Are you gearing up for an interview for a Tin Whiz Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tin Whiz Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

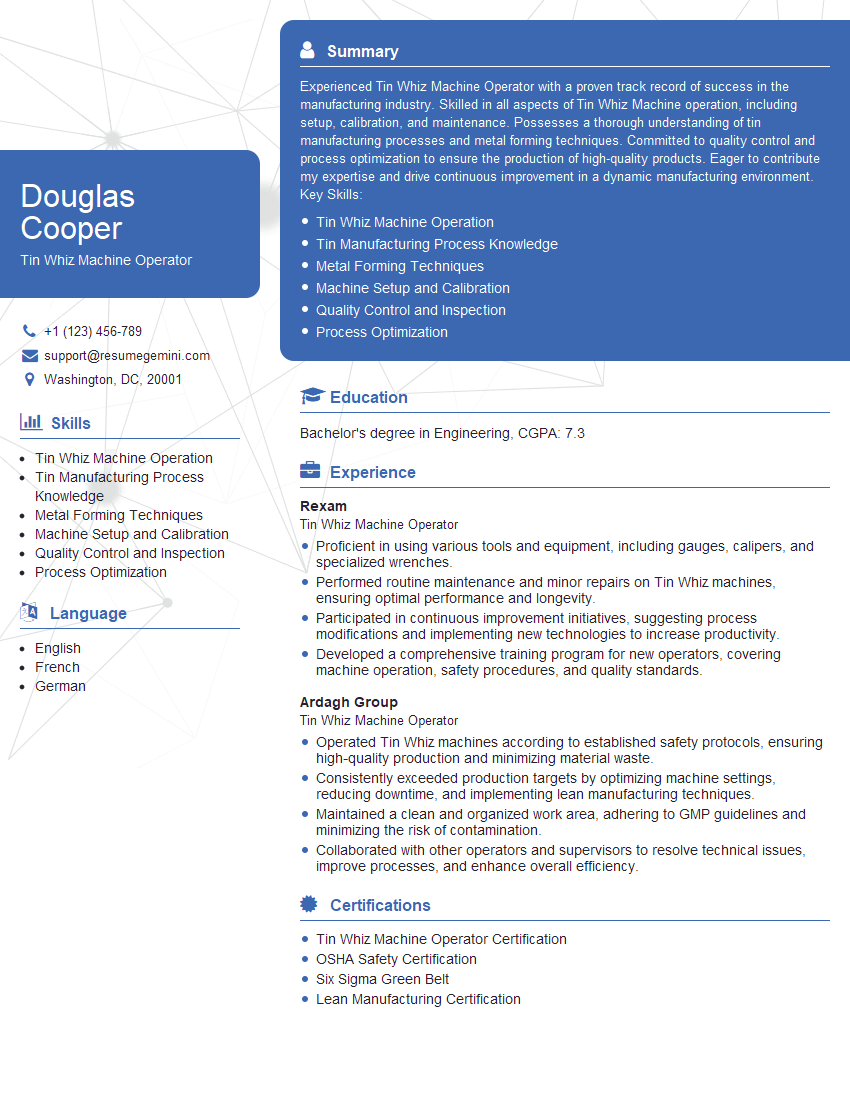

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tin Whiz Machine Operator

1. What are the key operational principles of a Tin Whiz Machine?

The Tin Whiz Machine is a metalworking machine used for cutting and forming sheet metal. It operates on the principles of hydraulics and pneumatics.

- The machine is powered by a hydraulic system that provides the force necessary to cut and form the metal. The hydraulic system consists of a hydraulic pump, a reservoir, and a series of valves and cylinders.

- The machine is also equipped with a pneumatic system that provides the air pressure necessary to operate the machine’s tools. The pneumatic system consists of an air compressor, a reservoir, and a series of valves and cylinders.

2. Describe the process of setting up and operating a Tin Whiz Machine.

Pre-Operation Setup

- Inspect the machine for any damage or loose parts.

- Secure the sheet metal to the machine’s table.

- Select the appropriate cutting or forming tool and install it in the machine.

- Set the machine’s cutting or forming parameters.

Operation

- Start the machine and allow it to reach operating speed.

- Guide the sheet metal through the machine’s cutting or forming tools.

- Monitor the machine’s operation and make adjustments as necessary.

3. What are the common maintenance tasks required for a Tin Whiz Machine?

The common maintenance tasks required for a Tin Whiz Machine include:

- Cleaning and lubricating the machine’s moving parts.

- Inspecting the machine’s hydraulic and pneumatic systems for leaks or damage.

- Replacing worn or damaged parts.

- Calibrating the machine’s cutting or forming parameters.

4. What are the safety precautions that must be taken when operating a Tin Whiz Machine?

The safety precautions that must be taken when operating a Tin Whiz Machine include:

- Wearing appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keeping the machine’s work area clean and free of debris.

- Never reaching into the machine’s cutting or forming area while it is operating.

- Shutting off the machine and disconnecting the power supply before performing any maintenance or repairs.

5. What are the different types of sheet metal that can be processed using a Tin Whiz Machine?

The different types of sheet metal that can be processed using a Tin Whiz Machine include:

- Mild steel

- Stainless steel

- Aluminum

- Copper

- Brass

6. What are the different cutting and forming operations that can be performed using a Tin Whiz Machine?

The different cutting and forming operations that can be performed using a Tin Whiz Machine include:

- Cutting

- Bending

- Forming

- Punching

- Notching

7. What are the advantages of using a Tin Whiz Machine over other metalworking machines?

The advantages of using a Tin Whiz Machine over other metalworking machines include:

- Accuracy

- Speed

- Versatility

- Durability

- Ease of use

8. What are the challenges of operating a Tin Whiz Machine?

The challenges of operating a Tin Whiz Machine include:

- The machine’s complex controls.

- The need for specialized training to operate the machine safely and efficiently.

- The potential for accidents if the machine is not operated properly.

9. What is your experience with operating a Tin Whiz Machine?

I have been operating a Tin Whiz Machine for the past 5 years. During that time, I have used the machine to produce a wide variety of metal products, including ductwork, electrical enclosures, and automotive parts. I am proficient in all aspects of the machine’s operation, including setup, operation, and maintenance.

10. Why do you think you are the right person for this job?

I am confident that I am the right person for this job because I have the skills and experience necessary to operate a Tin Whiz Machine safely and efficiently. I am also a hard worker and I am always willing to learn new things. I am confident that I can be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tin Whiz Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tin Whiz Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tin Whiz Machine Operators play a crucial role in manufacturing operations, utilizing specialized machinery to complete various tasks. Their responsibilities encompass several key areas:

1. Machine Operation and Maintenance

Operate and monitor Tin Whiz machines, ensuring efficient production of metal cans and other containers.

- Maintain and troubleshoot machines, performing routine inspections and repairs as necessary.

- Calibrate and adjust machines to ensure optimal performance and meet quality standards.

2. Quality Control and Inspection

Inspect finished products to verify their compliance with specifications and quality standards.

- Identify and rectify defects or inconsistencies in product quality.

- Document inspection results and maintain quality records for traceability and compliance.

3. Production Optimization

Monitor production processes and identify areas for improvement, enhancing efficiency and reducing waste.

- Suggest and implement operational improvements to increase productivity and minimize downtime.

- Collaborate with team members to optimize workflow and establish best practices.

4. Safety and Compliance

Adhere to all safety regulations and procedures, ensuring a safe and compliant work environment.

- Identify and mitigate potential hazards, implementing preventive measures to minimize risks.

- Wear appropriate personal protective equipment (PPE) and follow established safety protocols.

Interview Tips

To ace an interview for a Tin Whiz Machine Operator position, it’s essential to prepare thoroughly. Here are some tips and strategies to help you succeed:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and products to demonstrate your interest and knowledge. Research the job description to understand the specific requirements and expectations of the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles related to the field.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Provide specific examples of your machine operation and maintenance experience.

- Showcase your quality control and inspection abilities, highlighting your attention to detail and commitment to meeting standards.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your skills, experience, and motivation. Practice delivering concise and well-structured answers that highlight your strengths and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to provide clear and compelling examples.

- Consider questions about safety procedures, quality control measures, and production optimization techniques.

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and the industry. Maintain a professional demeanor throughout the interview, dressing appropriately and arriving on time. Be polite and respectful to everyone you encounter, including the receptionist and other employees.

- Show your interest in the company’s products and mission.

- Be confident in your abilities but avoid being arrogant or overbearing.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tin Whiz Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.