Are you gearing up for an interview for a Thermite Welder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Thermite Welder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

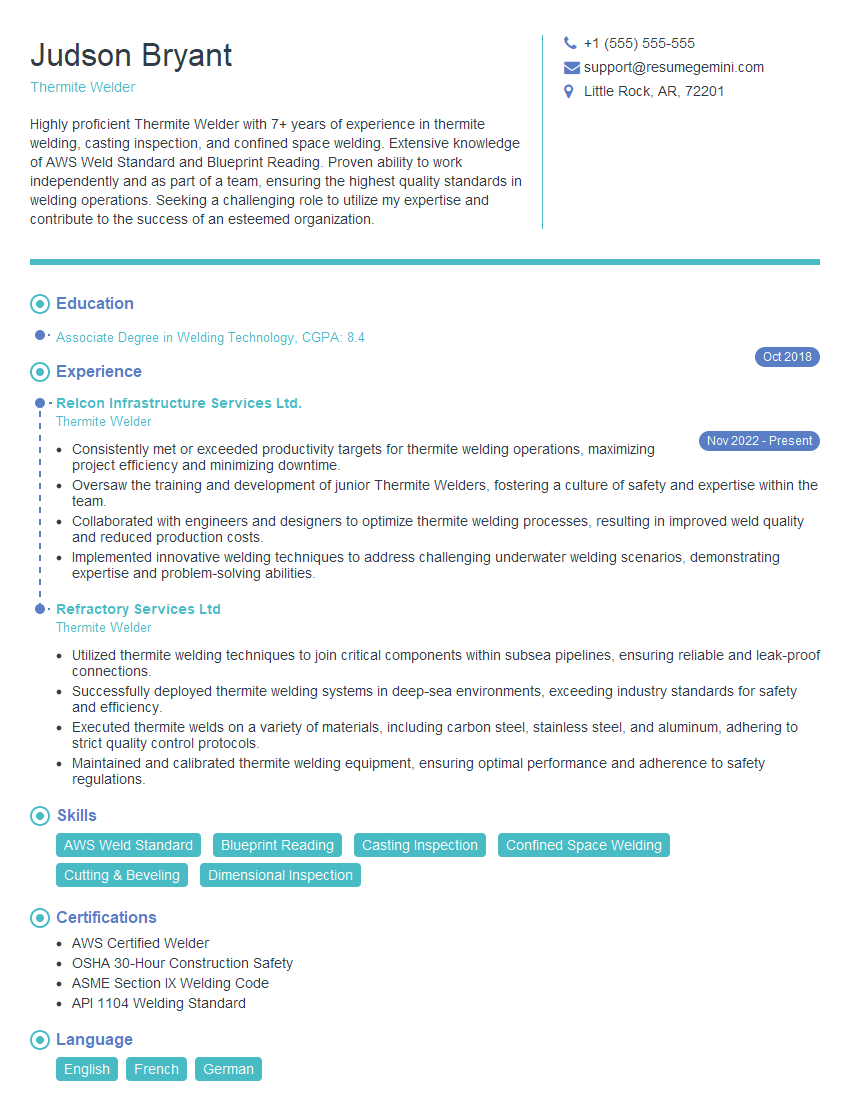

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermite Welder

1. What are the different types of thermite welding processes?

There are two main types of thermite welding processes: the open mold process and the closed mold process. In the open mold process, the molten thermite metal is poured into an open mold, which allows for faster cooling and solidification. In the closed mold process, the molten thermite metal is poured into a closed mold, which results in slower cooling and solidification.

2. What are the advantages of using thermite welding?

Advantages

- High strength and hardness of welds.

- Excellent wear and corrosion resistance.

- Ability to weld thick sections of metal.

- Portability of equipment.

3. What are the disadvantages of using thermite welding?

There are several disadvantages to using thermite welding, including:

- High cost of materials.

- Need for specialized equipment.

- Potential for fumes and sparks.

- Difficulty in controlling the weld pool.

- Need for post-weld heat treatment in some cases.

4. What are the safety precautions that must be taken when using thermite welding?

Many safety precautions must be taken when using thermite welding, including:

- Wear appropriate safety gear, including gloves, safety glasses, and a welding apron.

- Use a well-ventilated area.

- Keep flammable materials away from the welding area.

- Have a fire extinguisher nearby.

- Do not weld on or near energized electrical equipment.

