Feeling lost in a sea of interview questions? Landed that dream interview for Thread Checker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Thread Checker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

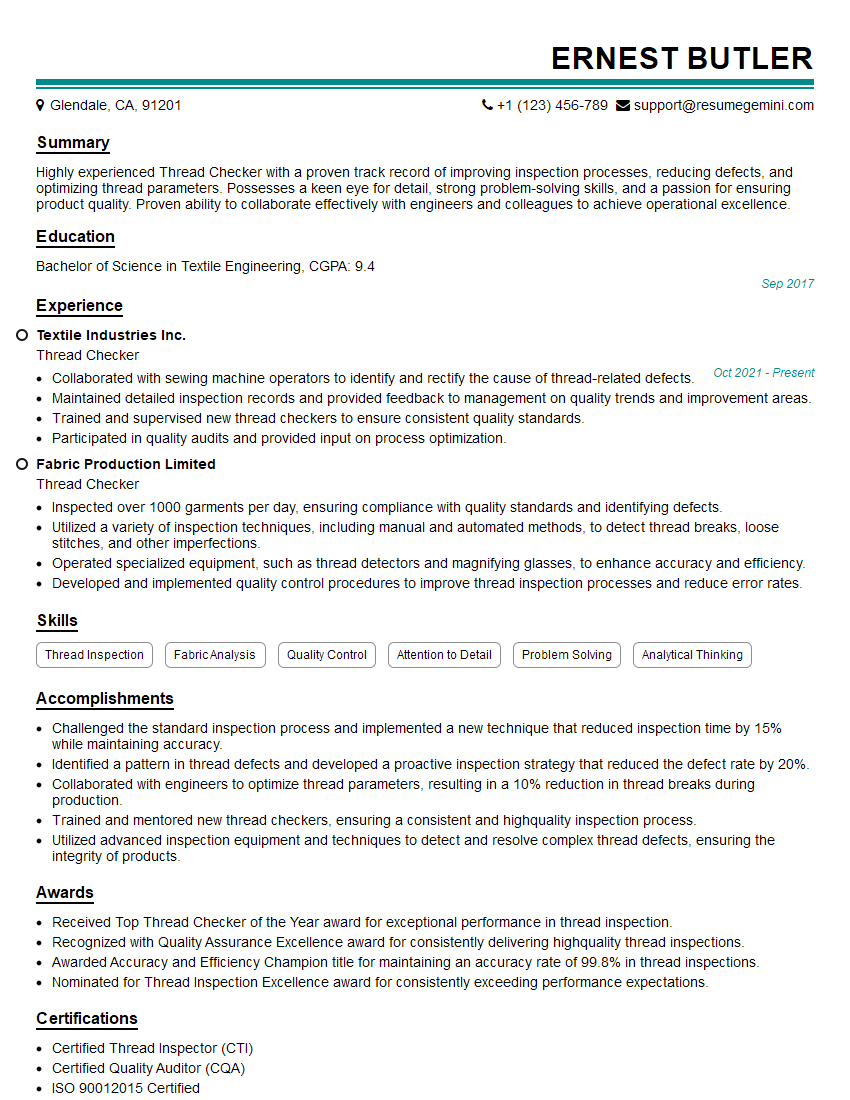

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thread Checker

1. Explain the key responsibilities of a Thread Checker in the apparel industry.

As a Thread Checker in the apparel industry, I play a vital role in ensuring the quality of garments produced. My responsibilities encompass:

- Inspecting garments for defects in stitching, fabric, and construction

- Identifying and marking any deviations from established quality standards

- Maintaining detailed records of all inspections and defects found

- Working closely with production teams to identify and resolve quality issues

- Training and supervising other thread checkers to maintain consistent quality standards

2. What are the different types of thread defects that you typically encounter in your work?

During my work as a Thread Checker, I encounter various types of thread defects, including:

Broken/Missing Threads

- Threads that are snapped or missing from the seam

- Can lead to seam failure and fabric tearing

Skipped Stitches

- Stitches that are not formed correctly, resulting in gaps in the seam

- Can weaken the durability of the garment

Loose Stitches

- Stitches that are not tight enough, allowing the fabric to move freely

- Can cause the seam to unravel and lead to fabric distortion

3. Describe the process you follow when inspecting a garment for thread defects.

To ensure thorough and accurate inspections, I adhere to the following process:

- Visual Examination: I visually inspect each garment, scanning for any visible defects in stitching, fabric, and construction.

- Manual Examination: I gently run my fingers along the seams to feel for any broken, skipped, or loose stitches.

- Magnification Tools: I use magnifying glasses or microscopes to examine intricate details and identify defects that may not be visible to the naked eye.

- Marking Defects: I mark all identified defects using colored threads or chalk, ensuring that they can be easily identified by production teams.

4. How do you prioritize and classify thread defects based on their severity?

To ensure that critical defects are addressed promptly, I prioritize and classify them based on their potential impact on the garment’s quality and durability:

- Major Defects: These defects significantly compromise the garment’s integrity, such as broken seams or large fabric tears.

