Are you gearing up for an interview for a Thread Milling Machine Set Up Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Thread Milling Machine Set Up Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

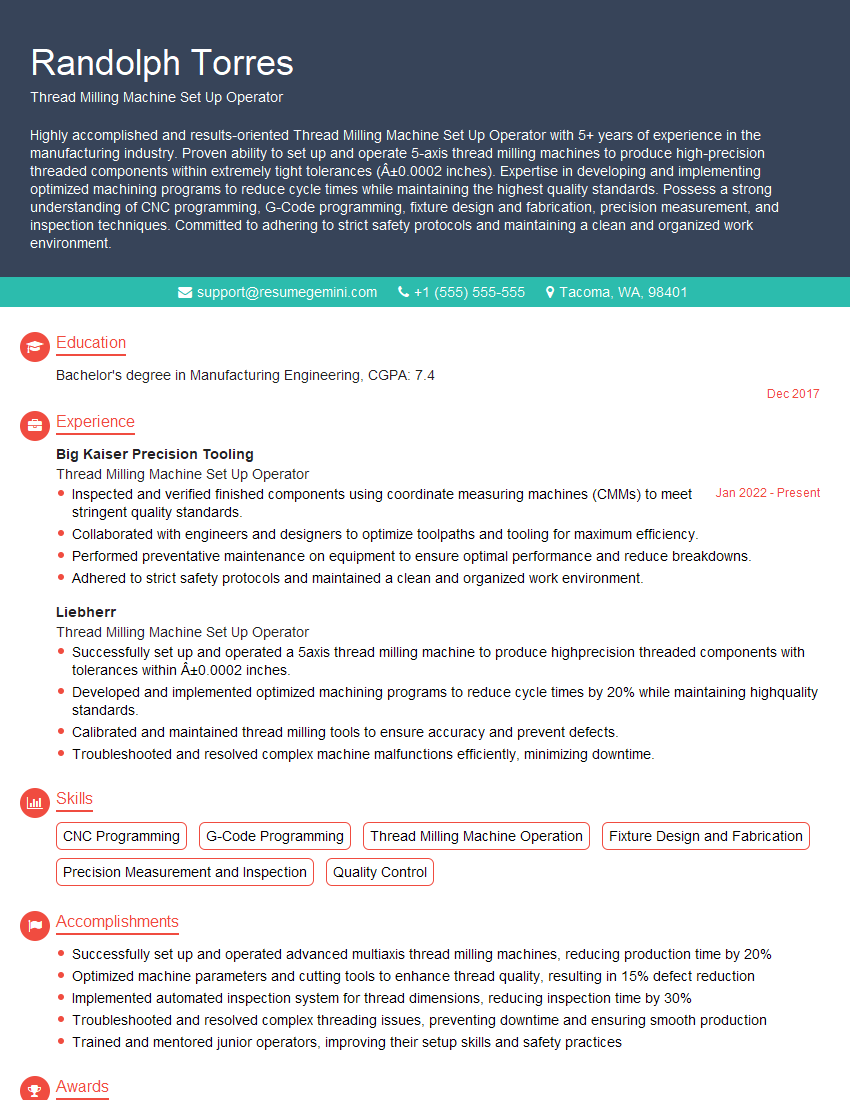

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Thread Milling Machine Set Up Operator

1. What are the key steps involved in setting up a thread milling machine?

The key steps involved in setting up a thread milling machine include:

- Installing the workpiece and securing it properly.

- Selecting the appropriate cutting tool and mounting it in the tool holder.

- Setting the machine parameters, such as spindle speed, feedrate, and thread pitch.

- Running a test cut to verify the settings and make any necessary adjustments.