5. What are the different types of thermite welding applications?

Thermite welding is used in a variety of applications, including:

- Joining railroad rails.

- Repairing castings and other metal components.

- Building up worn surfaces.

- Welding dissimilar metals.

6. How do you prepare a joint for thermite welding?

To prepare a joint for thermite welding, the following steps must be taken:

- Clean the joint surfaces.

- Bevel the joint edges.

- Assemble the joint using clamps or tack welds.

- Preheat the joint to the desired temperature.

7. How do you ignite the thermite reaction?

The thermite reaction can be ignited using a variety of methods, including:

- Using a sparkler.

- Using a magnesium ribbon.

- Using an electric arc.

- Using a friction spark.

8. How do you control the thermite weld pool?

The thermite weld pool can be controlled using a variety of methods, including:

- Using a dam or mold to contain the molten metal.

- Using a flux to control the flow of the molten metal.

- Using a welding rod to add metal to the weld pool.

- Using a torch to direct the molten metal.

9. How do you post-weld heat treat a thermite weld?

Thermite welds can be post-weld heat treated to improve their strength and toughness. The heat treatment process involves heating the weld to a specific temperature and then cooling it slowly.

10. What are the different types of thermite welding equipment?

There are a variety of thermite welding equipment available, including:

- Thermite welding torches.

- Thermite welding crucibles.

- Thermite welding molds.

- Thermite welding fluxes.

- Thermite welding accessories.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermite Welder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermite Welder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thermite Welders play a crucial role in construction and manufacturing, utilizing the thermite welding process to join metal components. Their responsibilities encompass:

1. Preparing for Thermite Welding

Thermite welders meticulously prepare the worksite and materials for successful welding.

- Ensure work area is clear of flammable materials, as thermite welding generates intense heat.

- Inspect welding equipment for optimal functionality and safety.

- Clean and prepare weld surfaces to achieve strong and durable joints.

2. Thermite Welding Execution

With precision, thermite welders execute the welding process:

- Mix thermite powder into a crucible, ensuring correct proportions for optimal combustion.

- Ignite the thermite mixture, initiating a highly exothermic reaction.

- Direct the superheated molten metal into the weld joint, forming a strong and permanent bond.

3. Post-Weld Finishing

Thermite welders complete the process with post-weld finishing:

- Remove excess slag and metal from the welded joint.

- Inspect the weld to ensure it meets specifications and safety standards.

- Grind and finish the weld to achieve the desired aesthetics and functionality.

4. Safety Compliance

Adhering to safety protocols is paramount for thermite welders:

- Wear appropriate personal protective equipment, including welding helmets, gloves, and protective clothing.

- Follow established safety guidelines and procedures to prevent accidents and injuries.

- Monitor worksite conditions and implement measures to mitigate potential hazards.

Interview Tips

To ace the thermite welder interview, candidates should prepare thoroughly and showcase their skills and qualifications. Here are some essential interview preparation tips:

1. Research the Company and Role

Demonstrate your interest and understanding of the company’s operations, industry, and specific requirements for the thermite welder position.

- Visit the company’s website to gather information on its history, products or services, and industry standing.

- Review the job description thoroughly to grasp the responsibilities, qualifications, and skills required for the role.

2. Highlight Relevant Skills and Experience

Emphasize your technical abilities and experience in thermite welding. Quantify your accomplishments whenever possible to showcase your value.

- Provide specific examples of successful thermite welding projects you have completed.

- Quantify your results, such as the number of welds completed, the thickness of materials welded, or the time it took to complete welds.

3. Prepare for Technical Questions

Expect technical questions about thermite welding. Be prepared to discuss the process, materials, and safety precautions.

- Review the fundamentals of thermite welding, including the chemical reaction, equipment used, and safety protocols.

- Practice answering questions about the advantages and disadvantages of thermite welding compared to other welding methods.

4. Emphasize Safety Consciousness

Safety is paramount in thermite welding. Demonstrate your understanding of safety precautions and your commitment to following them.

- Explain the importance of wearing appropriate personal protective equipment and maintaining a clean and safe work area.

- Describe your experience in implementing safety measures to prevent accidents and injuries on the job.

5. Practice Common Interview Questions

Prepare for general interview questions that may be asked, such as describing your strengths and weaknesses or why you are interested in the position.

- Craft concise and articulate answers that highlight your skills and qualifications.

- Practice delivering your answers confidently and professionally.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thermite Welder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!