Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tire Assembler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

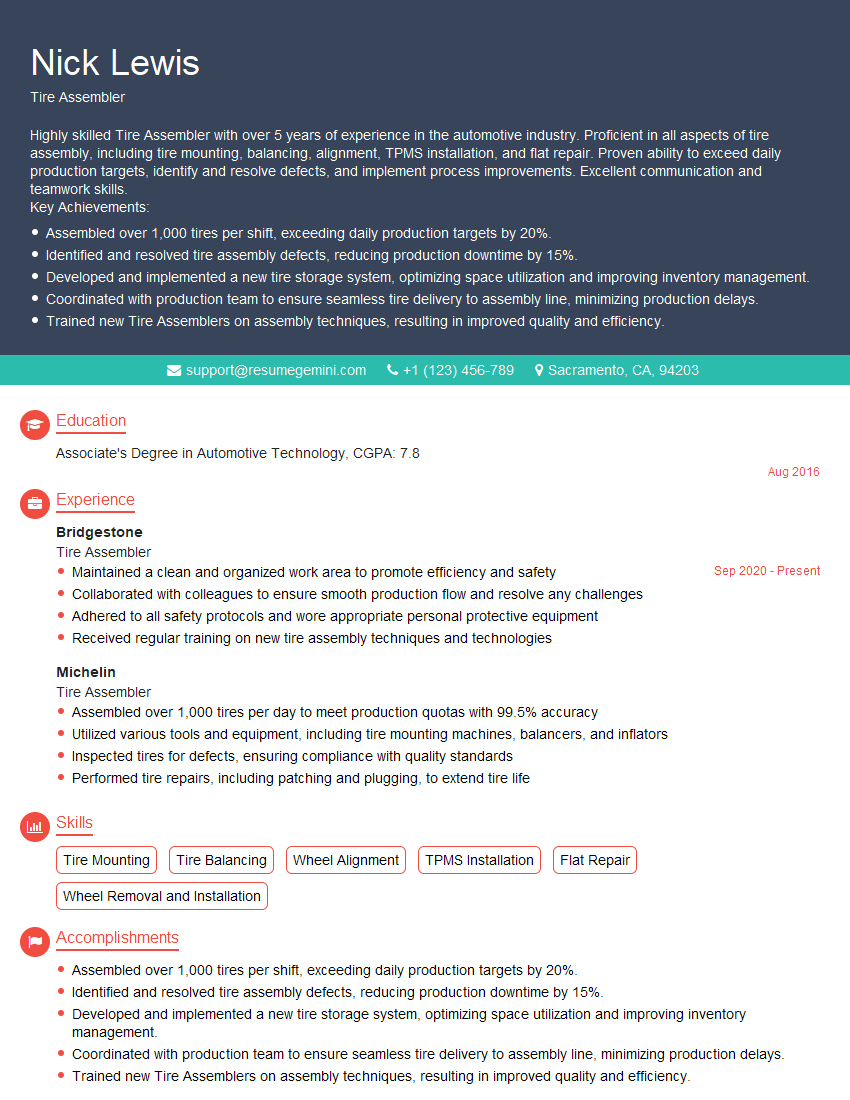

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Assembler

1. Describe the steps involved in assembling a tire onto a wheel rim?

- Inspect the tire and rim for any damage or defects.

- Mount the tire onto the rim using a tire mounting machine.

- Inflate the tire to the specified pressure.

- Balance the tire and wheel assembly.

- Install the tire and wheel assembly onto the vehicle.

2. What are the safety precautions that should be taken when assembling tires?

subheading of the answer

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Never attempt to mount or inflate a tire that is damaged or defective.

- Use a tire mounting machine that is in good working order.

- Inflate tires to the specified pressure using a calibrated tire gauge.

- Never stand in front of a tire when it is being inflated.

subheading of the answer

- Store tires in a dry, cool place away from direct sunlight.

- Never smoke or use open flames near tires.

3. What are the different types of tire balancing machines?

- Static balancers

- Dynamic balancers

- Road force balancers

4. How do you troubleshoot a tire balancing machine?

- Check the machine’s calibration.

- Inspect the machine’s sensors and wiring.

- Check the machine’s software.

- Contact the machine’s manufacturer for assistance.

5. What are the different types of tire repairs?

- Plugs

- Patches

- Vulcanization

6. How do you determine if a tire is repairable?

- The size and location of the puncture.

- The type of tire.

- The age of the tire.

- The condition of the tire.

7. What are the different types of tire pressure monitoring systems (TPMS)?

- Direct TPMS

- Indirect TPMS

8. How do you troubleshoot a TPMS system?

- Check the TPMS sensors.

- Check the TPMS receiver.

- Check the TPMS module.

- Contact the TPMS manufacturer for assistance.

9. What are the different types of tire changing tools?

- Tire irons

- Tire bead breakers

- Tire mounting machines

- Tire balancers

10. How do you safely change a tire?

- Park the vehicle on a level surface.

- Engage the parking brake.

- Loosen the lug nuts on the flat tire.

- Use a jack to raise the vehicle.

- Remove the flat tire.

- Mount the spare tire.

- Tighten the lug nuts.

- Lower the vehicle.

- Torque the lug nuts to the specified specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Assemblers play a crucial role in the automotive industry by ensuring that tires meet safety and performance standards.

1. Inspecting and preparing tires and rims

Check tires for defects or damage before assembling.

- Verify the compatibility of tires and rims.

- Clean and prepare rims for tire mounting.

2. Mounting tires

Mount tires onto rims using specialized equipment.

- Insert valve stems and inflate tires to specified pressure.

- Balance tires to ensure smooth and vibration-free operation.

3. Quality control

Inspect assembled tires for defects or irregularities.

- Check tire pressure and bead seating.

- Verify proper alignment and balance before releasing tires.

4. Equipment maintenance

Maintain and calibrate tire assembly equipment.

- Monitor equipment performance and identify potential issues.

- Perform routine maintenance and repairs to ensure efficient operation.

Interview Tips

To ace your interview for a Tire Assembler position, follow these tips:

1. Research the company and position

Learn about the company’s culture, values, and products before the interview.

- Review the job description carefully and identify key responsibilities.

- Prepare questions to ask the interviewer about the company and the position.

2. Practice your answers to common interview questions

Anticipate questions about your work experience, skills, and why you’re interested in the position.

- Develop clear and concise answers that highlight your strengths and qualifications.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

3. Highlight your technical skills and proficiency

Emphasize your expertise in using tire assembly equipment and following safety protocols.

- Provide examples of your ability to troubleshoot and resolve assembly issues.

- Discuss your understanding of tire specifications and quality control procedures.

4. Demonstrate your attention to detail and commitment to quality

Convey your strong work ethic and meticulous approach to ensuring tire safety.

- Share examples of your attention to detail and commitment to delivering high-quality results.

- Explain how you maintain a clean and organized work environment.

5. Be prepared to discuss your teamwork and communication skills

While Tire Assemblers often work independently, they may also collaborate with other team members.

- Describe your experience working in a team environment.

- Highlight your ability to communicate clearly and effectively with colleagues and customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Assembler interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.