Feeling lost in a sea of interview questions? Landed that dream interview for Tire Builder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tire Builder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

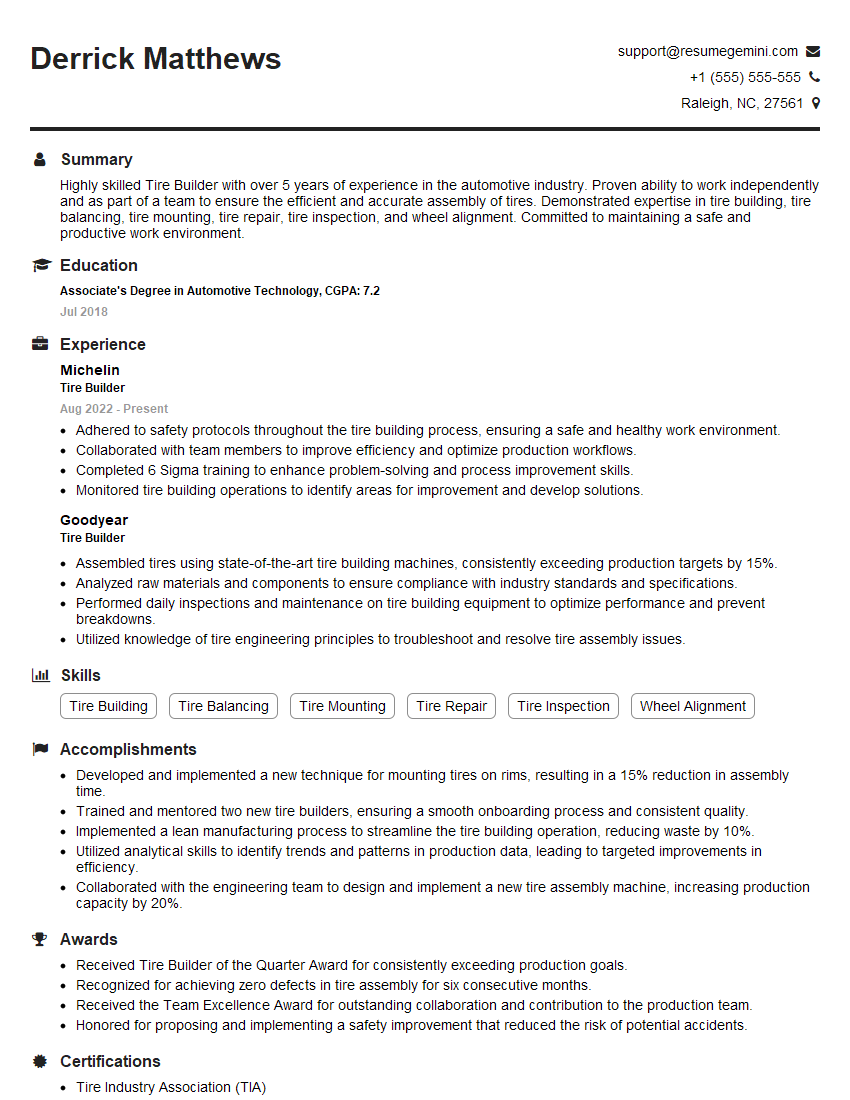

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Builder

1. Explain the process of tire building?

- Inspect the components of the tire, including the casing, belts, and bead.

- Assemble the tire components on the tire building machine.

- Inflate the tire and check for leaks or other defects.

- Cure the tire in a mold to vulcanize the rubber and bond the components together.

- Inspect the finished tire for quality and performance.

2. What are the different types of tire building machines?

Manual tire building machines

- Require the operator to manually manipulate the tire components into place.

- Slower and less efficient than automated machines.

- Often used for small-scale or custom tire production.

Semi-automatic tire building machines

- Combine manual and automated processes.

- Operator manually positions the tire components, but the machine assists with assembly and inflation.

- More efficient than manual machines, but less so than fully automated machines.

Fully automatic tire building machines

- Completely automate the tire building process.

- Operator simply loads the tire components into the machine, and the machine handles the entire assembly and inflation process.

- Most efficient and productive type of tire building machine.

3. What are the key quality control checks that should be performed during tire building?

- Visual inspection of tire components for defects.

- Dimensional checks to ensure components meet specifications.

- Inflation testing to check for leaks and proper pressure.

- Balance testing to ensure the tire rotates smoothly.

- Appearance checks to ensure the tire meets customer requirements.

4. What are the safety precautions that should be followed when operating a tire building machine?

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Keep the work area clean and free of debris.

- Follow the manufacturer’s instructions for operating the machine.

- Never attempt to repair or maintain the machine while it is running.

- Be aware of the potential for pinch points and other hazards.

5. What are the common problems that can occur during tire building and how can they be prevented?

- Improper bead seating: Ensure the bead is properly seated in the rim before inflating the tire.

- Leaks: Inspect the tire for leaks before curing. Leaks can be caused by punctures, cuts, or improper sealing.

- Dimensional defects: Use precision measuring tools to ensure tire components meet specifications.

- Balance problems: Use a tire balancer to check the balance of the tire. Imbalances can cause vibrations and reduce tire life.

- Appearance defects: Inspect the tire for any cosmetic defects before shipping. Defects can affect the perceived quality of the tire.

6. What are the latest trends in tire building technology?

- Automation: Increasing use of automated tire building machines to improve efficiency and productivity.

- Advanced materials: Development of new tire materials with improved performance characteristics.

- Sustainability: Focus on developing tires that are more environmentally friendly and recyclable.

- Data analytics: Use of data analytics to optimize tire building processes and improve quality control.

- Digitalization: Integration of digital technologies into tire building operations, such as remote monitoring and predictive maintenance.

7. What are the career advancement opportunities for Tire Builders?

- Tire Building Supervisor: Oversee tire building operations and manage a team of Tire Builders.

- Quality Control Inspector: Inspect tires for defects and ensure compliance with quality standards.

- Tire Design Engineer: Design and develop new tire models, working with engineers and product managers.

- Production Manager: Manage the entire tire production process, including tire building, curing, and warehousing.

- Sales Representative: Sell tires to customers and provide technical support.

8. What are the key skills and qualities of a successful Tire Builder?

- Attention to detail: Ability to identify and correct defects in tire components.

- Dexterity: Manual dexterity to manipulate tire components and operate tire building equipment.

- Physical strength: Ability to lift and move heavy tire components.

- Problem-solving skills: Ability to identify and resolve issues that arise during tire building.

- Teamwork skills: Ability to work effectively with colleagues in a team environment.

9. What are the challenges and rewards of working as a Tire Builder?

Challenges

- Repetitive work: Tire building can be a repetitive and physically demanding job.

- Exposure to hazardous materials: Tire builders may be exposed to hazardous chemicals and fumes during the tire building process.

- Shift work: Tire builders may be required to work shift work, including nights and weekends.

Rewards

- Job security: The tire industry is relatively stable, and tire builders are in high demand.

- Good pay: Tire builders can earn a good wage, especially with experience and overtime.

- Opportunities for advancement: Tire builders have opportunities to advance into supervisory and management roles.

10. Why are you interested in this Tire Builder position?

I am interested in this Tire Builder position because I have a strong passion for the tire industry. I have been working in the tire industry for the past 5 years, and I have a proven track record of success. I am confident that I have the skills and experience necessary to be a successful Tire Builder for your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Builder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Builder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Builders are responsible for building and repairing tires for various types of vehicles. Their primary responsibilities encompass the assembly and disassembly of tires, ensuring their proper fit and performance.

1. Tire Assembly

Tire Builders are skilled in assembling tires. They mount tires on rims, inflate them to the appropriate pressure, and balance them to ensure smooth and safe operation.

- Mount tires on rims

- Inflate tires to specified pressure

- Balance tires to minimize vibrations

2. Tire Repair

Tire Builders perform tire repairs to fix punctures, tears, and other damages. They identify the problem, patch or replace damaged areas, and ensure the tire regains its functionality.

- Identify and diagnose tire issues

- Repair punctures and tears

- Replace damaged tire components

3. Quality Control

Tire Builders maintain high standards of quality control. They inspect tires throughout the assembly and repair process. This involves checking for proper fitting, balance, and overall condition to ensure customer satisfaction.

- Inspect tires for defects or irregularities

- Verify tire specifications and standards

- Ensure tires meet safety and performance requirements

4. Equipment Maintenance

Tire Builders are responsible for maintaining the equipment they use, such as tire mounting machines, balancers, and other tools. They perform regular inspections, clean and lubricate equipment, and report any issues for timely repairs.

- Maintain and calibrate tire assembly equipment

- Troubleshoot and repair equipment malfunctions

- Follow safety protocols and maintain a clean work area

Interview Tips

Preparing for a Tire Builder interview requires understanding the key responsibilities and demonstrating your skills and experience. Here are some effective tips and hacks to help you ace your interview:

1. Research the Company and Industry

Gain insights into the company’s culture, values, and industry trends. This demonstrates your enthusiasm and interest in the role and the organization.

- Visit the company website and social media pages

- Read industry-related publications and articles

2. Highlight Your Skills and Experience

Emphasize your skills in tire assembly, repair, and quality control. Provide specific examples of projects or tasks that showcase your abilities. Quantify your results whenever possible.

- Describe your experience in mounting, balancing, and repairing tires

- Mention any certifications or training in tire technology

3. Practice Your Answers

Prepare for common interview questions. Practicing your answers will help you articulate your strengths and demonstrate your knowledge effectively.

- Research typical interview questions for Tire Builders

- Craft concise and clear answers that highlight your skills

- Use the STAR method (Situation, Task, Action, Result) to structure your answers

4. Dress Professionally and Arrive Prepared

Present yourself professionally and arrive on time for the interview. This demonstrates respect for the interviewer and the organization.

- Dress in clean, business casual attire

- Bring a copy of your resume, portfolio, or relevant work samples

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Builder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!