Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tire Buffer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tire Buffer so you can tailor your answers to impress potential employers.

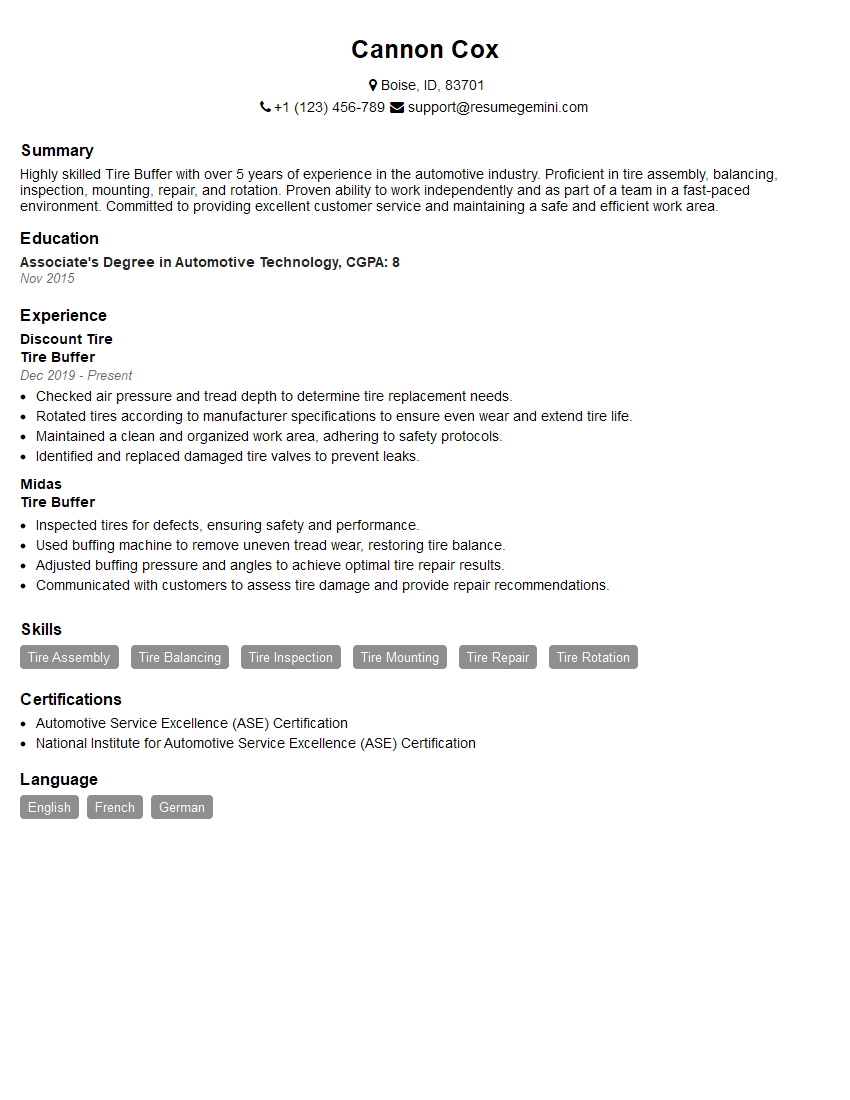

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Buffer

1. What are the different types of tire buffers and their uses?

There are two main types of tire buffers: stationary and mobile. Stationary tire buffers are typically used in tire manufacturing plants and retreading shops, while mobile tire buffers are used for on-site tire repairs and maintenance.

- Stationary tire buffers are large, heavy machines that are bolted to the floor. They are typically equipped with a rotating abrasive wheel that is used to grind down the tire’s surface.

- Mobile tire buffers are smaller, more portable machines that can be used on-site. They are typically equipped with a rotating abrasive wheel or a wire brush that is used to clean and smooth the tire’s surface.

2. What are the safety precautions that should be taken when using a tire buffer?

- Always wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Never operate a tire buffer without proper training.

- Keep the work area clean and free of debris.

- Secure the tire to the machine before starting work.

- Never grind a tire that is not properly inflated.

