Are you gearing up for a career in Thermal Cutting Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Thermal Cutting Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

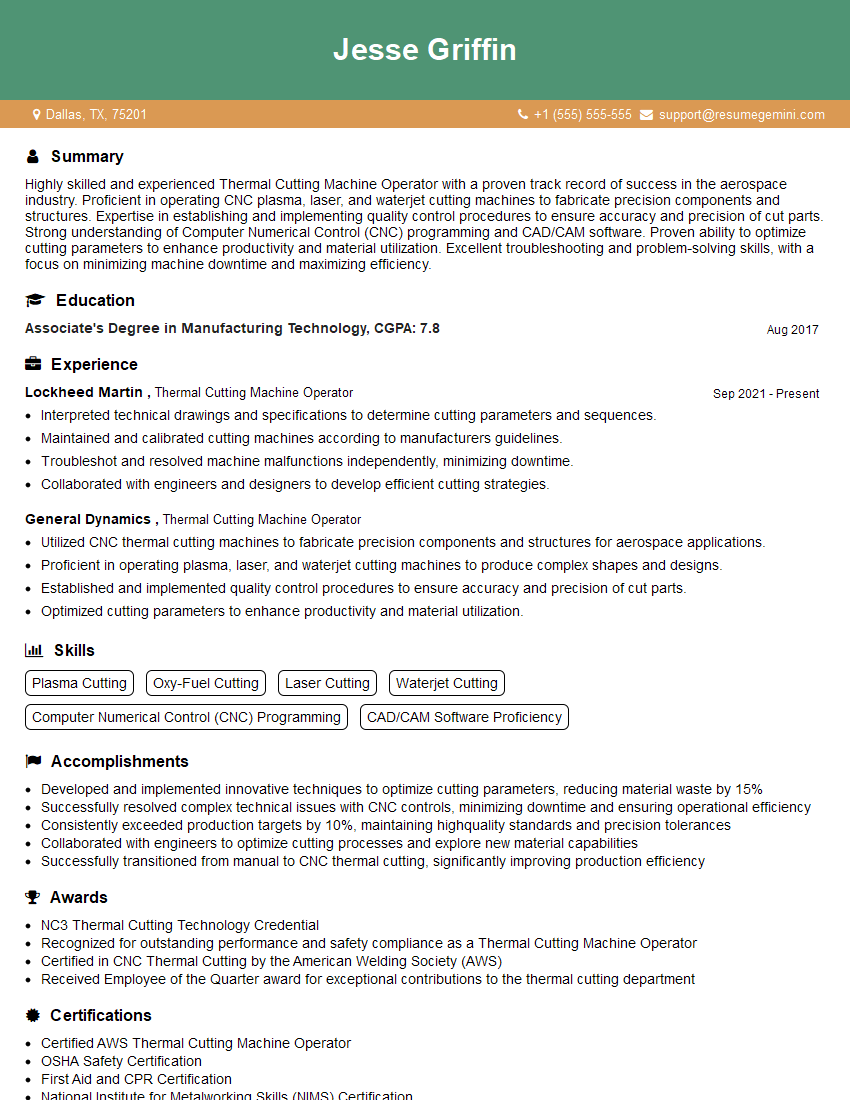

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermal Cutting Machine Operator

1. Explain the different types of thermal cutting processes and their applications.

- Plasma cutting: Uses a plasma torch to create a high-temperature, ionized gas that melts and cuts through the metal.

- Laser cutting: Uses a high-power laser beam to vaporize the metal.

- Waterjet cutting: Uses a high-pressure stream of water to cut through the metal.

- Oxy-fuel cutting: Uses a mixture of oxygen and fuel gas to create a high-temperature flame that melts and cuts through the metal.

2. What are the key factors to consider when selecting a thermal cutting process?

Material thickness

- Plasma cutting: Up to 100 mm

- Laser cutting: Up to 25 mm

- Waterjet cutting: Up to 150 mm

- Oxy-fuel cutting: Up to 300 mm

Material type

- Plasma cutting: Ferrous and non-ferrous metals

- Laser cutting: Ferrous and non-ferrous metals, plastics, and wood

- Waterjet cutting: Any material that can be cut with water

- Oxy-fuel cutting: Ferrous metals only

Cut quality

- Plasma cutting: Good cut quality, but can leave a dross on the cut edge

- Laser cutting: Excellent cut quality, with no dross

- Waterjet cutting: Good cut quality, but can leave a waterline on the cut edge

- Oxy-fuel cutting: Poor cut quality, with a large heat-affected zone

3. What are the safety precautions that must be taken when operating a thermal cutting machine?

- Wear appropriate personal protective equipment, including gloves, goggles, and a respirator.

