Are you gearing up for an interview for a Timber Deadener position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Timber Deadener and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

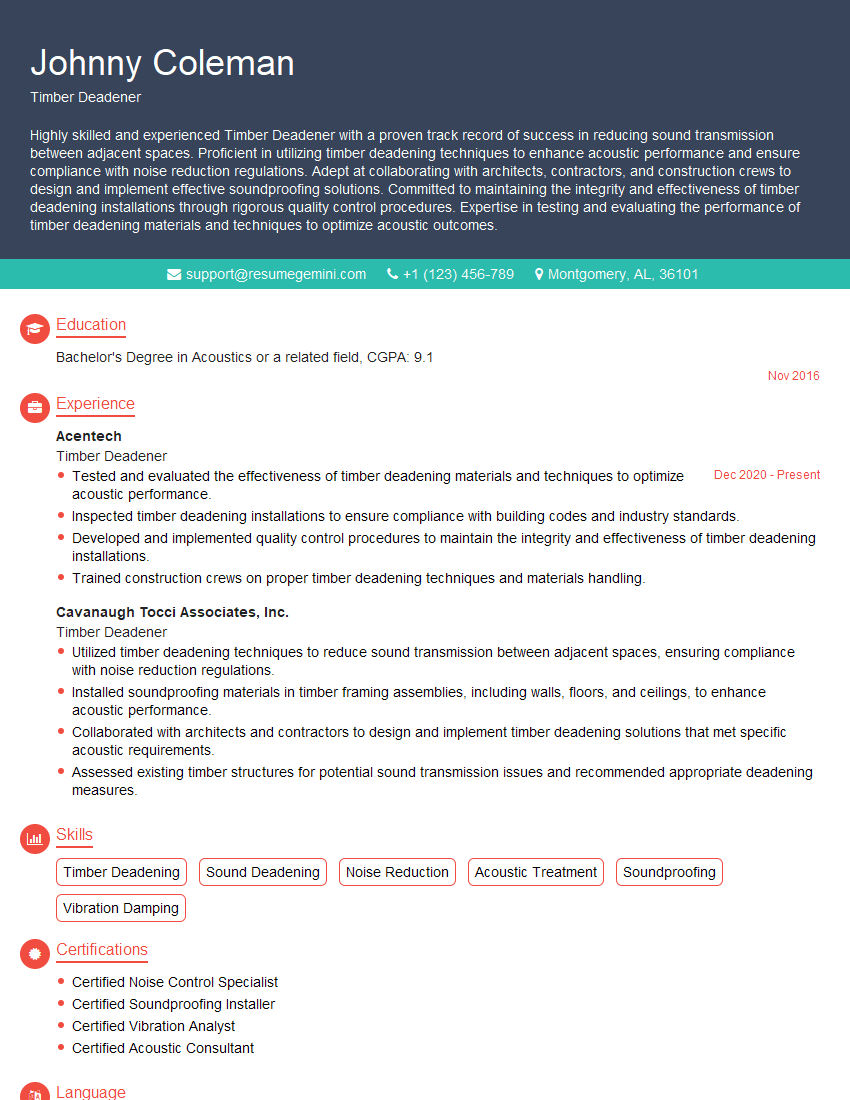

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Timber Deadener

1. What are the different types of timber deadeners and their applications?

Timber deadeners are materials used to reduce noise and vibration in wood construction. There are several types of timber deadeners, each with its own specific applications:

- Felt and rubber deadeners: These are typically used in between layers of wood or metal to absorb and dampen sound and vibration.

- Mass-loaded vinyl (MLV): This is a heavy, flexible material that can be applied to walls, floors, and ceilings to block sound transmission.

- Soundproofing compounds: These are liquid or paste-like materials that can be applied to wood surfaces to create a soundproofing layer.

- Acoustic panels: These are panels made of sound-absorbing materials, such as fiberglass or foam, that can be installed on walls or ceilings to reduce noise levels.

2. What factors should be considered when selecting a timber deadener?

Key factors to consider when selecting a timber deadener include:

- The type of noise or vibration to be reduced. Different types of deadeners are more effective at absorbing different frequencies of sound and vibration.

- The location of the noise or vibration source. This will determine the type of deadener that is most appropriate.

- The budget for the project. Timber deadeners can vary in cost, so it is important to consider the budget when making a selection.

- The ease of installation. Some deadeners are easier to install than others, so it is important to consider the time and effort required for installation.

Additional factors to consider:

- The durability of the deadener.

- The environmental impact of the deadener.

- The aesthetics of the deadener.

3. How do you install timber deadeners?

The installation of timber deadeners typically involves the following steps:

- Preparing the surface: The surface to which the deadener will be applied should be clean, dry, and free of any debris.

- Applying the deadener: The deadener can be applied using a variety of methods, depending on the type of deadener. Some deadeners are self-adhesive, while others require the use of adhesive or nails.

- Finishing the installation: Once the deadener has been applied, it may be necessary to finish the installation by covering it with a protective layer, such as a layer of paint or drywall.

