Feeling lost in a sea of interview questions? Landed that dream interview for Tinware Lithograph Press Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tinware Lithograph Press Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

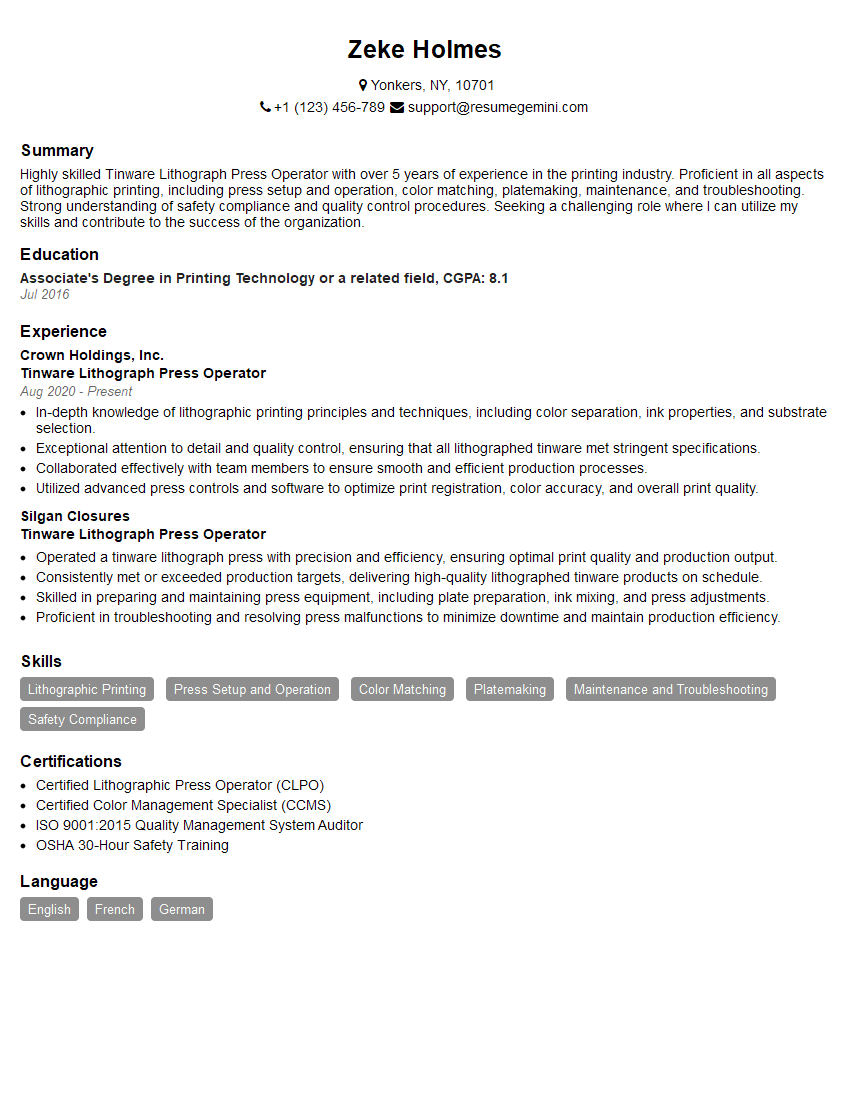

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tinware Lithograph Press Operator

1. Describe the process of preparing a tinware lithograph press.

To prepare a tinware lithograph press, I first need to gather the necessary materials, including the tinware, lithograph plates, ink, and press. I then need to clean the press and the tinware to ensure that there is no dirt or debris that could interfere with the printing process. After that, I need to set up the press by mounting the lithograph plates and adjusting the ink rollers. Finally, I need to test the press to make sure that it is printing correctly before proceeding with the actual printing job.

2. How do you ensure that the lithograph plates are properly aligned on the press?

Alignment Techniques

- I use a precision alignment tool to ensure that the lithograph plates are properly aligned on the press.

- I also use a magnifying glass to check the alignment of the plates and make any necessary adjustments.

Experience

- With my experience in operating tinware lithograph presses, I have developed a keen eye for alignment, which allows me to quickly and accurately align the plates.

3. What are the different types of ink that can be used in tinware lithography?

- Oil-based ink is the most common type of ink used in tinware lithography.

- Water-based ink is also an option, but it is less durable than oil-based ink.

- UV-curable ink is a newer type of ink that is becoming more popular due to its quick drying time and durability.

4. How do you adjust the ink flow on a tinware lithograph press?

- The ink flow on a tinware lithograph press is adjusted by using a series of ink keys.

- Each ink key corresponds to a different color of ink, and by adjusting the key, I can control the amount of ink that is applied to the press.

- I use a densitometer to measure the ink density and make sure that it is within the desired range.

5. What is the difference between a single-color and a multi-color tinware lithograph press?

- A single-color tinware lithograph press can only print one color at a time.

- A multi-color tinware lithograph press can print multiple colors at the same time.

- Multi-color presses are more complex to operate than single-color presses, but they can produce more complex and vibrant prints.