- Minor Defects: While less critical, these defects can still affect the garment’s appearance or functionality, such as skipped stitches or loose threads.

- Cosmetic Defects: These defects affect the garment’s aesthetic appeal but do not impact its overall functionality, such as slight color variations.

5. What tools and techniques do you use to identify thread defects that may not be immediately visible?

Beyond visual and manual inspections, I employ various tools and techniques to detect hidden thread defects:

- Thread Tension Gauge: I use a thread tension gauge to measure the tension of threads in the seams, ensuring that they are not too tight or too loose.

- Bursting Strength Tester: I use a bursting strength tester to assess the strength of the garment’s seams, ensuring that they can withstand normal wear and tear.

- Fabric Analysis: I analyze the fabric’s weave and composition to determine the appropriate thread size and type for the garment.

6. How do you stay updated with the latest industry standards and best practices for thread checking?

To maintain the highest quality standards, I continuously seek opportunities to enhance my knowledge:

- Industry Publications and Journals: I subscribe to industry publications and journals to stay abreast of best practices and innovations in thread checking.

- Workshops and Conferences: I attend workshops and conferences to learn from other industry professionals and share knowledge.

- Online Resources: I utilize online resources, such as webinars and forums, to access up-to-date information and connect with experts.

7. Describe a situation where you identified a recurring thread defect and implemented a solution to prevent its recurrence.

In my previous role, I encountered a recurring issue with skipped stitches in a particular seam. Through thorough investigation, I discovered that the issue was caused by a misalignment of the sewing machine’s needles. By working with the production team, I implemented a solution to adjust the needle alignment, which effectively eliminated the skipped stitch defect.

8. How do you handle disagreements with production personnel regarding the severity of thread defects?

In situations where disagreements arise, I approach the discussion professionally and objectively:

- Communicate Clearly: I clearly articulate my reasons for classifying a defect as a particular severity, providing specific examples and evidence.

- Active Listening: I actively listen to the production personnel’s perspective and try to understand their reasoning.

- Find Common Ground: I work towards finding common ground and reaching a mutually acceptable solution that maintains quality standards.

9. How do you cope with the pressure of working in a fast-paced environment while maintaining accuracy in your inspections?

I thrive in fast-paced environments by:

- Time Management: I effectively manage my time to ensure that I can inspect garments thoroughly while meeting deadlines.

- Prioritization: I prioritize tasks based on their severity and potential impact, focusing on critical defects first.

- Accuracy Mindset: I maintain a strong focus on accuracy, never compromising quality for speed.

10. What are your career goals and aspirations as a Thread Checker?

As a dedicated Thread Checker, my career aspirations include:

- Quality Assurance Manager: I aim to progress into a Quality Assurance Manager role, where I can oversee the implementation and maintenance of quality standards throughout the production process.

- Technical Trainer: I am passionate about sharing my knowledge and expertise. I aspire to become a technical trainer, guiding new thread checkers and contributing to the development of highly skilled professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thread Checker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thread Checker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thread checkers play a vital role in ensuring the quality of textiles and garments by inspecting and verifying the consistency, strength, and appearance of threads.

1. Thread Inspection and Analysis

Inspect and analyze threads using various techniques such as visual checks, microscopy, and tensile testing.

- Identify and report defects, such as knots, breaks, unevenness, or discoloration.

- Evaluate thread quality against established standards and specifications.

2. Consistency Maintenance

Maintain thread consistency throughout the production process.

- Monitor thread tension, twist levels, and other parameters.

- Calibrate and adjust equipment to ensure optimal thread quality.

3. Problem Investigation and Resolution

Investigate and resolve thread-related problems that arise during production.

- Analyze data, conduct tests, and identify root causes of thread defects.

- Develop and implement corrective actions to prevent recurrence.

4. Documentation and Reporting

Document and report thread inspection results, defects identified, and corrective actions taken.

- Maintain detailed records for quality control purposes.

- Provide regular reports to management and stakeholders.

Interview Tips

To ace the Thread Checker interview, candidates should prepare thoroughly and demonstrate their understanding of the job responsibilities and industry knowledge.

1. Research the Company and Role

Before the interview, research the company’s website, products, and mission.

- Identify the specific responsibilities and expectations for the Thread Checker role.

- Prepare questions that demonstrate your interest in the company and the position.

2. Technical Knowledge

Highlight your technical knowledge in thread inspection methods and quality control principles.

- Be prepared to discuss your experience in using industry-standard equipment and software.

- Explain how you ensure accuracy and reliability in your inspections.

3. Problem-Solving Skills

Showcase your problem-solving abilities and critical thinking skills.

- Describe how you approach and investigate thread-related problems.

- Provide examples of successful corrective actions you have implemented.

4. Communication and Teamwork

Emphasize your strong communication and teamwork skills.

- Explain how you communicate effectively with colleagues, supervisors, and customers.

- Discuss your experience working collaboratively in a team environment.

5. Enthusiasm and Passion

Convey your enthusiasm and passion for quality control and thread inspection.

- Explain why you are interested in this role and industry.

- Share your commitment to ensuring textile and garment quality.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Thread Checker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!