Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Timber Girdler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Timber Girdler so you can tailor your answers to impress potential employers.

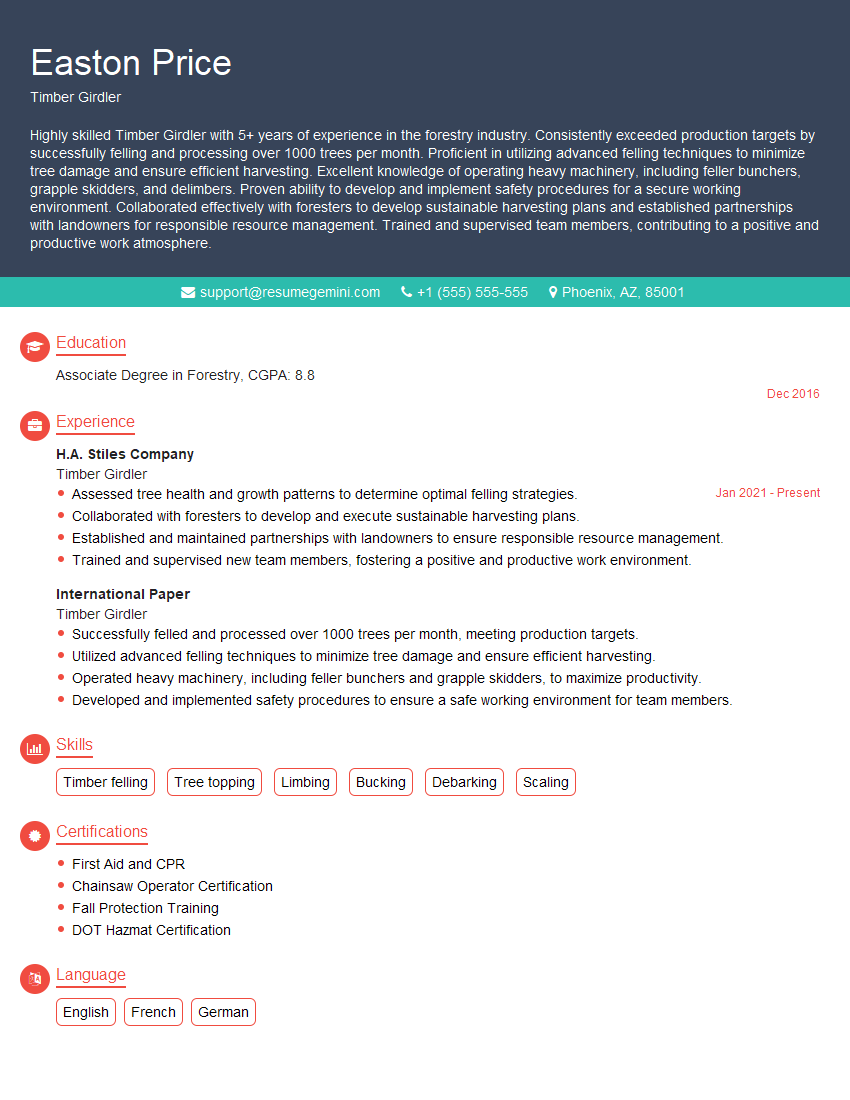

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Timber Girdler

1. What methods and technologies do you use to identify and eliminate timber defects during the production process?

Sample Answer: – Visual inspection: Inspecting the timber for knots, cracks, and other defects. – Machine grading: Using mechanical scanners to detect defects based on density and moisture content.

- X-ray scanning: Using X-rays to detect internal defects.

- Acoustic scanning: Using sound waves to detect internal defects.

- Moisture testing: Measuring moisture content to identify potential defects caused by decay or rot.

2. How do you assess the structural integrity of timber?

Factors to consider

- Timber species: Different species have different strength and durability properties.

- Grain orientation: The direction of the grain can affect the timber’s strength.

- Moisture content: High moisture content can weaken the timber.

- Knots and defects: Knots and other defects can reduce the timber’s strength.

Methods of assessment

- Visual inspection: Inspecting the timber for cracks, knots, and other defects.

- Mechanical testing: Conducting tests to determine the timber’s strength and stiffness.

- Non-destructive testing: Using methods like ultrasonic testing to detect internal defects without damaging the timber.

