Are you gearing up for a career in Tip Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tip Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

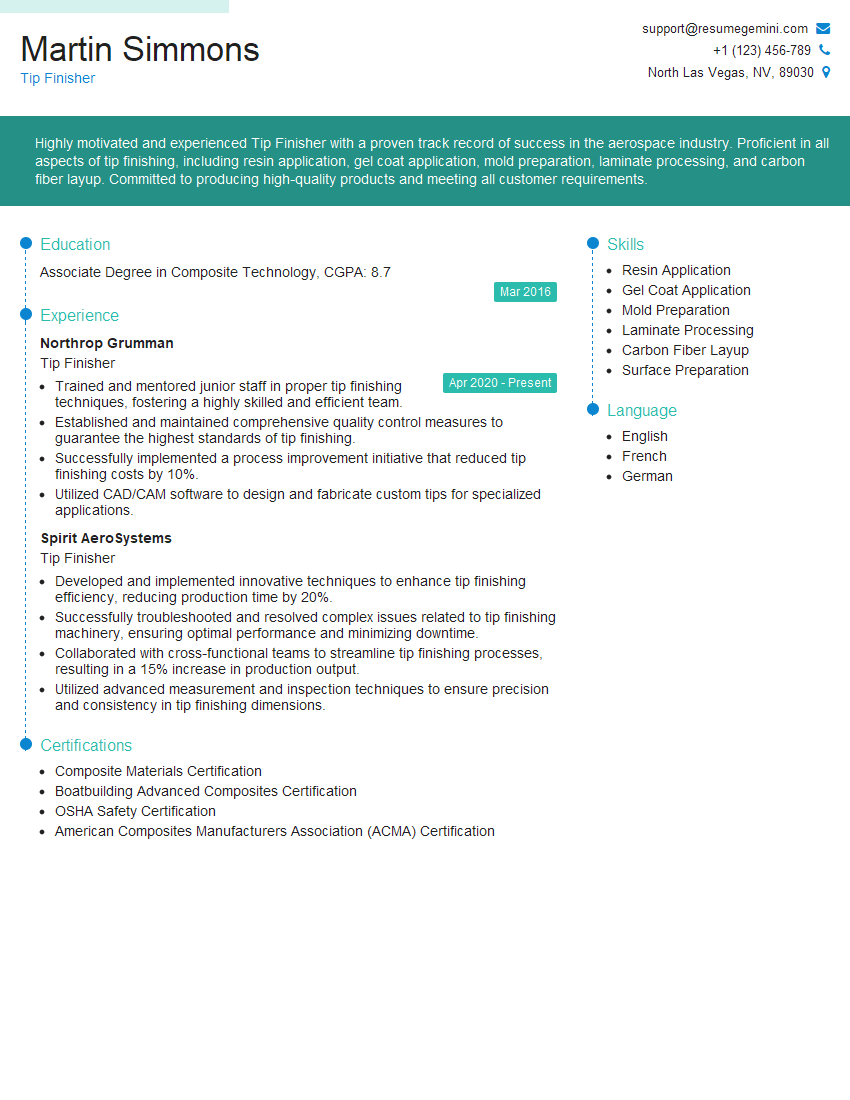

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tip Finisher

1. What are the steps involved in tipping a shoe?

- Prepare the tip by trimming the excess leather in equal amounts from both sides.

- Apply cement along the inside edge of the tip.

- Moisten the tip with water to activate the cement.

- Fold the tip over the toes of the shoe, making sure the edges align.

- Secure the tip with nails or clamps and allow it to dry completely.

2. What are the important factors to consider when selecting the tip material for a shoe?

Durability

- Consider the intended use of the shoe and the amount of wear it will receive.

- Materials like leather and rubber are durable and can withstand heavy use.

Flexibility

- Choose a material that allows for some flexibility to prevent cracking or tearing.

- Materials like synthetic leather and vinyl offer flexibility while maintaining durability.

Style and aesthetics

- The tip material should complement the overall design and style of the shoe.

- Consider the color, texture, and grain of the material.

3. How do you ensure a proper fit of the tip on the shoe?

- Measure the toes of the shoe to determine the appropriate tip size.

- Trim the excess leather from the tip to match the size of the toes.

- Test-fit the tip on the shoe before applying cement to ensure a snug fit.

- Use nails or clamps to secure the tip tightly to the toes.

4. What are the different types of tips available for shoes?

- Cap toe: A rounded or square-shaped tip that covers the toes completely.

- Wingtip: A tip with extended flaps or “wings” on either side.

