn drift

Yarn Tension

- Monitoring yarn tension using tension sensors or gauges

- Adjusting the tension settings on the machine to maintain optimal tension

- Checking for any yarn slippage or breakage caused by improper tension

3. Explain the different types of texturing methods and their principles of operation.

- Air Texturing: Uses high-velocity air jets to create loops and curls in the yarn

- Mechanical Texturing: Employs mechanical devices like gears, rollers, and crimping units to impart texture

- Stuffer Box Texturing: Involves using a stuffer box to create textured effects by compressing and twisting the yarn

- Chemical Texturing: Uses chemical treatments to alter the yarn structure, resulting in changes in texture and feel

4. How do you calibrate and maintain the temperature and humidity levels in the texturing machine?

- Using temperature and humidity sensors to monitor the conditions

- Adjusting the humidifier or dehumidifier settings to maintain the desired levels

- Calibrating the sensors periodically to ensure accuracy

- Performing regular maintenance on heating and cooling systems to prevent malfunctions

5. Describe the safety precautions you observe while operating and maintaining texturing machines.

- Wearing appropriate safety gear like gloves, eye protection, and earplugs

- Following lockout/tagout procedures before performing any maintenance work

- Ensuring the machine is properly grounded to prevent electrical hazards

- Keeping the work area clean and free of tripping hazards

- Reporting any safety concerns or incidents to the supervisor immediately

6. What are the key performance indicators (KPIs) used to measure the efficiency of a texturing machine and how do you monitor them?

- Production Rate: Number of textured yarns produced per hour

- Yarn Quality: Uniformity, strength, and texture of the yarns

- Machine Uptime: Percentage of time the machine is operational

- Waste Reduction: Amount of unusable yarn generated during operation

- Energy Consumption: Power usage of the machine

Monitoring involves using dashboards, software, and physical inspections to track these KPIs and identify areas for improvement.

7. Explain the role of sensors and control systems in the operation of texturing machines.

Sensors

- Monitor temperature, humidity, tension, and other process parameters

- Provide feedback to the control system for adjustments and optimization

Control Systems

- Use sensor data to regulate machine settings and ensure stable operation

- Implement algorithms to optimize texturing processes and improve efficiency

8. How do you interact with the production team and other departments to ensure smooth production?

- Coordinating with operators to monitor machine performance and resolve issues

- Consulting with quality control personnel to ensure yarn quality meets specifications

- Communicating with maintenance teams for scheduled maintenance and repairs

- Collaborating with management to discuss production targets and improvements

9. Describe a situation where you had to troubleshoot a complex problem on a texturing machine.

Provide a detailed account of the following:

- Problem encountered and its symptoms

- Steps taken to diagnose the issue

- Methods used to resolve the problem

- Outcome and lessons learned

10. How do you stay updated with the latest advancements in texturing technology?

- Attending industry conferences and workshops

- Reading technical articles and publications

- Consulting with equipment manufacturers and vendors

- Participating in online forums and discussions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Texturing Machine Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Texturing Machine Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Texturing Machine Fixer plays a crucial role in maintaining the smooth operation of texturing machines used in the textile industry. Their primary responsibilities include:

1. Machine Maintenance and Repair

Inspecting and diagnosing faults in texturing machines, including mechanical, electrical, and pneumatic systems.

- Performing preventive maintenance to ensure optimal machine performance.

- Carrying out repairs and replacements of faulty components.

2. Quality Control

Monitoring the operation of texturing machines to ensure the production of high-quality materials according to specifications.

- Adjusting machine parameters to optimize texture quality.

- Conducting tests and inspections to verify the quality of textured yarns.

3. Troubleshooting and Problem-Solving

Analyzing and diagnosing complex machine malfunctions.

- Identifying root causes of problems and implementing solutions.

- Collaborating with other technicians and engineers to resolve technical issues.

4. Training and Supervision

Training and mentoring junior technicians on machine operation and maintenance.

- Supervising and coordinating maintenance activities to ensure efficient workflow.

- Providing guidance and support to other employees.

Interview Tips

To ace your interview for a Texturing Machine Fixer position, consider the following tips:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This shows your interest and knowledge of the industry.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay up-to-date on advancements in texturing technology.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills related to machine maintenance, repair, and troubleshooting.

- Quantify your accomplishments with specific metrics, such as the number of machines repaired or the percentage of downtime reduced.

- Discuss any experience with specific types of texturing machines or industry-related certifications.

3. Showcase Problem-Solving Abilities

Share examples of successful problem-solving and troubleshooting experiences.

- Describe how you analyzed a complex machine issue, identified the root cause, and implemented a solution.

- Emphasize your ability to work independently and take initiative in resolving technical challenges.

4. Prepare for Technical Questions

Expect technical questions related to texturing machines, their operation, and maintenance.

- Review common machine components, troubleshooting procedures, and industry best practices.

- Consider practicing your answers to mock interview questions to build confidence.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Texturing Machine Fixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Texturing Machine Fixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.