Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tobacco Blender position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

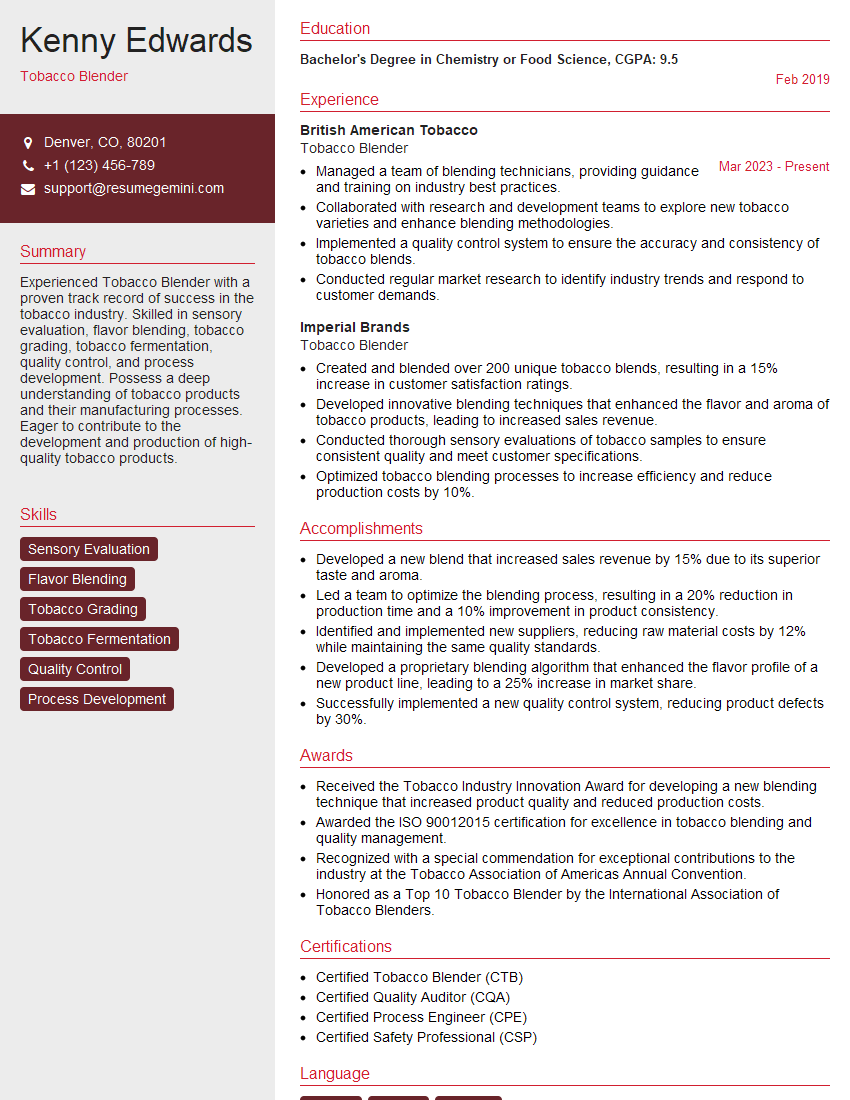

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tobacco Blender

1. What is the role of nicotine in tobacco blending?

Nicotine is a key component in tobacco blending as it affects the taste, aroma, and strength of the finished product. It also influences the addictive properties of tobacco.

- Nicotine levels vary depending on the tobacco variety and growing conditions, and blenders adjust these levels to meet specific product requirements.

- Nicotine content is closely regulated by governments and manufacturers to ensure compliance with safety standards and consumer preferences.

2. Explain the different blending techniques used in tobacco production.

Casing

- Casing involves adding water to tobacco to increase its moisture content and make it more flexible for blending.

- The amount of water added depends on the desired moisture level and the tobacco’s natural moisture content.

Topping

- Topping involves adding flavorings, aromas, or other ingredients to tobacco to enhance its taste and aroma.

- The type and amount of toppings used depend on the desired flavor profile and market preferences.

Blending

- Blending involves mixing different tobacco varieties and grades to create a desired flavor, aroma, and strength.

- Blenders consider factors such as nicotine content, sweetness, acidity, and aroma when blending different tobaccos.

3. How do you ensure the consistency and quality of blended tobacco products?

Ensuring consistency and quality in blended tobacco products requires a comprehensive approach that includes:

- Raw Material Control: Establishing quality standards for tobacco varieties, growing practices, and harvesting techniques.

- Blending Process Standardization: Defining clear and repeatable blending procedures to ensure consistent flavor, aroma, and nicotine content.

- Quality Testing: Implementing rigorous testing methods to assess nicotine content, moisture levels, aroma, and other quality parameters.

- Equipment Calibration and Maintenance: Regularly calibrating and maintaining blending equipment to ensure accurate measurements and consistent performance.

- Quality Control Team: Establishing a dedicated quality control team to monitor the blending process, evaluate product quality, and identify any deviations from standards.

4. What are the common challenges you encounter in tobacco blending and how do you overcome them?

- Variability in Raw Materials: Natural variations in tobacco quality and flavor profiles can affect blending outcomes. To overcome this, blenders carefully select and assess tobacco varieties, blend different grades, and use standardized blending techniques.

- Meeting Consumer Preferences: Keeping up with evolving consumer tastes and preferences is crucial. Blenders conduct market research, analyze sales data, and collaborate with marketing teams to create blends that meet market demands.

- Regulatory Compliance: Tobacco blending must adhere to strict government regulations. Blenders stay updated on regulatory changes, implement quality control systems, and work closely with regulatory agencies to ensure compliance.

- Production Efficiency: Optimizing blending processes to meet production targets while maintaining quality is a challenge. Blenders use automation, streamline workflows, and continuously improve blending procedures to enhance efficiency.

5. Describe your approach to creating innovative tobacco blends.

- Market Research: Conducting thorough market research to identify emerging trends, consumer preferences, and competitive products.

- Experimentation: Experimenting with different tobacco varieties, flavorings, and blending techniques to create unique and captivating blends.

- Collaboration: Collaborating with other experts, such as flavorists and marketers, to gather insights and create innovative blends that meet market needs.

- Sensory Evaluation: Conducting sensory evaluations to assess the flavor, aroma, and strength of new blends and gather feedback from consumers and experts.

6. How do you stay updated on the latest advancements in tobacco blending technology?

- Industry Events: Attending industry conferences, exhibitions, and workshops to learn about new technologies and trends.

- Trade Publications: Reading industry publications and online resources to stay informed about advancements in blending equipment, techniques, and ingredients.

- Collaboration: Networking with other professionals in the field and sharing knowledge and experiences to stay up-to-date on industry developments.

- Research and Development: Engaging in research and development projects to explore new blending techniques and improve existing processes.

7. What is your understanding of the health implications of tobacco blending?

Tobacco blending plays a significant role in influencing the health effects of tobacco products. As a Tobacco Blender, I am aware of the following:

- Nicotine Content: Nicotine is a highly addictive substance that can lead to health issues, including cardiovascular disease and cancer. Blenders carefully control nicotine levels to minimize their negative effects.

- Flavorings: Certain flavorings added to tobacco products can mask the harsh taste of tobacco and make them more appealing to consumers. However, some flavorings may contain harmful chemicals.

- Additives: Additives used in tobacco blending can affect the burning properties and overall health effects of tobacco products.

- Product Warnings and Disclosures: Tobacco products must carry clear warnings about their health risks. Blenders play a role in ensuring that these warnings are accurate and effectively communicated to consumers.

8. How do you ensure that tobacco blends meet regulatory standards and consumer expectations?

- Regulatory Compliance: Blenders adhere to all applicable laws and regulations governing tobacco blending, including those related to nicotine content, flavorings, and additives.

- Quality Control: Implementing comprehensive quality control measures to ensure that blends meet internal standards and consumer expectations for flavor, aroma, and strength.

- Consumer Testing: Conducting consumer testing to evaluate the acceptability and appeal of new blends and gather feedback for product improvements.

- Market Surveillance: Monitoring market trends and consumer preferences to adapt blends and ensure their alignment with evolving regulatory requirements.

9. What is your approach to managing the costs associated with tobacco blending?

- Raw Material Sourcing: Establishing relationships with reliable suppliers to secure high-quality raw materials at competitive prices.

- Efficient Blending Processes: Optimizing blending techniques to minimize waste and maximize yield.

- Inventory Management: Effectively managing tobacco inventory to reduce spoilage and ensure optimal stock levels.

- Waste Reduction: Implementing waste reduction strategies, such as recycling and reusing materials, to minimize production costs.

10. How do you handle customer feedback and complaints regarding tobacco blends?

- Responsive Customer Service: Establishing a dedicated customer service channel to promptly address customer inquiries and complaints.

- Feedback Analysis: Analyzing customer feedback to identify patterns, trends, and recurring issues with blends.

- Product Improvement: Using customer feedback to drive product improvement and address any concerns or dissatisfaction with blends.

- Communication: Communicating with customers in a timely and professional manner to resolve complaints and build trust.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tobacco Blender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tobacco Blender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tobacco Blenders are responsible for creating various tobacco blends used in cigarettes, cigars, and other tobacco products. They use their knowledge of tobacco varieties, flavors, and aromas to develop new and innovative blends that meet consumer demand. The key responsibilities of a Tobacco Blender include:

1. Tobacco Selection and Blending

Tobacco Blenders select and blend different varieties of tobacco to create unique flavors and aromas. They consider factors such as the origin, curing method, and nicotine content of the tobacco.

- Choosing and mixing various tobacco types to achieve desired flavor profiles

- Adjusting the blend’s strength, aroma, and taste based on market trends and consumer preferences

2. Quality Control and Testing

Tobacco Blenders ensure that the tobacco blends meet quality standards. They conduct tests to check the blend’s moisture content, nicotine levels, and aroma. They also monitor the manufacturing process to ensure that the blend is produced consistently.

- Monitoring tobacco quality and ensuring adherence to specifications

- Conducting chemical and sensory evaluations to assess blend properties and make necessary adjustments

3. Research and Development

Tobacco Blenders stay updated on the latest tobacco varieties and blending techniques. They conduct research to develop new and improved blends that meet the evolving demands of the market. They also work closely with product development teams to create new tobacco products.

- Exploring new tobacco varieties and flavors to enhance product offerings

- Collaborating with research scientists and product development teams to create innovative blends

4. Sensory Evaluation and Feedback

Tobacco Blenders conduct sensory evaluations to assess the quality of their blends. They use their expertise to identify and adjust any sensory defects. They also gather feedback from consumers to understand their preferences and make necessary changes to the blend.

- Conducting taste tests and sensory evaluations to determine blend quality

- Incorporating consumer feedback and market research into blend development

Interview Tips

Preparing for an interview as a Tobacco Blender requires thorough research and a well-structured approach. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Before the interview, take the time to research the tobacco company and the industry as a whole. This will give you a good understanding of the company’s products, market position, and industry trends. You should also familiarize yourself with the specific role and responsibilities of a Tobacco Blender within the company.

- Visit the company’s website, read industry publications, and attend industry events

- Identify the company’s key competitors and their market share

2. Highlight Your Technical Skills and Experience

Tobacco Blenders are highly skilled professionals with a deep understanding of tobacco varieties, flavors, and aromas. During the interview, be sure to highlight your technical skills and experience in tobacco blending. Provide specific examples of your work and how you have contributed to the success of previous tobacco products.

- Quantify your accomplishments and provide specific examples of your blend development process

- Discuss your knowledge of different tobacco varieties and their flavor profiles

3. Showcase Your Knowledge of Quality Control and Testing

Tobacco Blenders play a critical role in ensuring the quality of tobacco products. In the interview, emphasize your knowledge of quality control and testing procedures. Explain how you monitor the manufacturing process and conduct sensory evaluations to ensure that the blend meets quality standards.

- Describe your experience with tobacco testing and analysis

- Discuss your understanding of industry quality standards and regulations

4. Demonstrate Your Passion for Tobacco Blending

Tobacco Blenders are passionate about their work. During the interview, show your enthusiasm for tobacco blending and your desire to create innovative and successful products. Explain what drives you and why you are excited about the opportunity to work as a Tobacco Blender.

- Share your experiences with tobacco blending and how it has shaped your career

- Discuss your ideas for new and improved tobacco blends

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tobacco Blender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!