Feeling lost in a sea of interview questions? Landed that dream interview for Tire Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tire Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

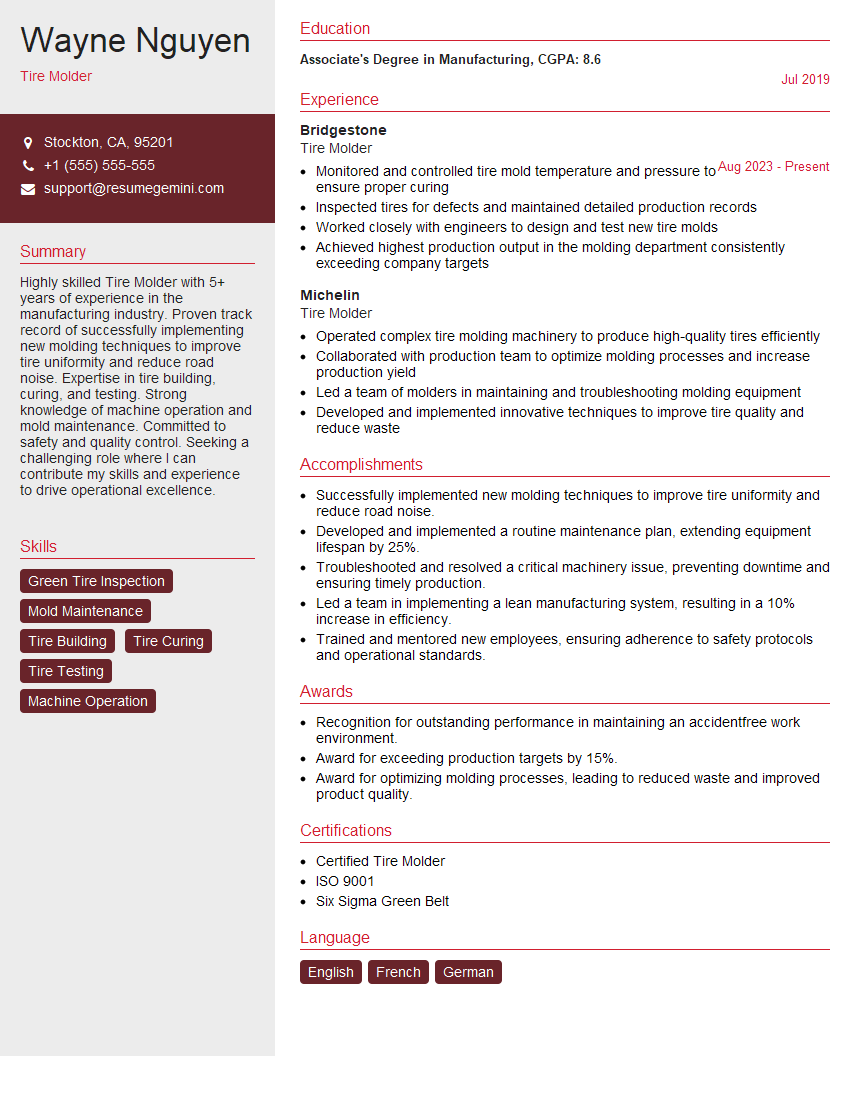

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Molder

1. Describe the process of tire molding in detail.

The process of tire molding involves several crucial steps to produce high-quality tires. Here’s a detailed description:

- Compound preparation: Raw rubber is mixed with other ingredients, such as carbon black and silica, to create the tire compound according to the desired specifications.

- Extrusion: The rubber compound is heated and extruded through dies to form different components like sidewalls, treads, and inner liners.

- Component assembly: The extruded components are assembled on a tire building machine to create the green tire, which is the uncured tire.

- Molding: The green tire is placed in a heated mold, which applies pressure and heat to cure the rubber and give the tire its final shape and pattern.

- Cooling: After curing, the tire is cooled to room temperature to ensure proper rubber properties.

- Inspection: The finished tires undergo rigorous quality inspections to meet safety and performance standards.

2. Explain the importance of temperature control during tire molding.

Precision and Uniformity

- Temperature control ensures that the rubber compound cures uniformly throughout the tire, resulting in consistent material properties and performance.

- Optimizing temperature prevents over- or under-curing, which can lead to defects and reduced tire lifespan.

Quality and Durability

- Proper temperature control minimizes thermal stress and prevents premature aging of the rubber, extending the tire’s durability.

- Controlled curing ensures that the tire meets the desired hardness, strength, and grip characteristics.

3. Discuss the different methods used for molding tires.

There are two primary methods used for molding tires:

- Compression molding: This method uses a heated mold that applies pressure to the green tire from above and below, compressing it into the desired shape.

- Injection molding: In this method, the rubber compound is injected into a heated mold cavity, where it cures and takes the shape of the mold.

4. What are the key parameters to consider when optimizing the tire molding process?

- Mold design: The shape and surface texture of the mold significantly impact the final tire characteristics.

- Temperature and pressure: Controlling these parameters ensures proper curing and desired rubber properties.

- Mold maintenance: Regular cleaning and maintenance of the mold prevent contamination and ensure consistent tire quality.

