Are you gearing up for a career in Tinner Helper? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tinner Helper and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tinner Helper

1. How would you measure the amount of solder required to fill a joint?

- Emphasize the importance of calculating the joint’s volume.

- Explain that the volume can be determined by multiplying the length, width, and depth of the joint.

- State that the amount of solder required can be calculated by dividing the joint’s volume by the density of solder.

2. What are the common methods used to apply solder to a joint?

Hand Soldering

- Describe the process of using a soldering iron to melt solder onto the joint.

- Mention the different types of soldering irons and their uses.

Wave Soldering

- Explain the technique of passing a PCB through a wave of molten solder.

- Highlight the benefits of wave soldering, such as high speed and low cost.

3. How would you inspect a solder joint to ensure its quality?

- Explain the importance of visual inspection.

- Describe the use of magnifying glasses or microscopes to identify defects.

- Mention the different types of defects that can occur and how to identify them.

- Discuss the use of non-destructive testing methods, such as X-ray or ultrasonic inspection.

4. What are the different types of solder fluxes used in soldering?

- Explain the role of fluxes in removing oxides and promoting solder flow.

- Describe the different types of fluxes, such as water-soluble, rosin-based, and no-clean fluxes.

- Discuss the advantages and disadvantages of each type.

5. How would you ensure electrical continuity after soldering?

- Explain the importance of proper circuit design.

- Describe the use of solderability testing to verify the joint’s electrical properties.

- Mention the use of continuity testers or multimeters to check for proper electrical connectivity.

6. What are the common safety precautions that should be taken while soldering?

- Emphasize the importance of wearing appropriate personal protective equipment (PPE).

- Explain the dangers of soldering fumes and how to minimize exposure.

- Discuss the risks of burns and how to prevent them.

- Mention the importance of proper ventilation and maintaining a clean work area.

7. What are the physical and chemical properties of solder that make it suitable for electrical connections?

Physical Properties

- Explain that solder is a low-melting point alloy.

- Discuss the electrical conductivity and mechanical strength of solder.

Chemical Properties

- Describe the ability of solder to form metallurgical bonds with metals.

- Explain the corrosion resistance of solder.

8. How would you troubleshoot a faulty solder joint?

- Explain the importance of identifying the cause of the fault.

- Describe the use of visual inspection, electrical testing, and other diagnostic methods.

- Discuss the steps involved in repairing the solder joint and restoring electrical continuity.

9. What are the emerging trends and advancements in the field of soldering?

- Explain the increasing use of lead-free solders.

- Discuss the adoption of automated soldering processes.

- Mention the development of new soldering materials and techniques.

10. How do you stay updated with the latest industry standards and best practices in soldering?

- Emphasize the importance of attending industry conferences and workshops.

- Explain the role of professional organizations and certification programs.

- Mention the use of online resources and technical publications.