4. What are the benefits of using timber deadeners?

Timber deadeners offer a number of benefits, including:

- Reduced noise levels: Timber deadeners can help to reduce noise levels in a variety of settings, including homes, offices, and industrial buildings.

- Reduced vibration levels: Timber deadeners can also help to reduce vibration levels, which can be beneficial in applications such as machine shops and music studios.

- Improved sound quality: Timber deadeners can help to improve the sound quality in a room by reducing unwanted noise and reverberation.

- Increased privacy: Timber deadeners can help to increase privacy by reducing the amount of sound that can be transmitted through walls and floors.

5. What are some common mistakes to avoid when using timber deadeners?

Some common mistakes to avoid when using timber deadeners include:

- Using the wrong type of deadener: It is important to select the right type of deadener for the specific application.

- Applying the deadener incorrectly: It is important to follow the manufacturer’s instructions for applying the deadener.

- Not covering the deadener: In some cases, it is necessary to cover the deadener with a protective layer, such as a layer of paint or drywall.

- Expecting too much from the deadener: Timber deadeners can help to reduce noise and vibration, but they cannot completely eliminate it.

6. What is the difference between soundproofing and sound absorption?

Soundproofing and sound absorption are two different ways to reduce noise. Soundproofing materials block sound waves from entering or leaving a space, while sound absorption materials absorb sound waves and convert them into other forms of energy, such as heat.

7. What are the different types of soundproofing materials?

There are a variety of soundproofing materials available, including:

- Mass-loaded vinyl (MLV): This is a heavy, flexible material that can be applied to walls, floors, and ceilings to block sound transmission.

- Soundproofing compounds: These are liquid or paste-like materials that can be applied to wood surfaces to create a soundproofing layer.

- Acoustic panels: These are panels made of sound-absorbing materials, such as fiberglass or foam, that can be installed on walls or ceilings to reduce noise levels.

8. What are the different types of sound absorption materials?

There are a variety of sound absorption materials available, including:

- Fiberglass: This is a lightweight, porous material that is commonly used in acoustic panels.

- Foam: This is a lightweight, flexible material that is available in a variety of densities and thicknesses.

- Carpeting: This is a soft, fibrous material that can help to absorb sound waves.

9. What are the benefits of using soundproofing materials?

Soundproofing materials offer a number of benefits, including:

- Reduced noise levels: Soundproofing materials can help to reduce noise levels in a variety of settings, including homes, offices, and industrial buildings.

- Improved privacy: Soundproofing materials can help to increase privacy by reducing the amount of sound that can be transmitted through walls and floors.

- Improved sound quality: Soundproofing materials can help to improve the sound quality in a room by reducing unwanted noise and reverberation.

10. What are the benefits of using sound absorption materials?

Sound absorption materials offer a number of benefits, including:

- Reduced noise levels: Sound absorption materials can help to reduce noise levels in a variety of settings, including homes, offices, and industrial buildings.

- Improved sound quality: Sound absorption materials can help to improve the sound quality in a room by reducing unwanted noise and reverberation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Timber Deadener.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Timber Deadener‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Timber Deadeners are responsible for treating and preserving timber to prevent rot and decay. They apply chemicals to the wood to make it resistant to moisture, insects, and fungi.

1. Timber Treatment

They apply chemical treatments to timber to protect it from decay, rot, and insects.

- Use a variety of methods to apply chemicals, such as spraying, dipping, and brushing.

- Monitor the treatment process to ensure that the timber is properly treated.

2. Timber Inspection

They inspect timber for signs of damage or decay.

- Identify and assess the extent of damage or decay.

- Recommend appropriate treatment options to prevent further damage.

3. Timber Preservation

They preserve timber by applying sealants and coatings.

- Apply sealants and coatings to protect the timber from moisture, UV radiation, and other environmental factors.

- Monitor the condition of the timber and reapply sealants and coatings as needed.

4. Safety and Compliance

They follow safety protocols and regulations.

- Wear appropriate personal protective equipment (PPE) when handling chemicals.

- Follow all safety protocols and regulations related to the use of chemicals and equipment.

Interview Tips

To ace the interview for a Timber Deadener position, it is important to be well-prepared and knowledgeable about the role and the industry.

1. Research the Company and Industry

Research the company and the industry to gain an understanding of their business, values, and market position.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on industry trends.

2. Practice Common Interview Questions

Practice answering common interview questions related to your skills, experience, and qualifications.

- Prepare for questions about your knowledge of timber treatment methods and processes.

- Be ready to discuss your experience in inspecting and preserving timber.

3. Highlight Your Skills and Experience

Highlight your skills and experience that are relevant to the job requirements.

- Emphasize your knowledge of timber treatment chemicals and application methods.

- Showcase your ability to identify and assess timber damage and decay.

4. Be Enthusiastic and Professional

Be enthusiastic and professional throughout the interview.

- Dress appropriately and arrive on time for the interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Timber Deadener interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!