3. What types of wood treatment methods are used for timber preservation and how do they differ in terms of effectiveness and environmental impact?

Types of Wood Treatment Methods: – Pressure Treatment: – Involves immersing timber in a preservative solution under pressure. – Highly effective in protecting against decay and insects. – Can use water-based or oil-based preservatives. – Non-Pressure Treatment: – Applying preservatives to the surface of the timber. – Less effective than pressure treatment. – Typically used for above-ground applications. – Thermal Treatment: – Heating timber to high temperatures to modify its chemical structure. – Improves durability and resistance to pests. – Can have environmental impacts due to energy consumption. – Chemical Modification: – Treating timber with chemicals to enhance its properties. – Can improve fire resistance, durability, and dimensional stability. – May involve the use of potentially hazardous chemicals. Effectiveness and Environmental Impact: – Pressure treatment is generally the most effective method, but it can have environmental concerns due to chemical leaching. – Non-pressure treatment is less effective but has a lower environmental impact. – Thermal treatment is effective and environmentally friendly, but it can be more expensive. – Chemical modification can be effective but requires careful evaluation of environmental risks.

4. What are the key factors that influence the durability of timber in outdoor applications?

Key Factors Influencing Durability: – Wood Species: Different species have varying natural durability and resistance to decay and pests. – Moisture Content: High moisture content promotes decay and rot. – Exposure to Water: Prolonged exposure to water can lead to swelling, warping, and deterioration. – Ultraviolet (UV) Radiation: UV rays from the sun can degrade the surface of timber and make it more susceptible to damage. – Temperature Fluctuations: Extreme temperature changes can cause timber to expand and contract, leading to cracking and splitting. – Presence of Insects and Fungi: Insects and fungi can feed on timber, causing damage and decay.

5. How do you handle and store timber to minimize damage and maintain its quality?

Handling and Storage Practices: – Proper Piling: Store timber on dry, level ground to prevent warping and bending. – Protection from Moisture: Avoid storing timber in areas with high humidity or direct rain exposure. – Air Circulation: Ensure adequate air circulation around stored timber to prevent moisture build-up. – Protection from Insects and Fungi: Use insecticides and fungicides to protect timber from pests. – Proper Ventilation: Provide ventilation to allow air to circulate and prevent moisture accumulation.

6. Describe the different methods used to join timber and the advantages and disadvantages of each method.

Timber Joining Methods: – Mechanical Joints: – Nails: Simple and cost-effective, but can weaken timber over time. – Screws: Stronger than nails, but more time-consuming to install. – Adhesive Joints: – Wood Glue: Creates strong bonds, but requires proper surface preparation. – Epoxy Adhesive: High-strength adhesive, but can be expensive and requires special handling. – Interlocking Joints: – Dovetail: Strong and aesthetically pleasing, but requires skilled craftsmanship. – Mortise and Tenon: Provides secure and durable joints, but time-consuming to create.

7. What are the principles of structural design for timber structures?

Principles of Structural Design: – Load Analysis: Determining the forces and loads that will act on the structure. – Material Properties: Understanding the strength and behavior of timber. – Structural Elements: Designing individual components (beams, columns, joints) to resist specific loads. – Connection Design: Ensuring that connections between structural elements are strong and reliable. – Stability Analysis: Evaluating the structure’s ability to resist overturning, buckling, and other instability issues.

8. Describe the process of timber seasoning and its importance in enhancing the quality and durability of timber.

Timber Seasoning Process: – Natural Seasoning: Air-drying timber over a long period to reduce moisture content. – Kiln Seasoning: Using controlled heat and humidity to accelerate the seasoning process. – Solar Drying: Utilizing the sun’s heat to evaporate moisture from timber. Importance of Timber Seasoning: – Improved Durability: Seasoning reduces moisture content, making timber less susceptible to decay and rot. – Reduced Warping and Cracking: Seasoning stabilizes the timber’s dimensions, minimizing shrinkage and warping. – Enhanced Strength: Seasoned timber is stronger and more resistant to deformation. – Better Workability: Seasoned timber is easier to saw, nail, and glue.

9. What are the different types of timber grading systems and how do they help in assessing the quality of timber?

Timber Grading Systems: – Visual Grading: Assessing timber quality based on visible characteristics (knots, grain patterns, defects). – Machine Grading: Using machines to determine timber properties (strength, stiffness, density) non-destructively. – Stress Grading: Rating timber based on its ability to withstand specific loads and stresses. – Clear Grading: Classifying timber with minimal defects and high strength for aesthetic or structural applications. Importance of Grading Systems: – Quality Assurance: Grading systems provide a standardized way to evaluate timber quality. – Structural Integrity: Grading helps ensure that timber meets the required strength and performance standards. – Cost Optimization: Grading allows for appropriate selection of timber for different applications, optimizing cost-effectiveness. – Safety and Reliability: Graded timber ensures the safety and reliability of timber structures.

10. How do you stay up-to-date with the latest advancements and trends in timber technology and industry best practices?

Methods to Stay Up-to-Date: – Continuing Education: Attending workshops, seminars, and training programs. – Industry Publications and Webinars: Reading trade magazines, newsletters, and participating in online webinars. – Research and Development: Monitoring industry research and attending conferences to learn about new technologies and innovations. – Professional Organizations: Joining organizations like the National Timber Association (NTA) for access to resources and networking. – Networking and Collaboration: Exchanging knowledge and experiences with colleagues, suppliers, and other industry professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Timber Girdler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Timber Girdler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Timber girdlers play a crucial role in the forestry industry. They are responsible for felling trees and cutting them into logs, ensuring a steady supply of raw materials for production.

1. Felling Trees

Timber girdlers are skilled in using various techniques to fell trees safely and efficiently. They assess the tree’s condition, determine the optimal direction of fall, and use appropriate tools such as axes, chainsaws, and winches to bring the tree down.

- Assess tree condition and determine felling direction

- Use proper felling techniques and equipment

- Maintain a safe work environment

2. Bucking Logs

After felling, timber girdlers cut the tree trunk into logs of specified lengths and diameters. This involves measuring, marking, and using chainsaws or other cutting tools to divide the trunk into manageable segments.

- Measure and mark logs

- Use chainsaws or other cutting tools

- Ensure logs meet specifications

3. Preparing Logs for Transportation

Timber girdlers remove branches, trim logs, and prepare them for transportation. They may use debarkers to remove the outer bark, and use chains, cables, or other equipment to secure logs for loading and transport.

- Remove branches and trim logs

- Debark logs

- Secure logs for transportation

4. Maintaining Equipment

Timber girdlers are responsible for maintaining their own equipment, including chainsaws, axes, and winches. They conduct regular checks, perform minor repairs, and keep their equipment in good working order to ensure safety and efficiency.

- Conduct regular equipment checks

- Perform minor repairs

- Keep equipment in good working order

Interview Tips

Preparing effectively for the Timber Girdler interview can greatly increase your chances of success. Consider the following tips:

1. Research the Company and Position

Take the time to research the company you’re applying to, their values, and their specific needs. Understanding the company’s culture and the role you’re applying for will help you tailor your answers and demonstrate your fit.

- Visit the company website and social media pages

- Read industry news and articles

- Identify specific projects or contributions that align with your skills

2. Practice Your Answers

Anticipate common interview questions and prepare your responses beforehand. Practice answering questions out loud to develop clarity and confidence. Focus on highlighting your relevant skills, experience, and how you can contribute to the company.

- Prepare for questions about your felling techniques, equipment knowledge, and safety protocols

- Explain how your experience aligns with the job requirements

- Rehearse your answers with a friend or family member

3. Know Your Equipment

As a Timber Girdler, you’ll be working with various equipment. Familiarize yourself with the types of chainsaws, axes, winches, and other tools used in timber girdling. Be prepared to discuss your proficiency with this equipment and any safety certifications you hold.

- Describe the different types of chainsaws and their uses

- Explain the safety features and maintenance procedures for equipment

- Discuss your experience with using winches and other log handling equipment

4. Emphasize Safety

Safety is paramount in timber girdling. Highlight your commitment to following safety protocols and maintaining a safe work environment. Discuss your understanding of risk assessment, hazard identification, and emergency procedures.

- Describe your experience with safety training and certifications

- Explain how you prioritize safety in your work

- Share examples of how you have implemented safety measures on the job

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Timber Girdler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Timber Girdler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.