- Compound formulation: The composition of the rubber compound affects its curing behavior and performance.

- Cooling rate: Controlling the cooling process optimizes the tire’s physical properties and reduces residual stresses.

5. How do you troubleshoot common defects in molded tires?

To troubleshoot common defects, I follow a systematic approach:

- Identify the defect: Determine the specific defect, such as voids, blisters, or uneven tread wear.

- Trace the cause: Analyze the molding process, materials, and equipment to identify potential causes.

- Isolate the issue: Conduct tests or experiments to narrow down the root cause.

- Implement corrective actions: Based on the identified cause, make necessary adjustments to the molding parameters, compound formulation, or equipment.

- Monitor and verify: Observe the results after implementing corrective actions to ensure defect elimination.

6. Describe the role of quality control in tire molding.

- Ensuring product quality: Quality control measures monitor and maintain tire specifications, preventing defects and ensuring product reliability.

- Process optimization: By analyzing quality data, areas for process improvement can be identified, leading to increased efficiency.

- Customer satisfaction: Consistent and high-quality tires enhance customer satisfaction and build brand reputation.

- Compliance with industry standards: Quality control ensures that tires meet regulatory requirements and industry standards.

7. How do you stay updated with the latest advancements in tire molding technology?

To stay informed, I actively engage in the following:

- Industry events and conferences: Attending industry events provides opportunities to learn about new technologies, network with experts, and stay abreast of market trends.

- Technical journals and publications: Reading specialized publications and research papers keeps me updated on advancements in molding processes, materials, and equipment.

- Training and certification programs: Participating in training programs and obtaining certifications demonstrates my commitment to staying current with industry best practices.

- Collaboration with suppliers and partners: Building relationships with suppliers and industry partners allows for information exchange and insights into emerging technologies.

8. What are the safety precautions that must be observed during tire molding?

- Proper PPE: Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs, is essential.

- Machine safety: Ensuring that molding machines are well-maintained and operated according to safety protocols.

- Chemical handling: Following proper procedures for handling and storing chemicals used in the molding process.

- Temperature monitoring: Regularly monitoring mold temperatures to prevent overheating and potential hazards.

- Emergency preparedness: Having knowledge of emergency procedures and evacuation plans in case of an incident.

9. Describe the importance of following standard operating procedures (SOPs) in tire molding.

- Consistency and quality: SOPs ensure that molding processes are carried out consistently, leading to uniform tire quality.

- Safety: Adhering to SOPs minimizes risks and maintains a safe working environment.

- Efficiency: Well-defined SOPs improve efficiency by streamlining processes and reducing errors.

- Training and onboarding: SOPs provide a clear reference for training new employees and onboarding them faster.

- Compliance: Following SOPs demonstrates adherence to industry regulations and quality standards.

10. How do you manage and prioritize multiple tasks effectively in a fast-paced tire molding environment?

To effectively manage and prioritize multiple tasks in a fast-paced environment, I apply the following strategies:

- Task prioritization: I assess the urgency and importance of each task to determine its priority level.

- Time management techniques: I utilize time management tools like to-do lists, calendars, and task management apps to stay organized and track progress.

- Delegation: When necessary, I delegate tasks to capable team members to distribute the workload efficiently.

- Communication: I maintain open communication with colleagues and supervisors to ensure task coordination and avoid overlaps.

- Continuous improvement: I regularly evaluate my task management strategies and seek opportunities to streamline processes and improve efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire Molders are responsible for operating tire molding machines to produce tires. They ensure that the tires meet the required specifications and quality standards.

1. Machine Operation

Tire Molders are responsible for operating tire molding machines. They must be able to set up and operate the machines safely and efficiently.

- Setting up and operating tire molding machines

- Monitoring the machines during operation

- Troubleshooting and repairing any problems with the machines

2. Tire Production

Tire Molders are responsible for producing tires that meet the required specifications and quality standards. They must be able to follow instructions and work independently.

- Following instructions to produce tires

- Inspecting tires for defects

- Packaging and shipping tires

3. Quality Control

Tire Molders are responsible for ensuring that the tires they produce meet the required quality standards. They must be able to identify and correct any defects.

- Identifying and correcting defects in tires

- Maintaining records of tire production and quality

- Working with other departments to improve tire quality

4. Safety

Tire Molders must follow all safety regulations and procedures. They must be able to work in a safe manner and avoid accidents.

- Following all safety regulations and procedures

- Working in a safe manner

- Avoiding accidents

Interview Tips

Preparing for an interview can be daunting, but it is important to put your best foot forward. Here are a few tips to help you ace your interview for a Tire Molder position:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website

- Read industry publications

- Talk to people who work for the company

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

- Practice answering common interview questions

- Get feedback from a friend or family member

- Use online resources to find sample answers

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

- Dress professionally

- Arrive on time

- Be respectful of the interviewer’s time

4. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Show the interviewer that you are excited about the opportunity to work for the company and that you are confident in your abilities.

- Be enthusiastic about the position

- Have a positive attitude

- Show the interviewer that you are confident in your abilities

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tire Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.