- Never use a tire buffer on a tire that has been damaged or has a puncture.

3. What are the different types of abrasive wheels that can be used with a tire buffer?

- Coarse abrasive wheels are used to remove large amounts of material from the tire’s surface.

- Medium abrasive wheels are used to smooth the tire’s surface and remove any imperfections.

- Fine abrasive wheels are used to polish the tire’s surface and give it a glossy finish.

4. What is the correct speed to use when operating a tire buffer?

The correct speed to use when operating a tire buffer depends on the type of abrasive wheel being used and the condition of the tire.

- Coarse abrasive wheels should be used at a lower speed to avoid damaging the tire.

- Medium abrasive wheels can be used at a higher speed to smooth the tire’s surface.

- Fine abrasive wheels should be used at a very high speed to polish the tire’s surface.

5. How do you know when a tire is finished being buffed?

A tire is finished being buffed when the surface is smooth and free of any imperfections. You can also check the tire’s surface with your hand. If the tire is smooth to the touch, it is finished being buffed.

6. What are some common problems that can occur when using a tire buffer?

- The abrasive wheel can become clogged with rubber, which can reduce the wheel’s effectiveness.

- The tire can overheat, which can damage the tire and the machine.

- The machine can vibrate excessively, which can make it difficult to control.

7. How do you troubleshoot a tire buffer that is not working properly?

If a tire buffer is not working properly, you should first check the following:

- The power supply.

- The abrasive wheel.

- The machine’s settings.

8. What is the best way to clean and maintain a tire buffer?

- Unplug the machine from the power supply.

- Clean the machine’s exterior with a damp cloth.

- Clean the abrasive wheel with a wire brush.

- Lubricate the machine’s moving parts.

9. What are the different types of tire repair techniques?

- Patching is a temporary repair that involves filling a hole in the tire with a rubber patch.

- Plugging is a permanent repair that involves inserting a rubber plug into a hole in the tire.

- Vulcanizing is a process that involves bonding a new piece of rubber to the damaged area of the tire.

10. What are the different types of tire balancing techniques?

- Static balancing involves adding weight to the tire’s rim to counteract the weight of the tire’s tread.

- Dynamic balancing involves adding weight to the tire’s rim to counteract the weight of the tire’s tread and the tire’s rotation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Buffers are responsible for preparing tires for retreading by buffing off the old tread and other imperfections. Their key job responsibilities include:

1. Tire Preparation

Inspecting tires for any damage or defects

- Removing old valves and other hardware

- Cleaning and prepping tires for buffing

2. Buffing Process

Performing the buffing process on tires using specialized equipment

- Removing old tread patterns and any other imperfections

- Creating a smooth surface for retreading

3. Quality Control

Inspecting buffed tires for proper finish and quality

- Ensuring that tires meet industry standards

- Identifying any issues that may require further processing or repairs

4. Maintenance and Repair

Performing routine maintenance on buffing equipment

- Replacing worn or damaged parts

- Troubleshooting and resolving any equipment malfunctions

Interview Tips

To ace your interview for a Tire Buffer position, consider these tips:

1. Research the Company and Role

Learn about the company’s history, values, and the specific responsibilities of the Tire Buffer role.

- Visit the company website and read any available information

- Connect with current or former employees to gain insights into the work environment

2. Highlight Your Skills and Experience

Emphasize your technical skills, particularly your experience with tire buffing equipment and techniques.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact

- Use action verbs to describe your responsibilities and highlight your contributions

3. Demonstrate Your Attention to Detail

Tire buffing requires precision and attention to detail, so it’s crucial to convey your ability to work meticulously.

- Share examples of your previous work or hobbies that showcase your attention to detail

- Discuss your commitment to quality control and your ability to identify and correct errors

4. Be Prepared to Discuss Safety Procedures

Working with heavy machinery and rotating tires involves potential safety hazards, so employers will want to know your understanding of safety protocols.

- Familiarize yourself with industry-standard safety procedures for tire buffing

- Be prepared to discuss how you would prioritize safety in the workplace

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tire Buffer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.