6. What are the most common problems that can occur when operating a tinware lithograph press?

- Misalignment of the lithograph plates

- Incorrect ink flow

- Improper tension on the tinware

- Dirt or debris on the press or the tinware

- Mechanical problems with the press

7. How do you troubleshoot a tinware lithograph press that is not printing correctly?

When troubleshooting a tinware lithograph press that is not printing correctly, I first need to identify the source of the problem. I will check the alignment of the lithograph plates, the ink flow, the tension on the tinware, and the cleanliness of the press and the tinware. If I cannot find any obvious problems, I will then check the mechanical components of the press for any damage or wear. Once I have identified the source of the problem, I will take steps to correct it and get the press printing correctly again.

8. What safety precautions should be taken when operating a tinware lithograph press?

- Always wear appropriate safety gear, including gloves, safety glasses, and a mask.

- Never operate the press with loose clothing or jewelry that could get caught in the machinery.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button and know how to use it.

- Follow all manufacturer’s instructions for safe operation of the press.

9. What is your experience with operating tinware lithograph presses?

- I have been operating tinware lithograph presses for the past 5 years.

- In that time, I have printed a wide variety of products, including food containers, beverage cans, and decorative items.

- I am proficient in all aspects of tinware lithography, including press setup, plate alignment, ink adjustment, and troubleshooting.

10. Why are you interested in working as a Tinware Lithograph Press Operator at our company?

I am interested in working as a Tinware Lithograph Press Operator at your company because I am passionate about the printing process and I am eager to learn more about the tinware lithography industry. I am also confident that my skills and experience would be a valuable asset to your team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tinware Lithograph Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tinware Lithograph Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Tinware Lithograph Press Operator, you will be responsible for operating, maintaining, and setting up high-speed presses that manufacture tinware lithographed products.

1. Press Operation

You will be in charge of the overall operation of the press, including loading and unloading the press, adjusting the press settings, and monitoring the press performance.

- Set up and operate tinware lithograph presses to produce a variety of products.

- Monitor press operation and make adjustments as needed to ensure quality and efficiency.

- Inspect tinware products for quality and ensure they meet specifications.

2. Press Maintenance

You will also be responsible for maintaining the press, including cleaning and lubricating the press, performing minor repairs, and following a regular maintenance schedule.

- Perform preventive maintenance on presses to prevent breakdowns and ensure smooth operation.

- Troubleshoot and repair press malfunctions to minimize downtime and maintain production efficiency.

- Maintain accurate records of press maintenance and repairs for future reference.

3. Material Handling

You will be responsible for handling the materials used in the press operation, including loading and unloading the press, and stacking and storing the finished products.

- Load and unload raw materials and finished products from the press.

- Stack and store finished products in a safe and organized manner to prevent damage.

- Operate forklifts or other material handling equipment to move materials as needed.

4. Quality Control

You will be responsible for ensuring the quality of the products produced by the press, which will involve inspecting the products for defects and making adjustments to the press to minimize defects.

- Conduct quality checks on tinware products to ensure they meet specifications and standards.

- Identify and resolve quality issues by adjusting press settings and implementing corrective actions.

- Maintain quality records and documentation to track and monitor product quality levels.

Interview Tips

Preparing for an interview for a Tinware Lithograph Press Operator position requires a combination of research, practice, and self-reflection.

1. Research the Company and Position

Before you even start preparing your answers, take some time to research the company you’re applying to and the specific position you’re interested in. This will help you understand the company’s culture, values, and the specific skills and experience they’re looking for in a candidate.

- Visit the company’s website and social media pages.

- Read industry news and articles to stay up-to-date on the latest trends.

- Reach out to your network to see if anyone has any insights or connections.

2. Practice Your Answers

Once you have a good understanding of the company and position, it’s time to start practicing your answers to common interview questions. Some of the most common questions you can expect to be asked in an interview for a Tinware Lithograph Press Operator position include:

- “Tell me about your experience operating tinware lithograph presses.”

- “What are your strengths and weaknesses as a press operator?”

- “How do you handle working in a fast-paced environment?”

By practicing your answers ahead of time, you can feel more confident and prepared during the interview.

3. Be Yourself and Be Enthusiastic

It’s important to be yourself and be enthusiastic during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. And if you’re passionate about working as a Tinware Lithograph Press Operator, let your enthusiasm shine through. Your positive attitude will make a great impression on the interviewer.

- Dress professionally and arrive on time for your interview.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be honest and open about your experience and skills.

- Ask questions about the company and position to show your interest.

4. Prepare Questions to Ask

At the end of the interview, the interviewer will likely ask if you have any questions. This is your chance to learn more about the company and position, so prepare a few questions to ask. Some good questions to ask include:

- “What are the biggest challenges facing the company right now?”

- “What are the company’s plans for growth in the future?”

- “What is the company culture like?”

Asking thoughtful questions shows that you’re engaged and interested in the position.

5. Follow Up

After the interview, follow up with the interviewer to thank them for their time and reiterate your interest in the position. This shows that you’re still interested in the job and that you’re willing to go the extra mile.

- Send a thank-you email within 24 hours of the interview.

- Reiterate your interest in the position and highlight your key skills and experience.

- Let the interviewer know that you’re available for a second interview or any additional steps in the hiring process.

By following these tips, you can prepare for and ace your interview for a Tinware Lithograph Press Operator position.

Next Step:

Now that you’re armed with the knowledge of Tinware Lithograph Press Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tinware Lithograph Press Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini