Are you gearing up for a career in Tire Vulcanizer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tire Vulcanizer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

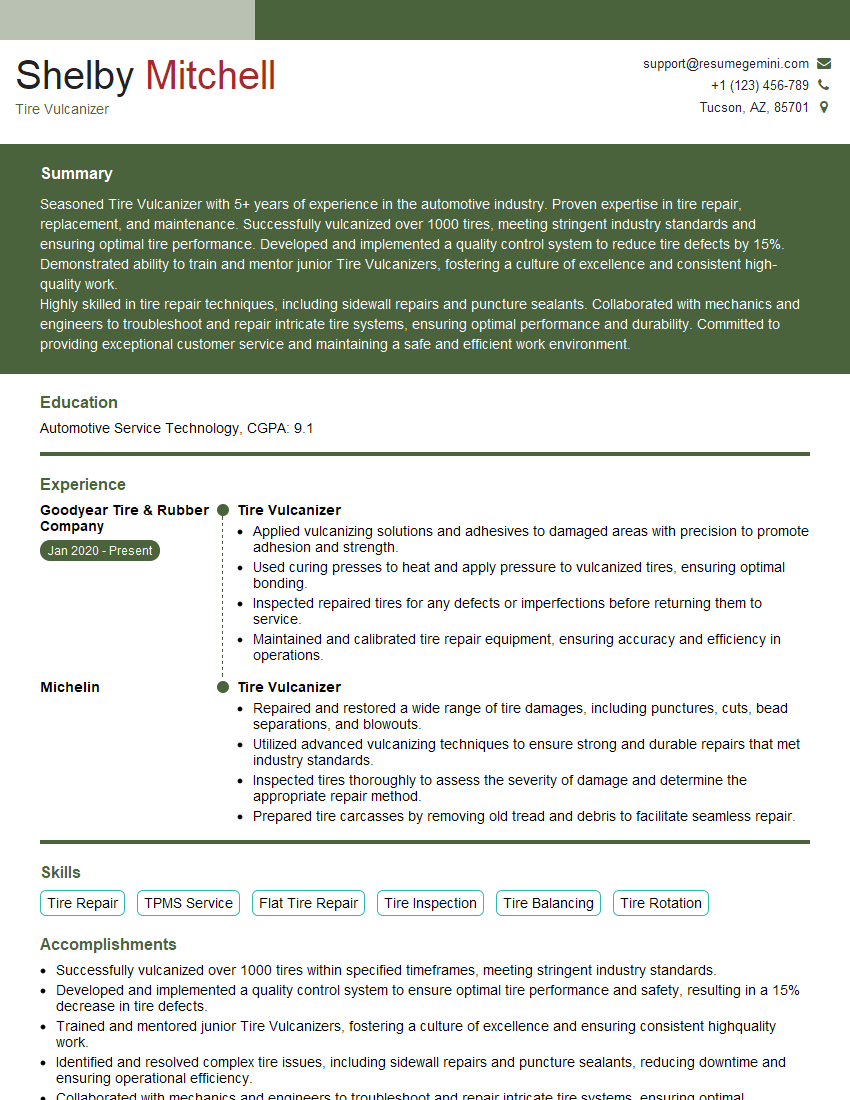

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tire Vulcanizer

1. What are the different types of tire vulcanizing techniques?

Tire vulcanizing is a process of heating raw rubber to change its physical properties. There are two main types of tire vulcanizing techniques: hot vulcanizing and cold vulcanizing.

- Hot vulcanizing is the most common type of vulcanizing. It involves heating the raw rubber to a temperature of around 150 degrees Celsius (300 degrees Fahrenheit) for a period of time. This causes the sulfur in the rubber to react with the rubber molecules, forming cross-links that give the rubber its strength and elasticity.

- Cold vulcanizing is a newer type of vulcanizing that does not require heat. Instead, it uses a chemical reaction to cross-link the rubber molecules. Cold vulcanizing is often used for small repairs or for vulcanizing rubber in place, such as on a tire.

2. What are the different types of tire vulcanizing machines?

- Floor-mounted vulcanizing machines are the most common type of vulcanizing machine. They are typically used for large tires, such as those on semi-trucks or buses.

- Benchtop vulcanizing machines are smaller and more portable than floor-mounted machines. They are typically used for smaller tires, such as those on cars or motorcycles.

- Handheld vulcanizing machines are the most portable type of vulcanizing machine. They are typically used for small repairs or for vulcanizing rubber in place, such as on a tire.

3. What are the steps involved in vulcanizing a tire?

The steps involved in vulcanizing a tire are as follows:

- Prepare the tire by cleaning it and removing any debris.

- Apply a layer of vulcanizing cement to the tire.

- Place the tire in the vulcanizing machine and close the lid.

- Set the temperature and time according to the manufacturer’s instructions.

- Start the vulcanizing process.

- Once the vulcanizing process is complete, remove the tire from the machine and allow it to cool.

4. What are the safety precautions that should be taken when vulcanizing tires?

The following safety precautions should be taken when vulcanizing tires:

- Always wear appropriate safety gear, such as gloves, safety glasses, and a respirator.

- Never operate a vulcanizing machine without proper training.

- Always follow the manufacturer’s instructions for operating the vulcanizing machine.

- Never leave a vulcanizing machine unattended.

- Always allow the tire to cool completely before handling it.

5. What are the common problems that can occur during tire vulcanizing?

- Under-vulcanization occurs when the tire is not heated to a high enough temperature or for a long enough period of time. This can result in a weak tire that is prone to failure.

- Over-vulcanization occurs when the tire is heated to too high a temperature or for too long a period of time. This can result in a hard, brittle tire that is also prone to failure.

- Blisters can occur when air or moisture is trapped in the tire during vulcanizing. These blisters can weaken the tire and cause it to fail.

- Cracks can occur when the tire is not properly prepared before vulcanizing. These cracks can also weaken the tire and cause it to fail.

6. What are the different types of tire repairs that can be performed with a vulcanizing machine?

- Plugs are used to repair small punctures in tires.

- Patches are used to repair larger punctures or cuts in tires.

- Section repairs are used to repair large sections of a tire that have been damaged.

- Tread repairs are used to repair worn or damaged tread on a tire.

7. What are the different types of rubber that can be vulcanized?

- Natural rubber is the most common type of rubber used in tires.

- Synthetic rubber is a man-made rubber that is often used in tires for its improved performance and durability.

- Reclaimed rubber is a type of rubber that is made from recycled tires.

8. What are the different types of vulcanizing compounds?

- Sulfur is the most common vulcanizing compound. It is used to cross-link the rubber molecules, giving the rubber its strength and elasticity.

- Peroxides are another type of vulcanizing compound that is often used in conjunction with sulfur. Peroxides help to improve the cross-linking process and can also increase the strength and durability of the rubber.

- Resins are a type of vulcanizing compound that is often used to improve the adhesion between the rubber and the tire.

9. What are the different factors that affect the vulcanization process?

- Temperature is the most important factor that affects the vulcanization process. The higher the temperature, the faster the vulcanization process will occur.

- Time is another important factor that affects the vulcanization process. The longer the rubber is heated, the more complete the vulcanization process will be.

- Pressure can also affect the vulcanization process. The higher the pressure, the more dense the vulcanized rubber will be.

- The type of rubber being vulcanized can also affect the vulcanization process. Different types of rubber have different vulcanization characteristics.

10. What are the different applications of vulcanized rubber?

- Vulcanized rubber is used in a wide variety of applications, including:

- Tires

- Hoses

- Belts

- Seals

- Gaskets

- Insulation

- Footwear

- Medical devices

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tire Vulcanizer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tire Vulcanizer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tire vulcanizers play a crucial role in the automotive industry, ensuring the safety and durability of tires. Their responsibilities encompass a wide range of tasks, from repairing and replacing damaged tires to performing preventive maintenance. Key job responsibilities include:

1. Tire Repair and Replacement

Vulcanizers are responsible for diagnosing and repairing tire damage caused by punctures, blowouts, or wear and tear. They use specialized equipment and techniques to patch, plug, or replace damaged tire components, ensuring the tire’s integrity and functionality.

- Inspect tires for damage and determine repair or replacement needs

- Repair punctures, tears, and other tire damages using a variety of methods

- Replace damaged or worn-out tires with new ones

2. Tire Inspection and Maintenance

Regular tire inspection and maintenance is essential for preventing tire failures and ensuring optimal performance. Tire vulcanizers inspect tires for signs of wear and tear, including tread depth, sidewall damage, and uneven wear. They also perform tire balancing and alignment to improve handling, stability, and tire life.

- Inspect tires for wear, damage, and other issues

- Perform tire balancing and alignment to ensure proper vehicle handling

- Recommend tire maintenance and replacement based on inspection findings

3. Equipment Operation and Maintenance

Tire vulcanizers rely on a range of specialized equipment, including tire changers, balancers, and alignment machines. They are responsible for operating and maintaining this equipment, ensuring its accurate and efficient functioning. Additionally, they are responsible for maintaining a clean and organized work area.

- Operate tire changers, balancers, and alignment machines

- Maintain equipment to ensure proper functioning and safety

- Keep work area clean and organized for efficient operations

4. Customer Service and Safety

Tire vulcanizers interact with customers to understand their needs and provide prompt and courteous service. They also ensure the safety of customers and themselves by following proper safety protocols and utilizing personal protective equipment.

- Provide excellent customer service and address customer concerns

- Follow safety protocols and use personal protective equipment

- Maintain a professional and courteous demeanor

Interview Tips

Preparation is key to ace any job interview. Here are some tips and hacks for candidates seeking a Tire Vulcanizer position:

1. Research the Company and Role

Thoroughly research the company you’re applying to and the specific Tire Vulcanizer position. This will give you a clear understanding of the company’s culture, values, and the responsibilities of the role. You’ll be able to tailor your answers and demonstrate your alignment with the company’s goals.

- Visit the company’s website and social media pages

- Read industry news and articles to stay informed about the company’s initiatives

- Connect with current or former employees on LinkedIn

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your work. For example, instead of simply stating “I repaired tires,” you could say “I repaired over 100 tires per month, reducing downtime and improving safety.”

- Review the job description and identify the key skills and qualifications required

- Provide specific examples of how you’ve used these skills in previous roles

- Quantify your accomplishments to demonstrate your value

3. Practice Commonly Asked Questions

There are certain questions that are commonly asked in Tire Vulcanizer interviews. Prepare answers to these questions in advance to build confidence and deliver clear and concise responses. Some common questions include:

- Tell me about your experience in tire repair and replacement.

- Describe your knowledge of tire inspection and maintenance procedures.

- How do you ensure the safety of yourself and customers while working with tire equipment?

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that are specific to the company or the role. This shows that you’re genuinely interested in the position and have taken the time to learn more about the company.

- What are the company’s plans for growth and innovation in the tire industry?

- Can you describe the company’s safety culture and how it’s implemented in the workplace?

- What opportunities are there for professional development and advancement within the company?

5. Dress Professionally and Arrive on Time

First impressions matter. Make sure to dress professionally for the interview, even if it’s a casual work environment. Arrive on time to show respect for the interviewer’s time. Being punctual and well-dressed demonstrates your professionalism and respect for the company.

- Choose clothing that is clean, pressed, and appropriate for a professional setting

- Arrive at the interview location 10-15 minutes early

- Maintain good posture and make eye contact during the interview

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tire Vulcanizer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.