Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Thermoplastic Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

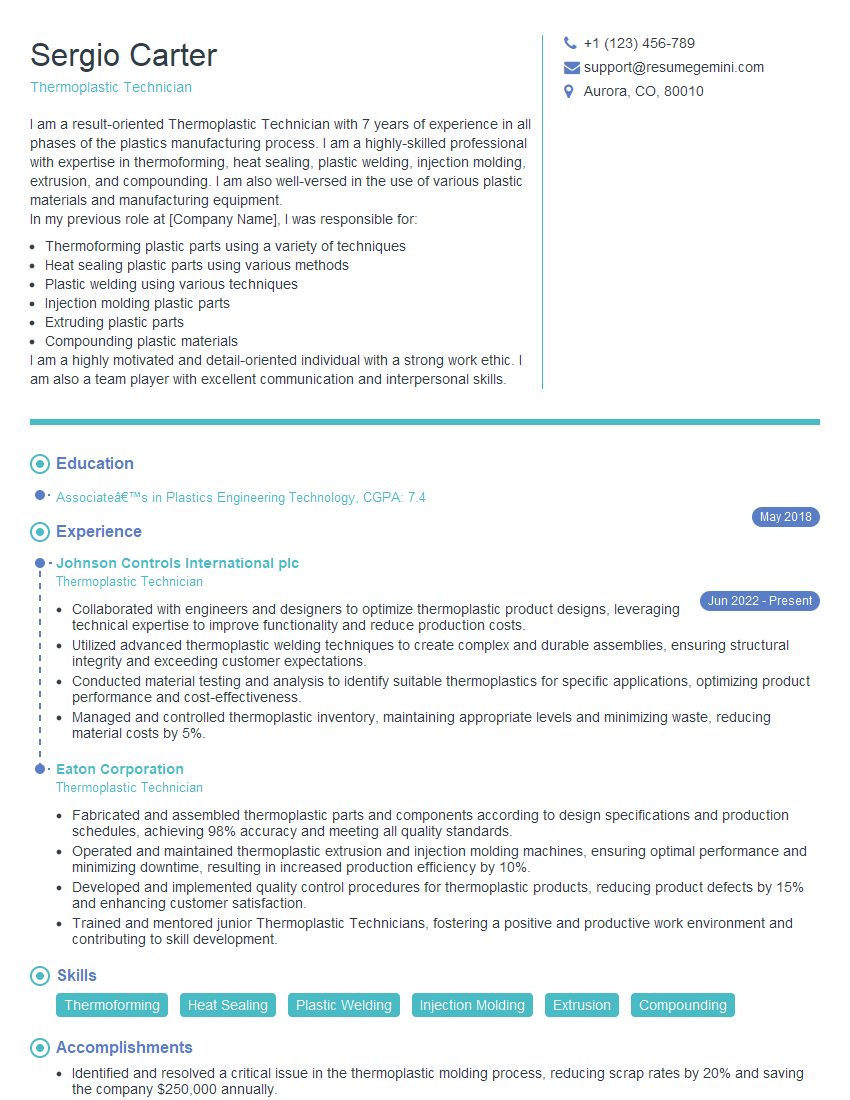

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thermoplastic Technician

1. Explain the different types of thermoplastic materials and their applications.

Answer

- Polyethylene (PE): Used in packaging, bottles, and toys

- Polypropylene (PP): Used in automotive parts, appliances, and packaging

- Polyvinyl chloride (PVC): Used in pipes, siding, and flooring

- Polystyrene (PS): Used in food containers, foam insulation, and packaging

- Polyethylene terephthalate (PET): Used in bottles, jars, and clothing fibers

2. Describe the various methods used for molding thermoplastics.

Answer

Injection Molding

- Molten plastic is injected into a mold under pressure

- Produces complex shapes with high precision

Extrusion

- Molten plastic is forced through a die to create continuous shapes

- Used to produce pipes, sheets, films, and wire insulation

Blow Molding

- Molten plastic is blown into a mold to create hollow shapes

- Used to produce bottles, toys, and automotive parts

3. Explain the importance of mold design in thermoplastic molding.

Answer

- Proper mold design ensures uniform part thickness and flow

- Reduces defects and increases production efficiency

- Mold design affects part strength, aesthetics, and cost

4. Describe the key quality control parameters for thermoplastic parts.

Answer

- Dimensional accuracy

- Surface finish

- Material properties (tensile strength, elongation at break)

- Visual defects

- Compliance with industry standards

5. Explain the role of post-processing in thermoplastic manufacturing.

Answer

- Trimming: Removing excess material from parts

- Annealing: Improving part strength and toughness

- Decorating: Applying coatings, prints, or labels

- Assembly: Joining parts to create complete products

6. Describe the different types of testing methods used for thermoplastic materials.

Answer

- Tensile testing

- Flexural testing

- Impact testing

- Thermal analysis

- Chemical resistance testing

7. Explain the importance of safety precautions in thermoplastic manufacturing.

Answer

- Protect against burns and injuries

- Minimize exposure to hazardous chemicals

- Maintain a clean and organized work environment

- Wear appropriate personal protective equipment (PPE)

8. Describe the latest advancements in thermoplastic technology.

Answer

- Biodegradable thermoplastics

- Thermoplastics with enhanced strength and toughness

- Thermoplastics with improved thermal stability

- 3D printing of thermoplastic materials

9. Explain the principles of infrared welding for thermoplastics.

Answer

- Infrared radiation melts the surfaces of thermoplastic parts

- The melted surfaces are then pressed together to form a bond

- Produces strong, leak-proof welds

10. Describe the common troubleshooting techniques for injection molding defects.

Answer

- Warpage: Adjust molding temperature, mold design, or material flow

- Voids: Increase injection pressure, adjust mold temperature, or vent the mold

- Flash: Reduce injection pressure, improve mold sealing, or modify mold design

- Surface defects: Clean the mold, adjust injection parameters, or reduce material temperature

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thermoplastic Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thermoplastic Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thermoplastic Technicians play a crucial role in the manufacturing industry, specializing in the production and handling of thermoplastic materials. Their duties involve:

1. Production and Processing

Thermoplastic Technicians are responsible for operating and maintaining various production equipment, such as extruders, molding machines, and injection molding systems. They monitor and adjust process parameters to ensure the production of high-quality thermoplastic products.

- Operate and maintain extrusion lines to produce thermoplastic sheets, pipes, and profiles.

- Set up and operate injection molding machines to create complex thermoplastic components.

- Control and monitor production parameters, including temperature, pressure, and speed.

2. Quality Control and Testing

Thermoplastic Technicians conduct quality control inspections and perform tests to ensure that thermoplastic products meet specifications. They analyze data and identify areas for improvement to enhance the quality of the final products.

- Inspect finished products for defects and adherence to quality standards.

- Conduct physical and mechanical tests, such as tensile strength, impact resistance, and dimensional accuracy.

- Analyze test results and identify potential problems or areas for process improvement.

3. Maintenance and Troubleshooting

Thermoplastic Technicians perform maintenance and troubleshooting on production equipment to prevent breakdowns and ensure optimal performance. They diagnose and repair mechanical, electrical, and hydraulic systems to keep operations running smoothly.

- Troubleshoot and repair injection molding machines, extruders, and other equipment.

- Identify and replace faulty components, such as sensors, valves, and actuators.

- Perform routine maintenance and preventive maintenance tasks to extend equipment lifespan.

4. Safety and Compliance

Thermoplastic Technicians prioritize safety in the workplace by adhering to established safety protocols and regulations. They ensure that all equipment is operated safely and that proper protective measures are in place to minimize risks.

- Follow safety regulations and wear appropriate personal protective equipment.

- Identify and mitigate potential hazards in the work environment.

- Train and supervise other employees on safety procedures and best practices.

Interview Tips

Preparing for an interview for a Thermoplastic Technician position requires a combination of technical knowledge and a strong understanding of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends. Research the latest developments in thermoplastic technology and applications. This knowledge will demonstrate your enthusiasm for the field and your interest in the specific role.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining thermoplastic production equipment. Describe your experience with quality control techniques and troubleshooting procedures. Quantify your accomplishments whenever possible to showcase your contributions.

3. Showcase Your Problem-Solving Abilities

Provide examples of how you have successfully resolved technical issues or improved production processes. Discuss your analytical approach and the steps you took to identify and implement solutions.

4. Emphasize Your Safety Commitment

Demonstrate your understanding of safety regulations and your ability to create a safe work environment. Highlight any safety initiatives or certifications you have obtained.

- Describe your experience with conducting safety inspections and implementing preventive measures.

- Explain how you prioritize safety in your daily work and ensure compliance with all safety protocols.

5. Prepare Questions

Asking thoughtful questions demonstrates your interest and engagement in the interview. Prepare questions related to the company’s current projects, future plans, or the role’s specific responsibilities. This also gives you an opportunity to clarify any aspects of the job description or company culture.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thermoplastic Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.