Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Thickener Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Thickener Operator so you can tailor your answers to impress potential employers.

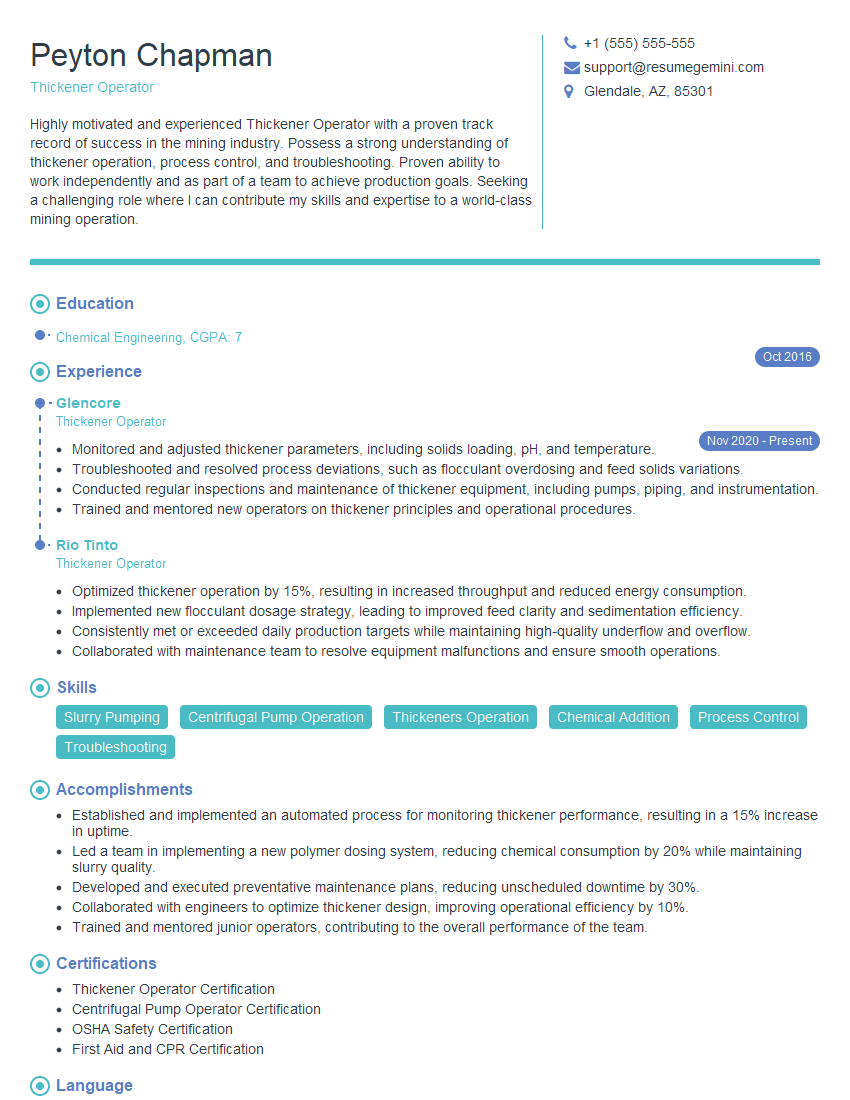

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thickener Operator

1. How do you monitor the performance of a thickener?

To monitor the performance of a thickener, I pay attention to several key factors:

- Solids content of the feed and underflow: This indicates the effectiveness of the thickening process.

- Clarified water quality: The clarity of the supernatant liquid indicates the efficiency of the settling process.

- Flocculant dosage: The amount of flocculant added affects the settling rate of solids.

- Slurry density: The density of the slurry affects the settling rate and the solids content of the underflow.

- Equipment condition: Regular inspection of the thickener, including the rakes, drive mechanism, and feedwells, ensures optimal performance.

2. What are the common operating problems associated with thickeners?

Process-Related Problems:

- Poor settling: Caused by insufficient flocculation, high solids loading, or inadequate rake speed.

- Thickener bridging: Occurs when solids accumulate on the thickener arms, hindering settling.

- Slurry dilution: Improper feed distribution or excessive water addition can dilute the slurry.

Mechanical Problems:

- Rake failure: Broken or worn rakes can disrupt the settling process.

- Drive system issues: Faulty motors or gearboxes can affect rake rotation and slurry movement.

- Leakage: Worn seals or damaged components can lead to slurry leaks.

3. How do you handle thickener upsets?

When a thickener experiences an upset, I follow a systematic approach to identify and address the issue:

- Assess the situation: Monitor key parameters and inspect the equipment for any abnormalities.

- Identify potential causes: Consider process conditions, equipment issues, or external factors.

- Implement corrective actions: Adjust flocculant dosage, modify feed rate, or perform maintenance as necessary.

- Monitor and evaluate: Closely observe the thickener’s performance after implementing corrective actions.

- Document and report: Record the upset, its cause, and the actions taken to resolve it.

4. How do you optimize thickener performance?

To optimize thickener performance, I focus on the following aspects:

- Flocculant selection and dosage: Choosing the right flocculant and optimizing its dosage improves particle settling.

- Feed distribution: Ensuring even distribution of feed slurry avoids overloading and promotes uniform settling.

- Rake speed and torque: Adjusting rake speed and torque balances particle settling and solids removal.

- Slurry density control: Maintaining an optimal slurry density enhances settling efficiency.

- Regular maintenance and inspections: Preventive maintenance and timely repairs minimize equipment downtime and improve overall performance.

5. Explain the role of flocculants in a thickening process.

Flocculants play a crucial role in the thickening process by:

- Particle bridging: Flocculants promote the formation of inter-particle bridges, creating larger flocs.

- Settling rate enhancement: Larger flocs have a higher settling velocity, reducing the time required for solids to settle.

- Slurry stabilization: Flocculants help stabilize the slurry, preventing the redispersion of settled solids.

- Reduced water content: Enhanced settling results in a thicker underflow with reduced water content.

6. Describe the different types of thickeners used in mineral processing.

- High-rate thickeners: Designed for high throughput and rapid settling, used in applications with high solids concentration.

- Conventional thickeners: Slower settling rate than high-rate thickeners, suitable for a wide range of applications.

- Deep-cone thickeners: Compact design with a deep cone-shaped bottom, providing increased settling capacity.

- Clari-thickeners: Combine the features of a thickener and a clarifier, producing both a thickened sludge and clarified water.

- Gravity thickeners: Rely on gravity to settle solids, suitable for applications with low solids concentration.

7. How do you troubleshoot a thickener that is producing cloudy overflow?

- Check flocculant dosage: Insufficient flocculant can result in poor particle settling and cloudy overflow.

- Inspect feed distribution: Uneven feed distribution can overload certain areas of the thickener, causing solids carryover.

- Examine feed solids content: High solids content in the feed can overwhelm the thickener’s capacity.

- Check rake operation: Faulty rakes can hinder solids settling and lead to cloudy overflow.

- Inspect underflow density: Too low underflow density can indicate poor settling efficiency.

8. What is the importance of rake torque monitoring in a thickener?

- Overload detection: High rake torque indicates excessive solids loading, potential rake damage, or thickener bridging.

- Underload detection: Low rake torque can indicate insufficient solids loading or improper rake operation.

- Rake wear monitoring: Gradual changes in rake torque can indicate progressive rake wear, allowing for timely maintenance.

- Process optimization: Monitoring rake torque helps optimize the thickener’s performance by adjusting rake speed and flocculant dosage.

9. Describe the safety precautions you observe when working with thickeners.

- Confined space awareness: Thickeners are often enclosed spaces, requiring proper ventilation and confined space entry procedures.

- Moving machinery hazards: Be aware of rotating rakes and other moving parts, maintaining a safe distance.

- Chemical handling: Flocculants and other chemicals used in thickeners must be handled safely and according to MSDS guidelines.

- Slurry hazards: Thickener slurries can be corrosive or hazardous, requiring appropriate protective equipment.

- Electrical hazards: Ensure proper electrical grounding and lockout/tagout procedures before performing maintenance.

10. How do you stay up-to-date with the latest developments in thickening technology?

- Industry conferences and seminars: Attend industry events to learn about new technologies and best practices.

- Technical publications: Read industry magazines, journals, and research papers to stay informed about advancements.

- Equipment supplier webinars: Participate in webinars hosted by equipment manufacturers to gain insights into their latest offerings.

- Online forums and discussion groups: Engage in online discussions with other professionals to share knowledge and learn from their experiences.

- Continuing education: Pursue relevant courses or certifications to enhance your technical skills and knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thickener Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thickener Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thickener Operators play a crucial role in mineral processing and wastewater treatment plants. Their primary duties involve operating and maintaining thickeners, which are essential for separating solids from liquids.

1. Thickener Operation

Operate and monitor thickeners to achieve optimal separation efficiency by controlling flow rates, feed concentrations, and chemical dosages.

- Adjust operating parameters to maintain desired underflow and overflow characteristics.

- Monitor and troubleshoot thickener performance, identifying and resolving any operational issues.

2. Equipment Maintenance

Perform routine maintenance and repairs on thickeners and associated equipment, ensuring their reliable operation.

- Inspect and clean thickeners, pumps, and piping systems to maintain optimal performance.

- Identify and replace worn or damaged parts to prevent breakdowns and ensure safety.

3. Process Monitoring

Monitor and control process parameters to optimize thickener performance and ensure adherence to environmental regulations.

- Monitor feed and product streams for quality, consistency, and compliance.

- Adjust process variables to meet target specifications and minimize environmental impact.

4. Safety and Compliance

Follow safety protocols and maintain a clean and safe work environment.

- Operate thickeners in compliance with established safety procedures and industry regulations.

- Wear appropriate personal protective equipment and adhere to lockout/tagout procedures.

Interview Tips

To ace the interview for a Thickener Operator position, meticulous preparation is key. Here are some tips to help you shine:

1. Research the Company and Position

Thoroughly research the company’s industry, operations, and the specific role of the Thickener Operator.

- Review the job description and identify the essential skills and qualifications.

- Learn about the company’s processes, products, and commitment to safety and environmental stewardship.

2. Highlight Your Technical Expertise

Showcase your knowledge of thickener operation, maintenance, and process control.

- Provide specific examples of how you have optimized thickener performance and resolved operational issues.

- Discuss your experience with various thickener types and equipment, including pumps, valves, and control systems.

3. Emphasize Safety and Compliance

Stress your commitment to safety and compliance with industry regulations.

- Describe your adherence to safety protocols and lockout/tagout procedures.

- Explain your understanding of environmental regulations and how you have implemented measures to minimize environmental impact.

4. Prepare for Behavioral Questions

Prepare for behavioral questions that assess your teamwork, problem-solving, and communication skills.

- Use the STAR method (Situation, Task, Action, Result) to provide structured and compelling answers.

- Highlight your ability to work effectively in a team environment and your proactive approach to resolving challenges.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Thickener Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.