Feeling lost in a sea of interview questions? Landed that dream interview for Threading Machine Setter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Threading Machine Setter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

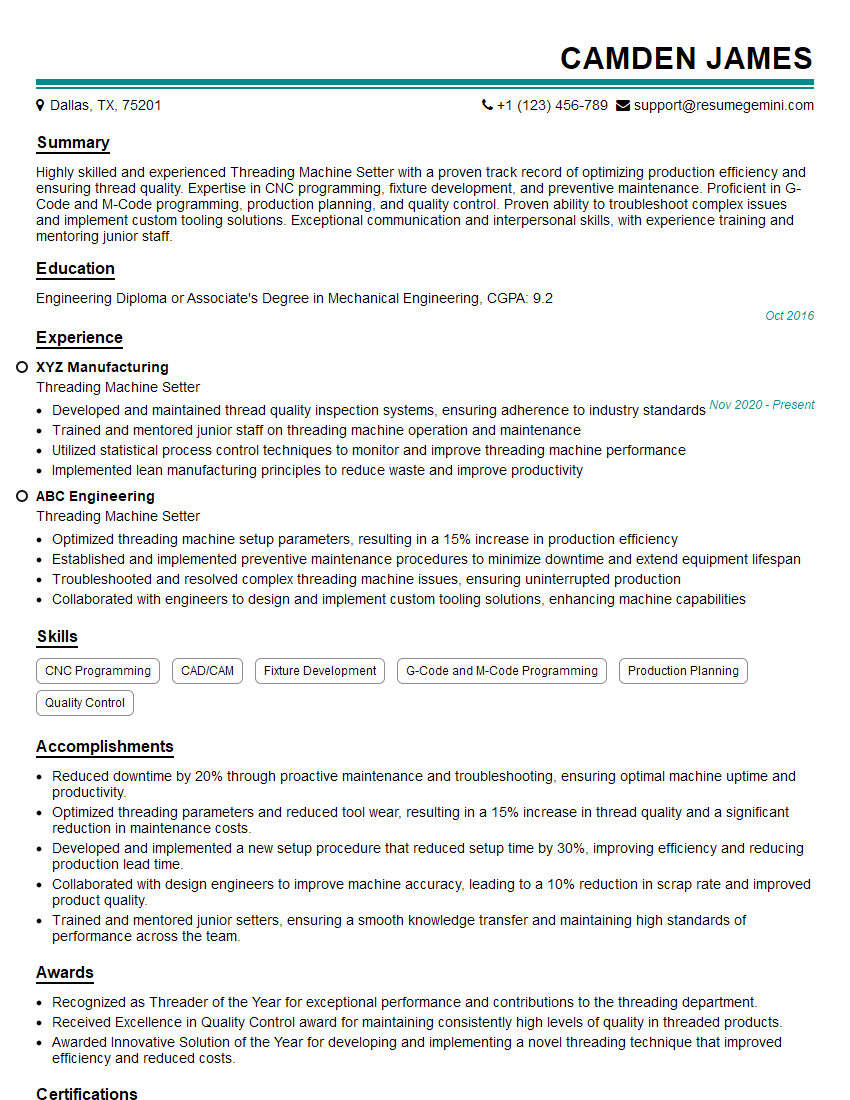

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Threading Machine Setter

1. What are the major responsibilities of a Threading Machine Setter?

- Set up and operate threading machines to cut external or internal threads on metal workpieces.

- Measure and inspect threaded parts to ensure they meet specifications.

- Adjust and maintain threading machines to ensure optimal performance.

- Troubleshoot and resolve problems with threading machines and threaded parts.

- Maintain a clean and organized work area.

2. What are the key skills required for a Threading Machine Setter?

Technical Skills

- Proficient in operating threading machines.

- Knowledge of threading processes and techniques.

- Ability to read and interpret blueprints and technical drawings.

- Strong understanding of metrology and measurement techniques.

- Experience with troubleshooting and repairing threading machines.

Soft Skills

- Excellent attention to detail.

- Strong problem-solving skills.

- Ability to work independently and as part of a team.

- Excellent communication and interpersonal skills.

3. What are the different types of threading machines?

- Manual threading machines.

- Semi-automatic threading machines.

- CNC threading machines.

- Roll threading machines.

- Tapping machines.

4. What are the different types of threads?

- External threads.

- Internal threads.

- Tapered threads.

- Straight threads.

- Left-hand threads.

- Right-hand threads.

5. What are the factors that affect the quality of threaded parts?

- Material of the workpiece.

- Type of threading machine.

- Threading tool.

- Threading process parameters.

- Inspection and measurement techniques.

6. What are the common problems encountered in threading operations?

- Burrs and sharp edges.

- Cross-threading.

- Undercutting.

- Overcutting.

- Thread galling.

7. How do you troubleshoot and resolve threading problems?

- Identify the problem.

- Determine the cause of the problem.

- Implement a solution to fix the problem.

- Test the solution to ensure it is effective.

8. What are the safety precautions that must be observed when operating threading machines?

- Wear appropriate safety gear.

- Keep hands and loose clothing away from moving parts.

- Securely clamp the workpiece.

- Use sharp threading tools.

- Follow proper threading procedures.

9. What are the maintenance procedures for threading machines?

- Clean and lubricate the machine regularly.

- Inspect the machine for wear and tear.

- Calibrate the machine regularly.

- Replace worn or damaged parts.

- Store the machine in a dry and clean environment.

10. How do you stay up-to-date on the latest threading technologies?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Network with other threading professionals.

- Take training courses and workshops.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Threading Machine Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Threading Machine Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Threading Machine Setters are responsible for setting up and operating threading machines to produce threaded components. They ensure that the machines are properly adjusted and calibrated to meet the desired specifications and tolerances. Additionally, they monitor the machines during operation and make any necessary adjustments to maintain optimal performance.

1. Machine Setup and Operation

Set up and operate threading machines according to established procedures.

- Load and unload workpieces from the machine.

- Adjust machine settings to achieve desired thread specifications.

- Monitor machine operation and make adjustments as needed.

2. Quality Control

Inspect threaded components to ensure they meet quality standards.

- Check thread dimensions and tolerances using measuring instruments.

- Identify and correct any defects in the threading process.

- Keep records of inspection results.

3. Maintenance and Repair

Perform basic maintenance and repairs on threading machines.

- Lubricate and clean machines regularly.

- Replace worn or damaged parts.

- Troubleshoot and resolve machine malfunctions.

4. Safety and Compliance

Follow all safety regulations and procedures.

- Wear appropriate personal protective equipment (PPE).

- Operate machines in a safe manner.

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are a few tips to help you ace your Threading Machine Setter interview:

1. Research the Company and Position

Take the time to learn about the company’s history, culture, and products. Research the specific role you are applying for and identify the key responsibilities and qualifications.

2. Practice Your Answers

Anticipate common interview questions and prepare thoughtful answers that highlight your skills and experience. Practice delivering your answers out loud to gain confidence and polish your presentation.

3. Be Enthusiastic and Professional

Show enthusiasm for the position and demonstrate your passion for the manufacturing industry. Dress professionally, arrive on time, and maintain a positive attitude throughout the interview.

4. Emphasize Relevant Skills and Experience

Highlight your skills in machine setup, operation, and maintenance. Quantify your accomplishments whenever possible to demonstrate the impact of your work. Use specific examples to showcase your attention to detail and problem-solving abilities.

5. Ask Thoughtful Questions

Asking intelligent questions at the end of the interview shows that you are engaged and interested in the position. Prepare questions related to the company’s growth plans, industry trends, or opportunities for professional development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Threading Machine Setter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.