- Ensure that the machine is properly grounded.

- Keep the work area clean and free of flammable materials.

- Never operate the machine in a confined space.

- Be aware of the potential for sparks and flying debris.

4. How do you maintain a thermal cutting machine?

- Regularly clean the machine and its components.

- Inspect the machine for wear and tear.

- Calibrate the machine regularly.

- Lubricate the machine according to the manufacturer’s instructions.

- Follow the manufacturer’s recommended maintenance schedule.

5. What are the different types of gases used in thermal cutting?

- Oxygen: Used in oxy-fuel cutting

- Nitrogen: Used in plasma cutting

- Argon: Used in laser cutting

- Carbon dioxide: Used in laser cutting

- Water: Used in waterjet cutting

6. What are the different types of nozzles used in plasma cutting?

- Single-piece nozzles

- Two-piece nozzles

- Three-piece nozzles

7. What are the different types of CNC controls used in thermal cutting machines?

- Manual controls

- Semi-automatic controls

- Automatic controls

8. What are the different types of software used in thermal cutting machines?

- CAM (computer-aided manufacturing) software

- CAD (computer-aided design) software

- CNC (computer numerical control) software

9. What are the different types of materials that can be cut with a thermal cutting machine?

- Metals

- Plastics

- Wood

- Composite materials

10. What are the different types of industries that use thermal cutting machines?

- Automotive

- Aerospace

- Construction

- Shipbuilding

- Fabrication

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermal Cutting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermal Cutting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thermal Cutting Machine Operators are responsible for operating and maintaining thermal cutting machines used to cut metal and other materials. They play a crucial role in various industries, including manufacturing, metal fabrication, and construction.

1. Machine Operation and Setup

Operate thermal cutting machines, such as plasma, laser, or oxy-fuel cutters, according to established procedures and specifications.

- Load and secure materials into the cutting machine.

- Program and calibrate the machine based on the required cutting parameters.

- Monitor and adjust machine settings to ensure optimal cutting quality.

2. Cutting Process Control

Execute cutting operations by following established processes and techniques.

- Interpret drawings and cutting instructions to determine the appropriate cutting path.

- Inspect cut pieces to ensure they meet specifications and quality standards.

- Adjust cutting parameters as needed to achieve precise and consistent results.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting of thermal cutting machines.

- Clean and inspect machines regularly to prevent breakdowns.

- Identify and resolve any malfunctions or performance issues.

- Coordinate with maintenance personnel for major repairs or replacements.

4. Safety and Environment

Adhere to all safety regulations and guidelines related to thermal cutting operations.

- Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and fire-resistant clothing.

- Follow proper ventilation and exhaust procedures to minimize exposure to fumes and airborne particles.

- Maintain a clean and organized work area to prevent accidents.

Interview Tips

To ace your interview for a Thermal Cutting Machine Operator position, follow these preparation tips and interview hacks:

1. Research the Company and Industry

Learn about the company’s history, products, and services. Demonstrate your knowledge of the industry and its trends. This shows the interviewer that you are genuinely interested in the opportunity and have taken the time to understand the context of the role.

2. Practice Your Skills

Review thermal cutting techniques, machine operation, and safety procedures. If possible, practice operating a thermal cutting machine or simulate the process using online resources. Familiarity with the equipment and methods will boost your confidence during the interview.

3. Highlight Your Experience and Qualifications

Emphasize your relevant experience, skills, and certifications. Quantify your accomplishments with specific examples that demonstrate your ability to operate and maintain thermal cutting machines effectively.

4. Be Prepared for Technical Questions

Prepare for questions about different thermal cutting processes, such as plasma, laser, and oxy-fuel cutting. Be able to explain the advantages and disadvantages of each method and how you would select the appropriate process for a given application.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions about the company’s safety procedures, training opportunities, and advancement possibilities within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thermal Cutting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!