Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tire Cord Weaver interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tire Cord Weaver so you can tailor your answers to impress potential employers.

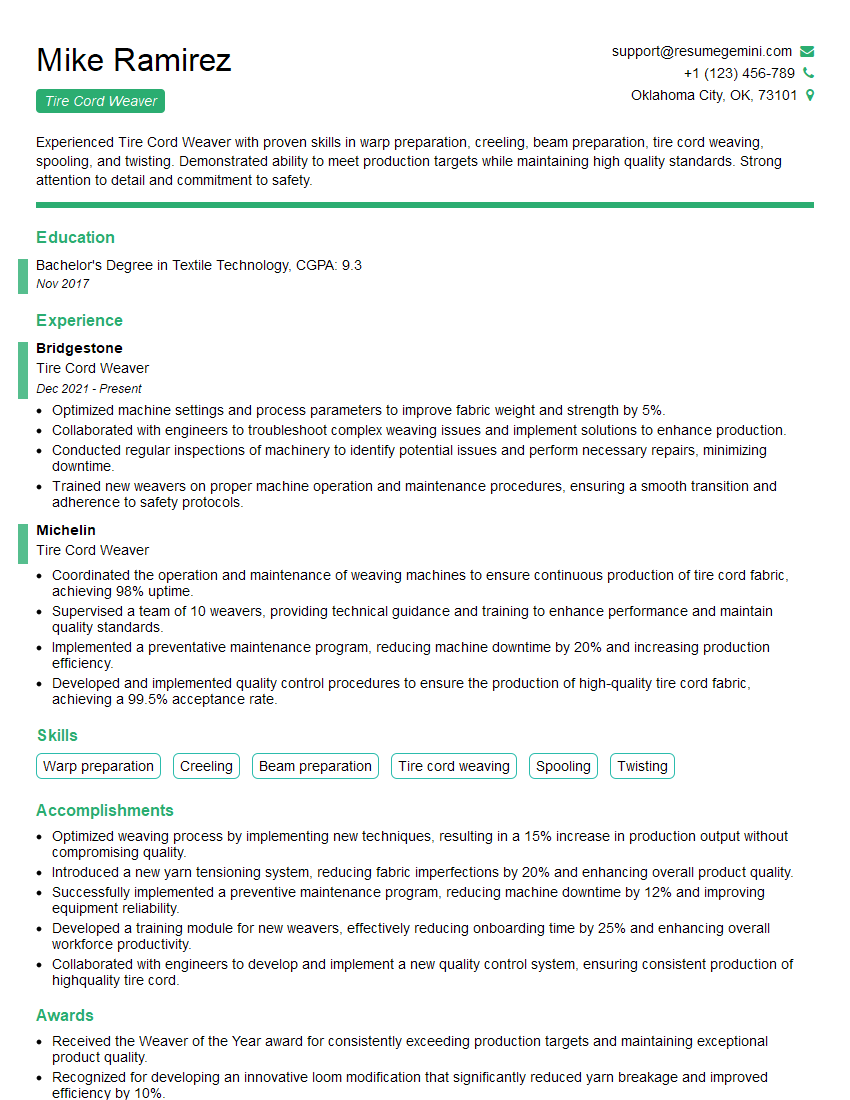

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Cord Weaver

1. Describe the different types of tire cord fabrics and their applications?

Sure, here are the different types of tire cord fabrics and their applications:

- Nylon tire cord fabric: Nylon is a synthetic fiber that is strong, durable, and has good elasticity. Nylon tire cord fabric is used in the construction of radial tires, which are used in passenger cars, light trucks, and SUVs.

- Polyester tire cord fabric: Polyester is a synthetic fiber that is strong, durable, and has low stretch. Polyester tire cord fabric is used in the construction of bias tires, which are used in heavy trucks and buses.

- Steel tire cord fabric: Steel is a metal that is strong, durable, and has high stiffness. Steel tire cord fabric is used in the construction of radial tires for high-performance vehicles, such as sports cars and race cars.

2. Explain the process of weaving tire cord fabric?

Weaving Preparation

- Preparing the yarn: The yarn is first prepared by winding it onto a creel or beam.

- Warping: The yarn is then warped onto a loom, which is a machine that holds the yarn in place while it is being woven.

Weaving Process

- Shedding: The warp yarns are separated into two layers, called sheds.

- Filling insertion: The weft yarn is inserted between the sheds.

- Beating up: The weft yarn is beaten into place using a reed.

Finishing

- The woven fabric is inspected for defects.

- The fabric is then treated with a sizing agent to improve its strength and durability.

- The fabric is finally calendared to give it a smooth finish.

3. What are the key factors that affect the quality of tire cord fabric?

The key factors that affect the quality of tire cord fabric include:

- The type of fiber used: The type of fiber used will determine the strength, durability, and elasticity of the fabric.

- The yarn count: The yarn count refers to the number of yarns per inch in the fabric. A higher yarn count will result in a stronger and more durable fabric.

- The weave pattern: The weave pattern will determine the appearance and performance of the fabric.

- The finishing process: The finishing process will improve the strength, durability, and appearance of the fabric.

4. How do you troubleshoot common problems that occur during the weaving of tire cord fabric?

Common problems that occur during the weaving of tire cord fabric include:

- Yarn breakage: Yarn breakage can be caused by a variety of factors, such as the use of weak yarn, improper tension, or damage to the loom.

- Fabric defects: Fabric defects can be caused by a variety of factors, such as improper weaving, contamination, or damage to the fabric.

