Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tire Beader Maker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

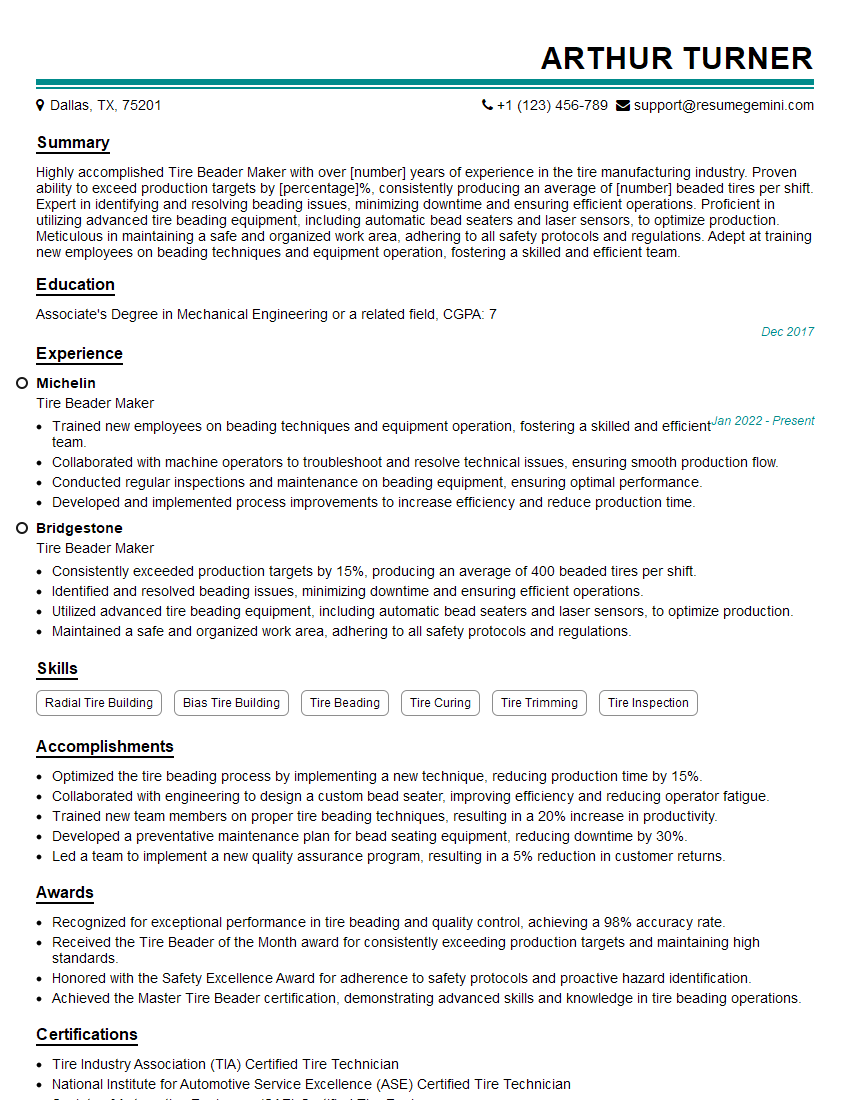

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Beader Maker

1. What are different types of tire beaders and what are their applications?

There are three main types of tire beaders: manual, semi-automatic, and fully automatic.

- Manual tire beaders are operated by hand and are typically used for small tires and wheels.

- Semi-automatic tire beaders are powered by an electric motor and can be used for a wider range of tires and wheels.

- Fully automatic tire beaders are the most expensive and efficient type of tire beaders and can be used for all types of tires and wheels.

2. What are the safety precautions that should be taken when operating a tire beading machine?

Proper Attire

- Always wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Secure loose clothing or jewelry that could get caught in the machine.

Machine Operation

- Ensure the machine is properly grounded and the work area is well-lit.

- Inspect the machine for any damage or loose parts before each use.

Tire Handling

- Never attempt to handle a tire that is too heavy or unwieldy for you to manage safely.

- Use proper lifting techniques to avoid injury.

3. What are the common problems that can occur when using a tire beading machine and how can they be solved?

- Tire bead won’t seat: This can be caused by a variety of factors, such as the tire being too large or too small for the wheel, the bead not being properly seated on the rim, or the bead seater not being properly adjusted.

- Tire bead is damaged: This can be caused by using the wrong size or type of bead seater, or by using too much force when seating the bead.

- Machine is not working properly: This can be caused by a variety of factors, such as a power failure, a hydraulic leak, or a malfunctioning valve.

4. How do you maintain a tire beading machine to ensure its longevity and optimal performance?

- Regularly clean and lubricate the machine according to the manufacturer’s instructions.

- Inspect the machine for any damage or loose parts before each use.

- Store the machine in a dry, clean environment when not in use.

5. What are the different types of tire bead shapes and how do they affect bead seating?

- Straight beads: These are the most common type of tire bead and are found on most passenger car tires.

