Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tin Pourer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

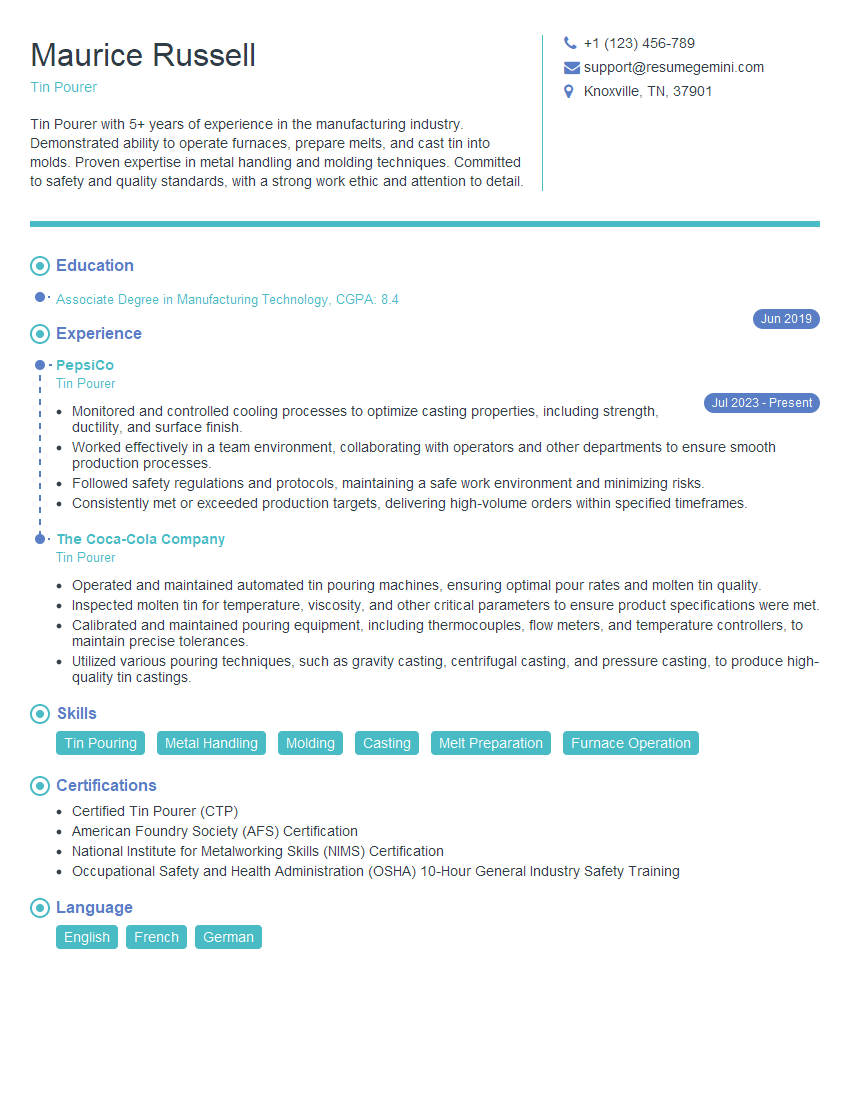

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tin Pourer

1. How would you determine the correct pouring temperature for a specific alloy?

I would refer to the manufacturer’s specifications for the alloy in question. Different alloys have different pouring temperatures that optimize their properties and avoid defects.

2. What are the key factors to consider when selecting a pouring flux?

Composition

- Fluxes should match the alloy being poured to ensure proper cleaning and degassing.

Activity level

- The activity level of the flux should be appropriate for the specific alloy and pouring conditions.

3. Describe the steps involved in preparing a mold for pouring.

- Clean the mold thoroughly to remove any dirt or debris.

- Apply a mold release agent to prevent sticking.

- Preheat the mold to the appropriate temperature for the alloy being poured.

4. How do you control the flow of molten metal during pouring?

- Use a pouring spout or crucible designed for controlled pouring.

- Maintain a steady and even pouring rate.

- Tilt the mold or casting appropriately to ensure proper filling.

5. What are the potential hazards associated with tin pouring and how can they be mitigated?

- Burns: Wear protective clothing, gloves, and eye protection.

- Fumes: Use proper ventilation and respiratory protection.

- Explosions: Avoid pouring molten metal into wet or contaminated molds.

6. How do you troubleshoot common defects in castings, such as porosity or shrinkage?

- Porosity: Check pouring temperature, mold preparation, and flux effectiveness.

- Shrinkage: Adjust pouring temperature, mold design, or alloy composition.

7. Describe the different types of casting processes used for tin and their respective advantages and disadvantages.

Sand casting

- Advantages: Low cost, versatile.

- Disadvantages: Rough surface finish, dimensional limitations.

Investment casting

- Advantages: High precision, smooth surface finish.

- Disadvantages: Expensive, complex process.

8. How do you ensure the quality of tin castings?

- Follow proper pouring and casting techniques.

- Inspect castings for defects using visual inspection or non-destructive testing.

- Maintain equipment and tools regularly.

9. What are the key properties of tin that make it suitable for casting?

- Low melting point.

- Excellent fluidity.

- Resistance to corrosion.

10. Describe your experience with different tin alloys and their applications.

I have experience working with a range of tin alloys, including pewter, solder, and babbitt. Each alloy has its own unique properties and applications. For example, pewter is used for decorative items, solder for electrical connections, and babbitt for bearings.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tin Pourer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tin Pourer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tin Pourers are responsible for operating machines that pour molten tin onto metal sheets to coat them. They play a vital role in ensuring the quality and durability of tin-coated products.

1. Operating Tin Pouring Machines

Tin Pourers are skilled in operating tin pouring machines. They set up the machine, adjust controls, and pour molten tin onto metal sheets accurately.

2. Maintaining Tin Quality

Tin Pourers are responsible for maintaining the quality of the molten tin. They monitor the temperature and composition of the tin, and make adjustments as necessary.

3. Ensuring Product Quality

Tin Pourers are responsible for ensuring the quality of the tin-coated products. They inspect the sheets for defects, and make adjustments to the machine or process as needed.

4. Maintaining a Clean and Safe Work Environment

Tin Pourers are responsible for maintaining a clean and safe work environment. They follow safety protocols, and keep the work area free of hazards.

Interview Tips

Interviewing for a Tin Pourer position can be competitive. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take some time to research the company and the Tin Pourer position. This will help you understand the company’s culture, products, and goals. It will also help you tailor your answers to the specific requirements of the job.

2. Practice Your Answers

Take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

3. Be Professional and Enthusiastic

Dress professionally and arrive on time for your interview. Be polite and respectful to the interviewer, and show enthusiasm for the position.

4. Highlight Your Skills and Experience

During the interview, be sure to highlight your skills and experience that are relevant to the Tin Pourer position. Quantify your accomplishments whenever possible, and use specific examples to illustrate your abilities.

5. Ask Questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are engaged and interested in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tin Pourer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!