- Machine downtime: Machine downtime can be caused by a variety of factors, such as mechanical problems, electrical problems, or operator error.

To troubleshoot these problems, it is important to identify the root cause of the problem and then take steps to correct it.

5. What are the latest trends in tire cord fabric manufacturing?

The latest trends in tire cord fabric manufacturing include:

- The use of new materials: New materials, such as high-strength fibers and nanocomposites, are being used to develop stronger and more durable tire cord fabrics.

- The development of new weaving technologies: New weaving technologies, such as 3D weaving, are being used to develop tire cord fabrics with improved performance.

- The use of automation: Automation is being used to improve the efficiency and quality of tire cord fabric manufacturing.

6. How do you stay up-to-date on the latest developments in tire cord fabric manufacturing?

I stay up-to-date on the latest developments in tire cord fabric manufacturing by:

- Reading industry publications: I read industry publications, such as Tire Technology International and Rubber World, to learn about the latest news and developments in the tire cord fabric industry.

- Attending industry conferences: I attend industry conferences, such as the International Tire Expo and the Tire Technology Conference, to learn about the latest technologies and trends in the tire cord fabric industry.

- Networking with industry professionals: I network with industry professionals, such as engineers, researchers, and suppliers, to learn about the latest developments in the tire cord fabric industry.

7. What are the challenges facing the tire cord fabric industry?

The tire cord fabric industry is facing a number of challenges, including:

- The increasing cost of raw materials: The cost of raw materials, such as nylon and polyester, has been increasing in recent years, which is putting pressure on tire cord fabric manufacturers.

- The competition from low-cost countries: Tire cord fabric manufacturers in low-cost countries, such as China and India, are able to produce tire cord fabric at a lower cost than manufacturers in developed countries.

- The changing demand for tire cord fabric: The demand for tire cord fabric is changing as the automotive industry moves towards the production of electric vehicles.

8. What are the opportunities for the tire cord fabric industry?

The tire cord fabric industry has a number of opportunities, including:

- The growing demand for high-performance tires: The demand for high-performance tires is growing as consumers demand tires that provide better handling, traction, and fuel efficiency.

- The development of new markets: New markets for tire cord fabric are emerging, such as the market for tires for electric vehicles.

- The development of new technologies: New technologies, such as 3D weaving, are being developed to improve the performance of tire cord fabric.

9. How do you see the tire cord fabric industry evolving in the future?

I believe that the tire cord fabric industry will continue to evolve in the future. I expect to see the following trends:

- The use of new materials: New materials, such as high-strength fibers and nanocomposites, will be used to develop stronger and more durable tire cord fabrics.

- The development of new weaving technologies: New weaving technologies, such as 3D weaving, will be used to develop tire cord fabrics with improved performance.

- The use of automation: Automation will be used to improve the efficiency and quality of tire cord fabric manufacturing.

- The development of new markets: New markets for tire cord fabric will emerge, such as the market for tires for electric vehicles.

10. What are your career goals?

My career goals are to:

- Become a leading expert in the tire cord fabric industry.

- Develop new and innovative tire cord fabrics.

- Help the tire cord fabric industry to grow and prosper.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Cord Weaver.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Cord Weaver‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Cord Weavers are responsible for operating and maintaining looms that weave tire cord, a high-tensile fabric used in the reinforcement of tires. They ensure that the looms are running smoothly and that the tire cord is produced according to specifications.

1. Loom Operation

- Setup and operate looms to weave tire cord

- Monitor looms for proper operation and make adjustments as needed

- Inspect tire cord for defects and make repairs as necessary

2. Loom Maintenance

- Perform routine maintenance on looms, including cleaning, lubrication, and adjustments

- Troubleshoot and repair loom problems

- Maintain a clean and safe work area

3. Quality Control

- Inspect tire cord for defects and make repairs as necessary

- Monitor the quality of the tire cord produced

- Maintain records of loom operation and tire cord production

4. Other Duties

- Follow safety procedures and wear appropriate safety gear

- May train new employees

- May supervise other Tire Cord Weavers

Interview Tips

Preparing for a Tire Cord Weaver interview can help you make a great impression on the hiring manager and increase your chances of getting the job. Here are some tips to help you prepare:

1. Research the Company and Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the job. You can find this information on the company’s website, Glassdoor, or other online resources.

2. Practice Your Answers

Once you have a good understanding of the company and position, you can start practicing your answers to interview questions. Common interview questions for Tire Cord Weavers include:

- Tell me about your experience operating and maintaining looms.

- What are some of the challenges you have faced in your previous role as a Tire Cord Weaver?

- How do you ensure that the tire cord you produce meets quality standards?

When practicing your answers, try to be as specific as possible and use examples from your own experience. This will help you stand out from other candidates and demonstrate your qualifications for the job.

3. Be Prepared to Talk About Your Safety Experience

Safety is a top priority in the textile industry, so be prepared to talk about your safety experience during the interview. This could include discussing your experience with OSHA regulations, safety procedures, and any safety training you have received.

4. Dress Professionally

First impressions matter, so dress professionally for your interview. This means wearing clean, pressed clothes and avoiding casual attire. You should also arrive on time for your interview and be polite and respectful to the interviewer.

5. Be Enthusiastic and Positive

Finally, be enthusiastic and positive during your interview. This will show the interviewer that you are genuinely interested in the position and that you are confident in your abilities. Remember, the interviewer is looking for someone who is passionate about their work and who will be a valuable asset to their team.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Cord Weaver interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.