- Tapered beads: These are found on some high-performance tires and are designed to improve handling and stability.

- Reverse tapered beads: These are found on some off-road tires and are designed to provide better traction in loose soil and mud.

6. How do you determine the correct tire bead seater for a given tire and wheel?

- Size: The size of the bead seater must be compatible with the size of the wheel and tire.

- Type: The type of bead seater must be compatible with the type of tire bead.

- Shape: The shape of the bead seater must match the shape of the tire bead.

7. What are the advantages and disadvantages of using a tire bead sealer?

Advantages

- Helps to seal the tire bead to the rim, preventing leaks.

- Can help to improve tire performance and handling.

- Can help to extend the life of the tire.

Disadvantages

- Can make it more difficult to remove the tire from the wheel.

- Can cause the tire to become unbalanced.

- Can be messy to apply.

8. What are the different types of tire bead lube and how do they affect bead seating?

- Water-based tire bead lube: This is the most common type of tire bead lube and is typically used on passenger car tires.

- Solvent-based tire bead lube: This type of lube is more aggressive than water-based lube and is typically used on high-performance tires and off-road tires.

- Silicone-based tire bead lube: This type of lube is the most slippery and is typically used on tires that are difficult to seat.

9. How do you troubleshoot a tire beading machine that is not seating beads properly?

- Check the tire bead: Make sure that the tire bead is properly seated on the rim and that there are no cuts or tears in the bead.

- Check the bead seater: Make sure that the bead seater is the correct size and type for the tire and wheel.

- Check the machine: Make sure that the machine is properly adjusted and that there are no leaks or other problems.

10. What are the latest trends in tire beading technology?

- Automated tire beading machines: These machines can automatically seat the tire bead on the rim, reducing the risk of injury and improving efficiency.

- Laser-guided tire beading machines: These machines use lasers to guide the bead seater, ensuring a precise and accurate bead seat.

- Touchless tire beading machines: These machines use a combination of air and vacuum to seat the tire bead, eliminating the need for a bead seater.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Beader Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Beader Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Tire Beader Maker, you will play a crucial role in the tire manufacturing process, ensuring the seamless production of high-quality tires. Here are your primary responsibilities:1. Tire Beading

Using specialized beading machines, you will be responsible for inserting the bead wire or ring into the tire casing to form the bead area. This process requires precision and adherence to specifications.

- Operate and maintain beading machines efficiently to insert bead wire or ring into tire casings.

- Ensure proper tension and placement of the bead wire or ring according to established standards.

2. Tire Inspection

You will conduct thorough inspections of beaded tires to verify their quality and compliance with specifications. Your keen eye will detect any defects or irregularities.

- Visually inspect beaded tires for defects such as bead damage, wire breaks, or uneven tension.

- Use measuring tools to ensure that the bead wire or ring is placed within acceptable tolerances.

3. Equipment Maintenance

To maintain optimal production, you will be responsible for cleaning, calibrating, and performing minor repairs on beading machines and other related equipment.

- Clean and lubricate beading machines to ensure smooth operation and prevent breakdowns.

- Calibrate beading machines regularly to maintain accuracy and precision.

4. Production and Quality Control

You will actively monitor the production process to ensure that beaded tires meet quality standards and production targets are achieved.

- Maintain a clean and organized work area to enhance efficiency and productivity.

- Identify and address potential issues in the beading process to minimize defects and improve quality.

Interview Tips

To ace your interview for the Tire Beader Maker position, consider the following tips:1. Research the Company and Industry

Demonstrate your interest and knowledge by researching the company’s history, products, and industry trends. This will show the interviewer that you have taken the time to prepare.

- Visit the company’s website to learn about their mission, values, and recent developments.

- Stay informed about the latest advancements and challenges within the tire manufacturing industry.

2. Highlight Your Skills and Experience

Emphasize your previous experience in tire beading or related manufacturing roles. Quantify your accomplishments using specific examples to demonstrate your capabilities.

- Showcase your proficiency in operating beading machines and inspecting tires for defects.

- Provide examples of how you have maintained equipment and ensured production efficiency in a fast-paced environment.

3. Prepare for Technical Questions

Anticipate technical questions related to tire beading processes, equipment maintenance, and quality control. Practice answering these questions concisely and confidently.

- Review common beading techniques and troubleshooting methods.

- Be familiar with the specifications and tolerances for bead wire insertion and tension.

4. Demonstrate Your Safety Awareness

Emphasize your commitment to safety by highlighting your knowledge of safety protocols specific to tire beading operations.

- Discuss your experience in using personal protective equipment and adhering to safety guidelines.

- Explain how you would prioritize safety in a high-pressure production environment.

5. Practice Your Communication Skills

In the interview, communicate clearly and professionally. Practice articulating your answers and asking relevant questions to show your engagement and comprehension.

- Speak confidently and maintain eye contact during the interview.

- Prepare questions to demonstrate your interest in the position and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Beader Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!