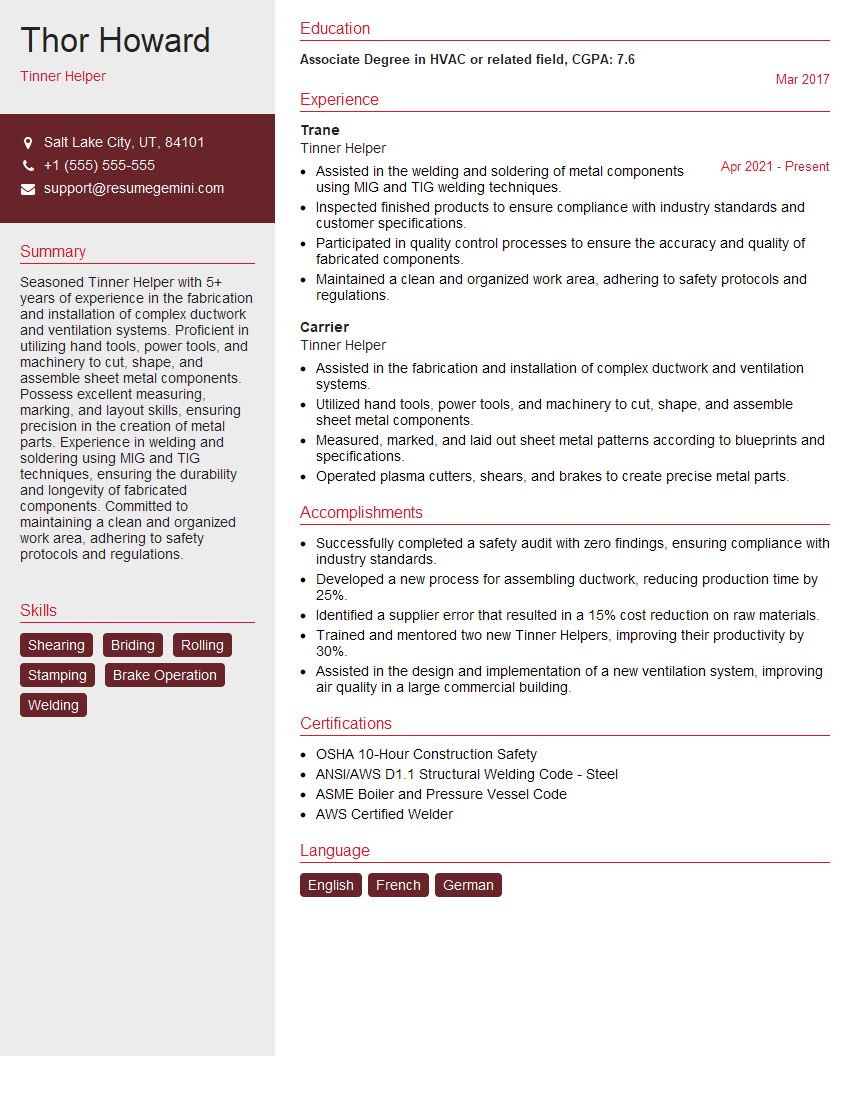

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tinner Helper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tinner Helper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tinner Helper is responsible for assisting experienced tinners in the fabrication and installation of sheet metal, promising customer satisfaction. Their daily tasks may include the following:

1. Preparing materials

The candidate would assist in feeding sheet metal, measuring and marking materials, preparing layout and patterns, and setting up tools and equipment.

2. Installing sheet metal

The candidate would fasten sheet metal to studs and joists, using nails, screws, or other fasteners, assemble and install components, such as ducts, flashing, and gutters, and seal joints and seams to ensure proper sealing.

3. Bending and shaping sheet metal

The candidate would operate hand or power tools to bend and shape sheet metal, following blueprints or instructions, measure and cut sheet metal using hand and power tools, and ensure that the finished product meets specifications.

4. Inspecting and maintaining tools and equipment

The candidate would check tools and equipment for proper operation and make adjustments or repairs as needed, ensure that tools and equipment are clean and organized, and identify any potential hazards and take appropriate action to mitigate risks.

Interview Tips

To ace the interview, here are some valuable preparation tips:

1. Research the company and job

Demonstrate your interest and enthusiasm by learning about the company’s history, mission, and values. Understand the specific responsibilities of the Tinner Helper role and how your skills and experience align with the requirements.

2. Practice common interview questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?” and “What are your strengths and weaknesses?” Tailor your responses to highlight your relevant skills and how you can contribute to the company.

3. Prepare questions for the interviewer

Asking thoughtful questions shows that you are engaged and interested in the position. Prepare questions about the company culture, growth opportunities, and the specific projects you would be working on. This also demonstrates your proactive nature.

4. Dress professionally and arrive on time

First impressions matter. Dress appropriately for the interview and arrive on time to show respect for the interviewer’s schedule. Maintain good posture and make eye contact during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tinner Helper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!