- Brogue: A perforated or decorative tip with intricate patterns.

- Monk strap: A tip with a strap and buckle closure.

- Loafer: A slip-on shoe with a rounded or square tip.

5. What are the common problems that can occur during the tipping process and how can they be prevented?

Wrinkles or bubbles

- Caused by insufficient moisture or uneven application of cement.

- Use a damp cloth to smooth out wrinkles or bubbles and reapply cement if necessary.

Misalignment

- Caused by incorrect placement of the tip or uneven trimming.

- Reposition the tip as needed and secure with nails or clamps to ensure proper alignment.

Cracking or tearing

- Caused by using a material that is too stiff or brittle.

- Select a tip material that is flexible and can withstand the wear and tear of the shoe.

6. How do you prepare the leather before tipping?

- Clean the surface of the leather to remove any dirt or debris.

- Roughen the leather slightly using sandpaper or a wire brush to create adhesion.

- Apply a thin layer of cement to the prepared area.

7. What is the ideal temperature and humidity for tipping shoes?

- The ideal temperature is between 65-75°F (18-24°C).

- Relative humidity should be around 50-60%.

8. What are the safety precautions that should be taken when using cement for tipping shoes?

- Wear gloves and eye protection to avoid contact with cement.

- Work in a well-ventilated area to prevent inhalation of fumes.

- Keep cement away from heat sources to avoid combustion.

9. How do you troubleshoot problems with the tip finish?

Uneven finish

- Check the sanding or buffing technique to ensure even coverage.

- Use different grades of sandpaper or buffing wheels to achieve the desired finish.

Discoloration

- Check if the dye or paint is applied evenly.

- Use a color corrector or touch-up paint to even out the color.

Scratches or dents

- Use sandpaper or leather repair filler to remove scratches or dents.

- Apply a shoe cream or polish to conceal any imperfections.

10. How do you ensure quality control in the tipping process?

- Use high-quality materials and equipment for durability and precision.

- Conduct regular inspections at various stages of the process to identify any defects.

- Train and monitor staff to ensure proper techniques and safety measures are followed.

- Establish quality standards and guidelines for product specifications and finish.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tip Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tip Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tip Finishers are responsible for the final finishing touches on manufactured products. They use specialized tools and techniques to ensure that products meet the desired quality standards and specifications. Key job responsibilities include:

1. Inspecting and preparing products

Tip Finishers inspect incoming products to identify any defects or imperfections. They then prepare the products for finishing by cleaning, sanding, or otherwise preparing the surface.

- Ensuring that products meet all quality standards

- Identifying and correcting any defects or imperfections

2. Applying finishing touches

Tip Finishers apply finishing touches to products using a variety of techniques, including painting, staining, polishing, and plating. They also may be responsible for assembling products and packaging them for shipment.

- Applying paint, stain, or other finishing materials to products

- Polishing or buffing products to a high shine

3. Quality control

Tip Finishers are responsible for ensuring that products meet all quality standards. They inspect products throughout the finishing process and make any necessary adjustments to ensure that they meet the desired specifications.

- Inspecting products throughout the finishing process

- Making any necessary adjustments to ensure that products meet all quality standards

4. Maintaining equipment

Tip Finishers are responsible for maintaining the equipment they use. They clean and calibrate equipment regularly and make any necessary repairs to ensure that it is in good working order.

- Cleaning and calibrating equipment

- Making any necessary repairs to equipment

Interview Tips

To ace the interview for a Tip Finisher position, candidates should be prepared to discuss their experience with the following:

1. Finishing techniques

Candidates should be familiar with a variety of finishing techniques, including painting, staining, polishing, and plating. They should also be able to discuss the different materials that can be used for finishing and the pros and cons of each.

- Different finishing techniques

- Materials used for finishing

- Pros and cons of different finishing techniques and materials

2. Quality control

Candidates should be able to demonstrate their understanding of quality control principles and practices. They should be able to discuss how they would ensure that products meet all quality standards and specifications.

- Quality control principles and practices

- How to ensure that products meet all quality standards and specifications

3. Equipment maintenance

Candidates should be able to demonstrate their ability to maintain and repair equipment. They should be able to discuss the different types of equipment that they are familiar with and the maintenance procedures that they have followed.

- Different types of equipment used in finishing

- Maintenance procedures for different types of equipment

4. Safety

Candidates should be aware of the safety hazards associated with finishing and should be able to discuss the safety precautions that they take.

- Safety hazards associated with finishing

- Safety precautions to take when finishing

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tip Finisher, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tip Finisher positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.