Are you gearing up for a career in Thermal Spray Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Thermal Spray Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

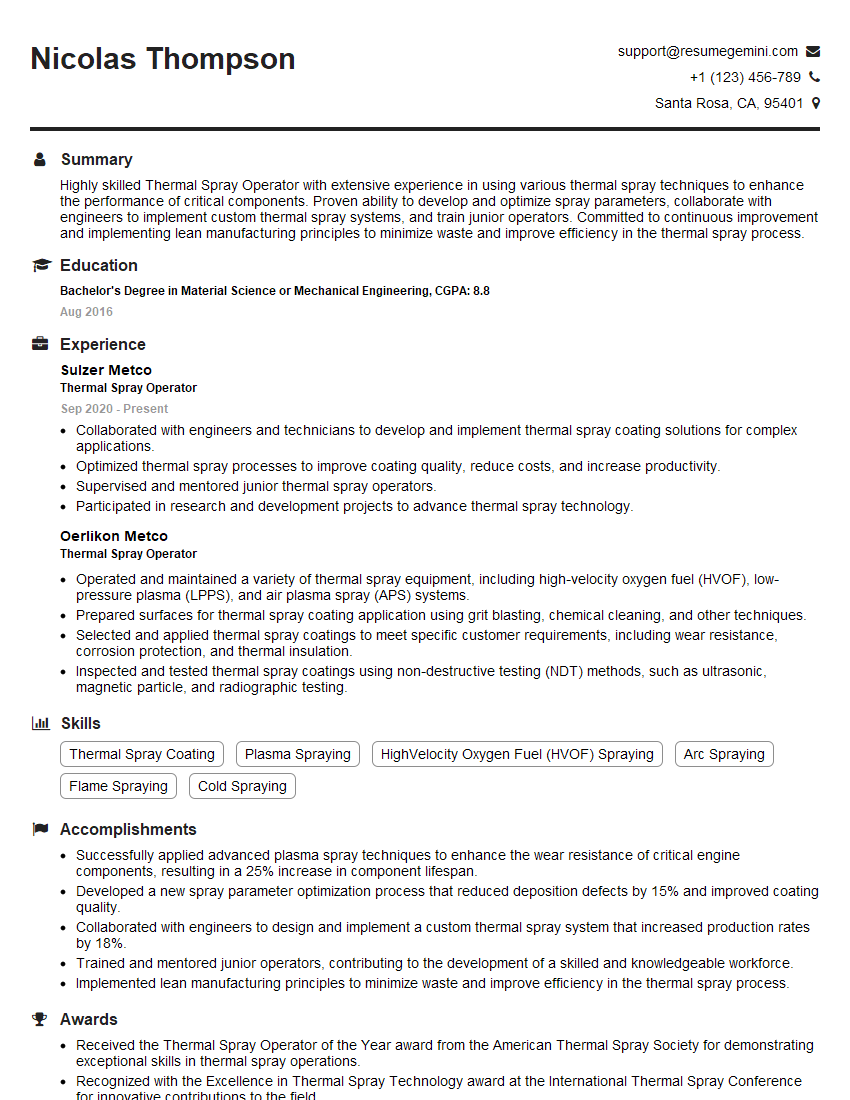

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermal Spray Operator

1. What are the different types of thermal spray processes, and what are their applications?

- Flame Spraying: Used for applying metal coatings with high bond strength and wear resistance, such as in automotive and aerospace applications.

- Plasma Spraying: Produces dense, high-quality coatings with excellent adhesion and high-temperature resistance, used in aerospace, energy, and biomedical industries.

- HVOF (High-Velocity Oxygen Fuel) Spraying: Provides coatings with high density, low porosity, and exceptional wear resistance, used in automotive, marine, and cutting tool industries.

- Cold Spraying: A solid-state process that produces coatings with high strength, low porosity, and minimal substrate heating, used in electronics, medical, and aerospace applications.

- Arc Spraying: Creates coatings with high deposition rates and good adhesion, used in construction, marine, and automotive industries.

2. What are the key factors that affect the quality of a thermal spray coating?

Substrate Preparation

- Surface cleanliness and roughness

- Substrate temperature and geometry

Spray Parameters

- Powder feed rate and particle size

- Spray distance, angle, and velocity

- Gas flow rates and types

Post-Processing

- Heat treatment

- Mechanical finishing

3. What are the common defects that can occur in thermal spray coatings, and how can they be prevented?

- Porosity: Avoid using low-quality powders, optimize spray parameters, and ensure proper substrate preparation.

- Oxidation: Use inert gases, optimize gas flow rates, and post-process coatings for oxidation resistance.

- delamination: Ensure proper surface preparation, use appropriate spray parameters, and post-process coatings to enhance adhesion.

- Cracking: Use ductile materials, optimize spray parameters to reduce residual stresses, and post-process coatings to improve toughness.

- Wear: Choose wear-resistant materials, optimize spray parameters for dense coatings, and post-process coatings to enhance surface hardness.

4. What are the safety precautions that must be taken when operating a thermal spray system?

- Wear appropriate personal protective equipment (PPE) including gloves, safety glasses, and respiratory protection.

- Ensure proper ventilation to remove fumes and gases.

- Inspect equipment regularly and maintain it in good working order.

- Follow established safety procedures and protocols.

- Be aware of potential hazards such as high temperatures, electrical hazards, and toxic materials.

5. How do you troubleshoot common problems that may arise during thermal spray operations?

- Poor Coating Adhesion: Check substrate preparation, optimize spray parameters, and inspect for contamination.

- Excessive Porosity: Use higher-quality powders, adjust spray distance and angle, and ensure proper gas flow rates.

- Coating Delamination: Verify substrate compatibility, use appropriate spray parameters, and post-process coatings to enhance adhesion.

- Powder Feed Issues: Inspect powder hopper, feed system, and gas flow rates. Adjust parameters as needed.

- Electrical Malfunctions: Check wiring, electrical connections, and grounding. Consult qualified electrician if necessary.

6. What are the different types of materials that can be used in thermal spray coatings?

- Metals: Aluminum, titanium, steel, nickel-based alloys

- Ceramics: Alumina, zirconia, tungsten carbide

- Polymers: Nylon, PTFE, polyethylene

- Composites: Ceramic-metal blends, polymer-metal blends

- Special Materials: Superalloys, biocompatible materials, corrosion-resistant materials

7. How do you determine the appropriate spray parameters for a given material and application?

- Consider the material properties, substrate characteristics, and desired coating properties (e.g., thickness, porosity, adhesion).

- Consult manufacturer’s recommendations and industry standards.

- Experiment with different parameters (e.g., powder feed rate, spray distance) to optimize coating quality.

- Use diagnostic tools to monitor coating properties and make adjustments as needed.

8. How do you ensure the quality and consistency of thermal spray coatings?

- Follow established process procedures and quality control standards.

- Perform regular equipment calibration and maintenance.

- Inspect coatings using non-destructive testing (NDT) techniques (e.g., ultrasonic, magnetic particle inspection).

- Implement statistical process control (SPC) techniques to monitor and improve process stability.

- Train and certify operators to ensure proper execution of spray procedures.

9. What are the emerging trends and advancements in thermal spray technology?

- Cold Spray: Expanding applications in aerospace, electronics, and medical industries due to its low-temperature processing capability.

- Additive Manufacturing: Thermal spray used to create complex 3D structures and repair damaged components.

- Nanostructured Coatings: Tailoring coating properties by controlling particle size and distribution at the nanoscale.

- Multi-Material Coatings: Combining different materials in a single coating to achieve desired combinations of properties (e.g., wear resistance and corrosion protection).

- Automated and Robotic Systems: Increasing efficiency and reducing operator involvement in thermal spray processes.

10. What is your understanding of the role of thermal spray coatings in the aerospace industry?

- Engine Components: Protection against wear, corrosion, and high temperatures in turbine blades, combustors, and exhaust systems.

- Airframe Structures: Enhancing corrosion resistance, reducing weight, and improving aerodynamic efficiency.

- Landing Gear: Improving wear resistance and durability of landing gear components.

- Spacecraft: Providing thermal protection, radiation shielding, and corrosion resistance in extreme space environments.

- Repair and Overhaul: Restoring damaged or worn components to extend their lifespan and reduce maintenance costs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermal Spray Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermal Spray Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thermal Spray Operators are responsible for a range of tasks related to the thermal spraying process, which involves using a heat source to apply a coating to a surface.

1. Prepare surfaces for thermal spraying

This involves cleaning the surface to remove any dirt or debris, and then roughening the surface to provide a good bond for the coating.

- Clean surfaces using solvents, detergents, or abrasives

- Roughen surfaces using sandblasting, grit blasting, or grinding

2. Select and apply thermal spray coatings

This involves choosing the right type of coating for the application, and then applying it using a thermal spray gun.

- Select coatings based on the desired properties, such as wear resistance, corrosion resistance, or thermal insulation

- Apply coatings using thermal spray guns, such as plasma spray guns, arc spray guns, or flame spray guns

3. Inspect and test thermal spray coatings

This involves checking the coating for defects and ensuring that it meets the required specifications.

- Inspect coatings for defects using visual inspection, dye penetrant testing, or ultrasonic testing

- Test coatings for adhesion, wear resistance, corrosion resistance, and other properties

4. Maintain thermal spray equipment

This involves cleaning and repairing the thermal spray equipment, and ensuring that it is operating correctly.

- Clean and lubricate thermal spray guns

- Repair and replace worn or damaged parts

- Calibrate thermal spray equipment to ensure accurate and consistent operation

Interview Tips

To prepare for an interview for a Thermal Spray Operator position, you should research the company and the position itself. You should also practice answering common interview questions. Here are some tips to help you ace the interview:

1. Research the company and the position

This will help you understand the company’s culture and goals, and the specific requirements of the position. You can research the company’s website, LinkedIn page, and Glassdoor reviews.

- Learn about the company’s history, products, and services

- Read the job description carefully and identify the key requirements

- Research the industry and the latest trends in thermal spraying

2. Practice answering common interview questions

Here are some common interview questions for Thermal Spray Operators, along with tips on how to answer them:

- Tell me about your experience with thermal spraying.

- What are the different types of thermal spray coatings?

- What are the advantages and disadvantages of thermal spraying?

- What are the challenges of thermal spraying?

In your answer, be sure to highlight your skills and experience in all aspects of thermal spraying, including surface preparation, coating selection, application, inspection, and testing.

In your answer, discuss the different types of thermal spray coatings, such as ceramic coatings, metallic coatings, and polymer coatings, and their applications.

In your answer, discuss the advantages of thermal spraying, such as its ability to apply coatings to a wide variety of materials, and its ability to create coatings with a variety of properties. Also discuss the disadvantages of thermal spraying, such as its high cost and its potential for environmental hazards.

In your answer, discuss the challenges of thermal spraying, such as the need for specialized equipment and training, and the need to control the process parameters carefully to ensure the quality of the coating.

3. Be prepared to talk about your experience and qualifications

In your interview, be prepared to talk about your experience and qualifications as they relate to the position. Be sure to highlight your skills and experience in thermal spraying, as well as your knowledge of the industry.

- Discuss your experience in all aspects of thermal spraying, including surface preparation, coating selection, application, inspection, and testing

- Highlight your knowledge of the different types of thermal spray coatings and their applications

- Emphasize your understanding of the advantages and disadvantages of thermal spraying

- Explain how you have overcome the challenges of thermal spraying in your previous roles

4. Be confident and enthusiastic

Confidence and enthusiasm are key to making a good impression in an interview. Be confident in your abilities and your knowledge, and be enthusiastic about the opportunity to work as a Thermal Spray Operator.

- Make eye contact with the interviewer and speak clearly and confidently

- Be positive and enthusiastic about the position and the company

- Show that you are eager to learn and grow in your career

Next Step:

Now that you’re armed with the knowledge of Thermal Spray Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Thermal Spray Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini