Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Thiokol Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

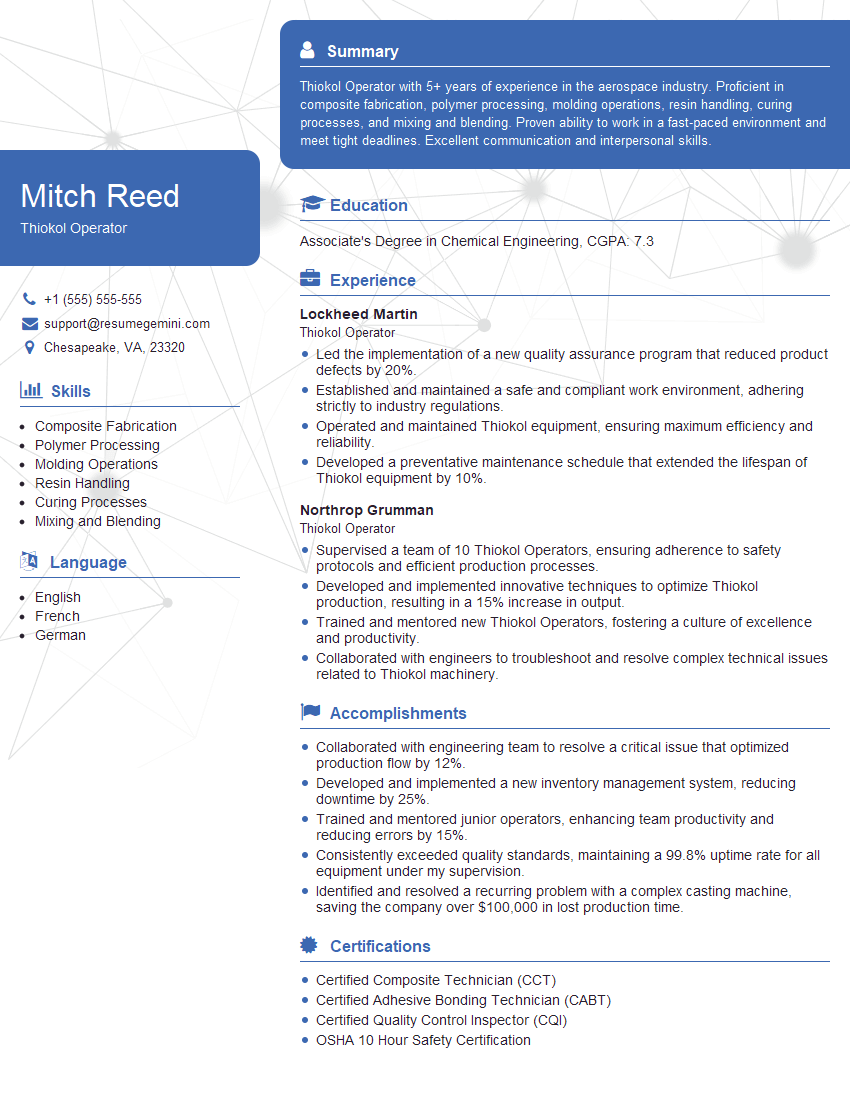

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thiokol Operator

1. What are the key responsibilities of a Thiokol Operator?

As a Thiokol Operator, my key responsibilities would include:

- Operating and monitoring Thiokol equipment, including mixers, extruders, and curing ovens

- Maintaining equipment and ensuring that it is in good working order

- Following established procedures and safety protocols

- Inspecting and testing raw materials and finished products

- Working with other team members to ensure efficient production

2. What are the different types of Thiokol products that you have experience working with?

I have experience working with a variety of Thiokol products, including:

Solid Propellants

- TP-H1100

- TP-H1200

- TP-H1300

Liquid Propellants

- LP-2

- LP-3

- LP-4

Polymers and Composites

- ST-100

- ST-200

- ST-300

3. What are the safety protocols that you must follow when working with Thiokol products?

When working with Thiokol products, I must follow a number of safety protocols, including:

- Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a respirator

- Working in a well-ventilated area

- Following established procedures for handling and storing Thiokol products

- Being aware of the potential hazards of Thiokol products and taking steps to minimize the risk of accidents

4. What are the quality control procedures that you follow when working with Thiokol products?

When working with Thiokol products, I follow a number of quality control procedures, including:

- Inspecting raw materials and finished products to ensure that they meet specifications

- Conducting tests to verify the performance of Thiokol products

- Maintaining records of all quality control activities

5. What are the troubleshooting steps that you would take if you encountered a problem with a Thiokol product?

If I encountered a problem with a Thiokol product, I would take the following troubleshooting steps:

- Identify the problem and its symptoms

- Review the operating procedures and safety protocols

- Inspect the equipment and materials

- Consult with a supervisor or other qualified personnel

- Take corrective action to resolve the problem

6. What are the key safety considerations when working with solid propellants?

When working with solid propellants, the key safety considerations include:

- Solid propellants are highly energetic materials that can be ignited by heat, impact, or friction

- Solid propellants produce toxic gases when ignited, so it is important to work in a well-ventilated area

- Solid propellants can be explosive, so it is important to follow established procedures for handling and storing them

- Solid propellants can be sensitive to electrostatic discharge, so it is important to use proper grounding and bonding techniques

7. What are the different types of solid propellant motors?

There are two main types of solid propellant motors:

Boosters

- Boosters are used to provide the initial thrust for a rocket launch

- Boosters are typically large and powerful motors that burn for a short period of time

Sustainers

- Sustainers are used to provide the main thrust for a rocket once it has left the atmosphere

- Sustainers are typically smaller and less powerful than boosters, but they burn for a longer period of time

8. What are the different types of liquid propellants?

There are two main types of liquid propellants:

Monopropellants

- Monopropellants are propellants that contain both fuel and oxidizer in a single component

- Monopropellants are typically used in small rockets and thrusters

Bipropellants

- Bipropellants are propellants that contain separate fuel and oxidizer components

- Bipropellants are typically used in larger rockets and engines

9. What are the different types of polymers and composites used in rocketry?

There are a variety of polymers and composites used in rocketry, including:

- Carbon-fiber reinforced polymers (CFRPs)

- Glass-fiber reinforced polymers (GFRPs)

- Kevlar

- Nomex

10. What are the key factors that affect the performance of a rocket motor?

The performance of a rocket motor is affected by a number of factors, including:

- The type of propellant used

- The size and shape of the motor

- The nozzle design

- The operating conditions

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thiokol Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thiokol Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thiokol Operators play a crucial role in the production of solid rocket propellants. Their key responsibilities encompass:

1. Mixing and Compounding

Preparing and mixing raw materials such as polymers, oxidizers, and additives to create the desired propellant composition.

2. Loading and Curing

Loading mixed propellants into molds, applying pressure, and curing them to achieve the required shape and properties.

3. Quality Control

Conducting quality control tests on raw materials and finished propellants to ensure compliance with specifications and safety standards.

4. Equipment Operation and Maintenance

Operating and maintaining specialized equipment used in the production process, including mixers, molds, and curing ovens.

5. Safety Compliance

Adhering to all safety protocols and regulations, including wearing protective gear, handling hazardous materials, and responding to emergencies.

Interview Tips

To ace an interview for a Thiokol Operator role, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s profile, products, and industry trends. This demonstrates your interest and preparation.

2. Highlight Relevant Experience and Skills

Emphasize previous experience in handling hazardous materials, operating heavy machinery, and maintaining safety standards.

3. Quantify Your Accomplishments

Provide specific examples and metrics to quantify your contributions in previous roles. For instance, discuss how your efforts improved production efficiency or reduced defects.

4. Prepare for Technical Questions

Be prepared to discuss technical aspects of propellant production, including mixing techniques, curing processes, and quality control procedures.

5. Show Enthusiasm and Passion

Convey your genuine interest in the field and demonstrate your eagerness to contribute to the company’s success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thiokol Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!