2. What are the different types of thread milling cutters?

Types of Thread Milling Cutters:

- Single-point cutters

- Multi-point cutters

Single-Point Cutters:

- Used for high-precision threading

- Require skilled operators

Multi-Point Cutters:

- Can produce threads in a single pass

- Faster and more efficient than single-point cutters

- Less skilled operators required

3. What are the factors that affect the quality of a thread milled surface?

The factors that affect the quality of a thread milled surface include:

- The sharpness of the cutting tool

- The feedrate and spindle speed

- The workpiece material

- The depth of cut

- The machine’s rigidity

4. What are the common problems that can occur during thread milling?

The common problems that can occur during thread milling include:

- Chatter

- Tool breakage

- Oversized or undersized threads

- Tapered threads

- Thread galling

5. What are the safety precautions that should be taken when operating a thread milling machine?

The safety precautions that should be taken when operating a thread milling machine include:

- Wearing appropriate safety gear, such as eye protection, earplugs, and gloves.

- Keeping the work area clean and free of debris.

- Ensuring that the machine is properly grounded.

- Never reaching into the machine while it is running.

- Following the manufacturer’s instructions for safe operation.

6. What are the different types of coolants used in thread milling?

The different types of coolants used in thread milling include:

- Soluble oil

- Semi-synthetic coolant

- Synthetic coolant

- Cryogenic coolant

7. What are the advantages of using a CNC thread milling machine?

The advantages of using a CNC thread milling machine include:

- Increased accuracy and precision

- Reduced setup time

- Increased productivity

- Improved surface finish

- Reduced operator error

8. What are the different types of thread milling operations?

The different types of thread milling operations include:

- External thread milling

- Internal thread milling

- Tapered thread milling

- Multi-start thread milling

9. What are the key factors to consider when selecting a thread milling machine?

The key factors to consider when selecting a thread milling machine include:

- The size and shape of the workpieces to be machined

- The required accuracy and precision

- The desired production rate

- The available budget

10. What are the latest trends in thread milling technology?

The latest trends in thread milling technology include:

- The development of new cutting tool materials

- The use of advanced CNC controls

- The integration of automation and robotics

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Thread Milling Machine Set Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Thread Milling Machine Set Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Thread Milling Machine Set Up Operators play a vital role in optimizing production processes and ensuring the precision of threaded parts. Their key responsibilities include:

1. Machine Setup and Configuration

Setting up and configuring thread milling machines according to production requirements and blueprints.

- Mounting and aligning cutting tools, fixtures, and workpieces.

- Programming and optimizing machine parameters, such as spindle speed, feed rate, and depth of cut.

2. Operation and Monitoring

Operating thread milling machines efficiently and safely to produce high-quality parts.

- Monitoring machine performance, adjusting parameters as needed.

- Performing quality control checks and inspecting finished parts.

3. Maintenance and Troubleshooting

Maintaining and troubleshooting thread milling machines to ensure optimal performance.

- Performing routine inspections and preventive maintenance.

- Identifying and resolving machine malfunctions, replacing parts as necessary.

4. Collaboration and Communication

Collaborating with production teams, engineers, and quality control personnel.

- Communicating machine performance, maintenance issues, and troubleshooting results.

- Providing support and assisting in developing process improvements.

Interview Tips

To prepare for a Thread Milling Machine Set Up Operator interview, it is essential to:

1. Research the Company and Role

Gather information about the company’s industry, products, and specific requirements for the role.

- Identify the company’s mission, values, and goals.

- Research the specific responsibilities and expectations of the Thread Milling Machine Set Up Operator position.

2. Practice Common Interview Questions

Prepare for common interview questions related to machine operation, maintenance, troubleshooting, and quality control.

- Review questions about your experience with thread milling machines, programming, and maintenance.

- Practice answering questions about your problem-solving and troubleshooting abilities.

3. Highlight Relevant Experience

Emphasize your hands-on experience with thread milling machines, CNC programming, and maintenance.

- Provide specific examples of projects or tasks where you demonstrated your skills.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your work.

4. Demonstrate Safety Awareness

Highlight your understanding of safety protocols and your commitment to operating machinery safely.

- Explain your knowledge of machine safety features and procedures.

- Provide examples of how you have implemented safety measures in your previous roles.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Thread Milling Machine Set Up Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.