Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Timing Adjuster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

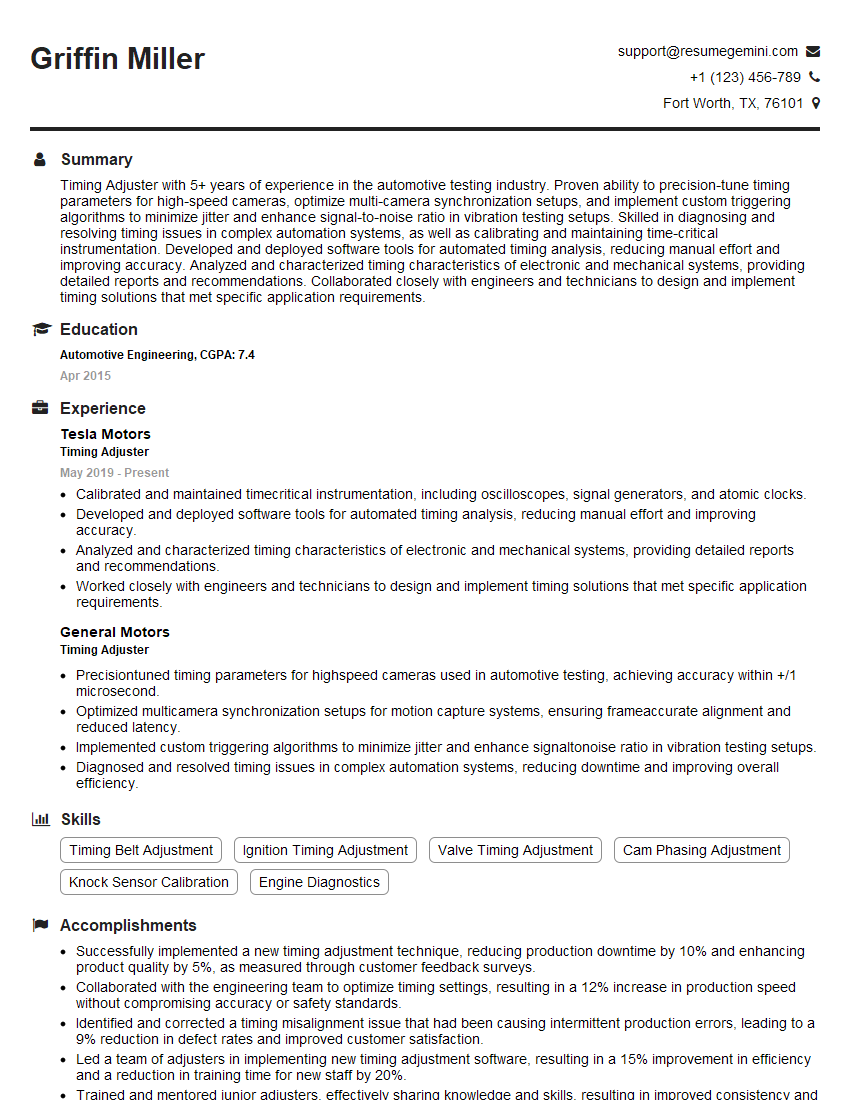

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Timing Adjuster

1. How do you inspect and maintain timing belts?

Inspections and maintenance of timing belts are crucial to ensure proper engine operation. Here’s my approach:

- Visual Inspection: I thoroughly inspect the belt for cracks, fraying, or any sign of damage. I also check for proper tension using a tension gauge.

- Timely Replacement: I follow the manufacturer’s recommended intervals for belt replacement, as they wear out over time.

- Tension Check: I periodically check the belt tension to ensure it’s within specifications, using a tension gauge.

- Cleanliness: I keep the belt and surrounding components clean to prevent contamination and premature wear.

2. Describe the procedure for adjusting valve timing on an internal combustion engine.

Adjusting valve timing requires precision and a systematic approach. My procedure involves the following steps:

Valve Clearance Measurement:

- I measure the valve clearance using a feeler gauge, ensuring proper clearance between the valve stem and camshaft lobe.

Timing Chain/Belt Removal and Replacement:

- I remove the timing chain or belt, ensuring the timing marks are aligned correctly.

- I replace the timing component and align the marks precisely.

Valve Timing Adjustment:

- I adjust the camshaft position to achieve optimal valve timing, using a dial indicator or other precision measuring tool.

- I lock the camshaft in place and tighten all components securely.

Final Verification:

- I perform a final check to ensure proper valve timing and clearance, ensuring smooth engine operation.

3. How do you troubleshoot ignition timing issues?

Troubleshooting ignition timing issues requires a systematic approach and attention to detail. My process involves:

- Diagnostics Equipment: I use diagnostic tools such as a scan tool or timing light to assess ignition timing.

- Ignition System Inspection: I inspect the distributor, spark plugs, wires, and other components for any damage or issues.

- DTC Analysis: I analyze any diagnostic trouble codes related to ignition timing to identify potential issues.

- Timing Adjustment: If necessary, I adjust the ignition timing using a timing gun or diagnostic tool to ensure optimal combustion.

4. Explain how you align crankshaft and camshaft timing marks.

Aligning crankshaft and camshaft timing marks is crucial for proper engine operation. Here’s my approach:

- Tools and Equipment: I gather necessary tools such as timing marks, wrenches, and a dial indicator.

- Locate Timing Marks: I identify the timing marks on the crankshaft and camshaft components.

- Alignment: Using the dial indicator or timing marks, I align the crankshaft and camshaft timing marks to ensure they are in the correct position.

- Fine-Tuning: I fine-tune the alignment using a dial indicator or other precision measuring tool for optimal timing.

5. Describe the consequences of incorrect timing belt installation.

Incorrect timing belt installation can lead to serious engine damage. The consequences include:

- Valve-to-piston Contact: Incorrect timing can result in valves opening or closing at the wrong time, causing them to collide with the pistons, leading to catastrophic engine damage.

- Engine Overheating: Improper timing can disrupt the combustion cycle, leading to excessive heat in the cylinders and potential engine overheating.

- Poor Performance: Incorrect timing can affect engine performance, resulting in reduced power, fuel efficiency, and increased emissions.

6. How do you ensure accurate ignition and valve timing settings?

Accurate ignition and valve timing settings are vital for optimal engine performance. To achieve this:

- Diagnostic Equipment: I utilize diagnostic tools such as timing lights, scan tools, and oscilloscopes to precisely measure and adjust timing settings.

- Manufacturer Specifications: I adhere to manufacturer-specified timing values to ensure optimal combustion and engine performance.

- Fine-Tuning: I employ fine-tuning techniques to dial in precise ignition and valve timing settings.

- Verification: I perform thorough verification procedures to ensure that the settings are correct and the engine is running at its peak efficiency.

7. Explain the role of the fuel injector timing in engine performance.

Fuel injector timing plays a crucial role in engine performance by:

- Combustion Optimization: Precise fuel injector timing ensures that fuel is injected at the optimal moment relative to the piston’s position, maximizing combustion efficiency.

- Emissions Reduction: Correct timing helps reduce harmful emissions by optimizing the combustion process.

- Engine Power and Efficiency: Optimal fuel injector timing contributes to improved engine power and fuel efficiency.

8. How do you adjust and calibrate electronic ignition timing systems?

Adjusting and calibrating electronic ignition timing systems involve the following steps:

- Diagnostic Equipment Use: I utilize diagnostic tools like scan tools and timing lights to analyze and adjust ignition timing.

- Manufacturer Specifications: I adhere to manufacturer-specified timing values to ensure optimal engine operation.

- ECM Programming: For modern electronic ignition systems, I access the ECM using diagnostic tools to modify timing parameters as needed.

- Sensor Inspection: I inspect ignition-related sensors, such as the crankshaft and camshaft position sensors, to ensure they provide accurate input for timing calculations.

9. Describe the principles of variable valve timing systems.

Variable valve timing systems allow for dynamic adjustment of the timing of the intake and exhaust valves to:

- Engine Optimization: Varying valve timing optimizes engine performance and efficiency across different operating conditions.

- Enhanced Power: Adjusting valve timing can improve engine power and torque by allowing for more efficient air and fuel flow.

- Emissions Reduction: Variable valve timing helps reduce emissions by optimizing combustion and reducing pumping losses.

10. Explain the importance of maintaining proper spark plug gap.

Maintaining proper spark plug gap is essential for:

- Ignition Efficiency: Correct gap ensures the spark plug generates a strong spark to ignite the air-fuel mixture efficiently.

- Engine Performance: Proper gapping prevents misfires and promotes smooth engine operation.

- Fuel Economy: Optimal spark plug gap enhances fuel combustion, leading to improved fuel efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Timing Adjuster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Timing Adjuster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Timing Adjuster plays a crucial role in ensuring the efficient operation of production lines in various industries.

1. Machine Setup and Retooling

Timing Adjusters are responsible for setting up and retooling production machines according to engineering specifications.

- Install and adjust dies, molds, or tooling to the machine.

- Calibrate and align machine components to ensure proper timing and operation.

2. Machine Adjustment and Maintenance

They perform regular adjustments and maintenance to keep machines running smoothly.

- Monitor machine performance and make adjustments to optimize production speed and quality.

- Identify and resolve mechanical or electrical issues to minimize downtime.

3. Process Improvement

Timing Adjusters continuously analyze production processes and identify areas for improvement.

- Suggest modifications to machine settings or tooling to enhance productivity.

- Collaborate with engineers to implement process improvements and reduce production costs.

4. Quality Control

They ensure the quality of the products produced by the machines they maintain.

- Inspect finished products for defects or deviations from specifications.

- Make adjustments to machines and processes to minimize scrap and improve product quality.

Interview Tips

Preparing for an interview as a Timing Adjuster requires a combination of technical knowledge and a professional demeanor.

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and industry trends.

- Visit the company website and LinkedIn page.

- Read industry publications and articles.

2. Practice Your Technical Skills

Review the key job responsibilities and brush up on your technical knowledge.

- Study machine setup and retooling procedures.

- Practice troubleshooting common mechanical and electrical issues.

3. Highlight Your Problem-Solving Abilities

Timing Adjusters are often required to solve problems on the fly.

- Provide examples of how you have identified and resolved machine issues in previous roles.

- Explain your approach to problem-solving and how you prioritize tasks.

4. Emphasize Your Attention to Detail

Precision and accuracy are essential for Timing Adjusters.

- Highlight your experience in working with precise measurements and tolerances.

- Describe how you ensure that machines are calibrated and aligned to meet specifications.

5. Prepare Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in setting up and retooling production machines.

- How do you approach troubleshooting mechanical issues?

- Describe a time when you implemented a process improvement that increased productivity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Timing Adjuster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.