Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tobacco Primer Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

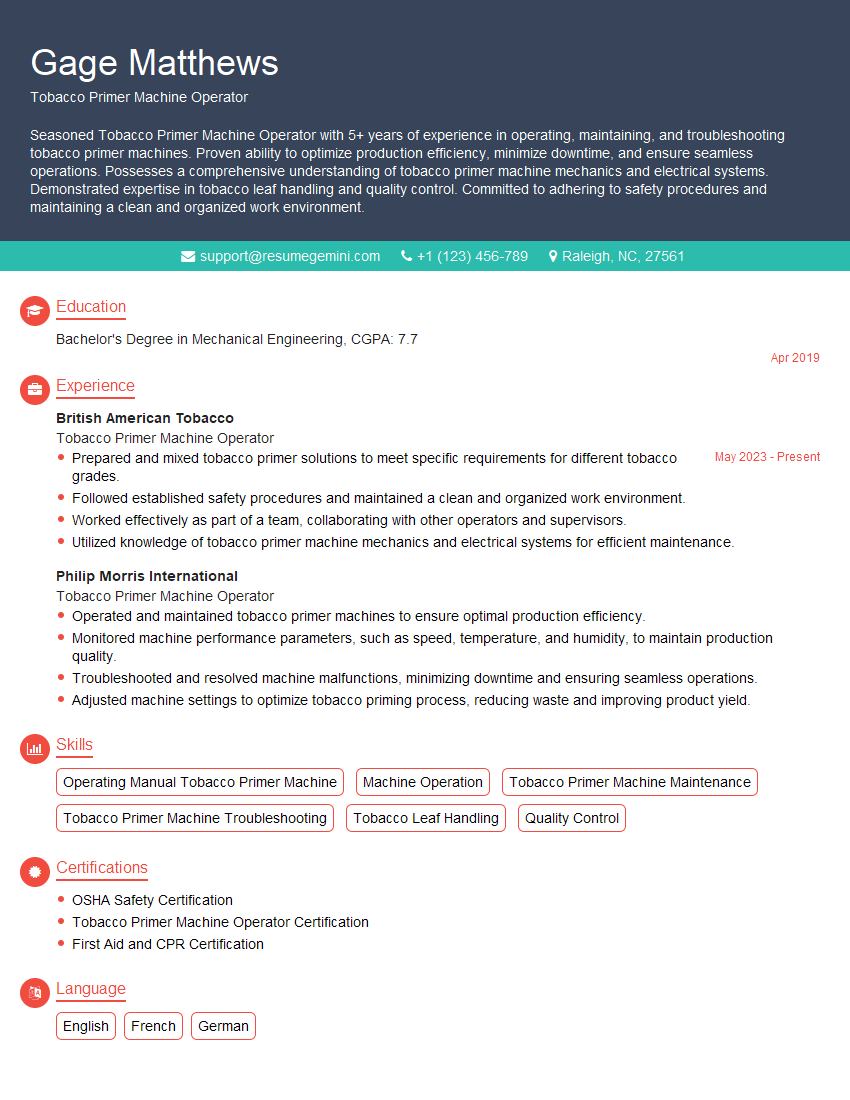

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tobacco Primer Machine Operator

1. How do you verify the proper calibration of the tobacco primer machine?

- Verify the accuracy of the weighing system by regularly checking the weight of a known sample against the machine’s reading.

- Inspect the primer applicator to ensure correct spacing and alignment of the primers.

- Monitor the compressed air system to ensure proper pressure for the primer applicator.

- Check the tension of the belts and chains to prevent slippage and maintain optimal machine performance.

2. What are the critical parameters to monitor during tobacco priming machine operation?

Tobacco Leaf Moisture Content

- Maintain the moisture content of tobacco leaves within specified limits to prevent tearing or crumbling.

Primer Mixture Quality

- Ensure the primer mixture has the correct consistency, viscosity, and adhesion properties for effective bonding.

Application Rate and Coverage

- Monitor the primer application rate to achieve uniform coverage without over-application or missed areas.

Machine Temperature

- Control the temperature of the primer application system to prevent premature drying or clumping.

3. Describe the steps involved in troubleshooting a tobacco primer machine.

- Identify the problem by observing the machine’s behavior and checking for error messages.

- Review the machine’s manual and consult with experienced operators for potential solutions.

- Inspect the machine’s components, such as the primer applicator, belts, sensors, and electrical connections.

- Clean and lubricate the machine as necessary to remove any debris or blockages.

- Adjust settings or replace components if required to resolve the issue.

4. How do you minimize the production of waste in the tobacco priming process?

- Optimize the primer application rate to avoid over-application and dripping.

- Monitor the machine’s calibration regularly to ensure accurate dosage and avoid wastage due to incorrect settings.

- Inspect the tobacco leaves carefully before priming to identify and remove damaged or unsuitable leaves.

- Implement proper storage and handling practices to prevent tobacco leaf damage and reduce the need for re-priming.

5. How do you ensure the safety of yourself and others while operating a tobacco primer machine?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a mask.

- Follow established safety protocols and procedures for machine operation and maintenance.

- Maintain a clean and well-organized work area to prevent slips and falls.

- Be aware of the machine’s moving parts and avoid contact during operation.

- Report any potential hazards or unsafe conditions to supervisors or maintenance personnel immediately.

6. Can you describe the different types of tobacco primers and their respective advantages?

- Acrylic-based primers: Provide good adhesion and resistance to moisture, making them suitable for outdoor applications.

- Water-based primers: Environmentally friendly and easy to apply, but may require additional coats for durability.

- Oil-based primers: Highly durable and resistant to solvents, but can be more difficult to apply and have a longer drying time.

- Shellac-based primers: Offer excellent sealing properties and protect against insects, but can be more expensive than other options.

7. What factors influence the choice of primer for a specific tobacco product?

- Type of tobacco leaf: Different tobacco varieties have different surface characteristics and require primers with varying adhesion properties.

- Application method: The primer’s viscosity and flow properties should be suitable for the chosen application method (e.g., brushing, spraying).

- Environmental conditions: The durability and moisture resistance of the primer must match the intended use and storage conditions of the tobacco product.

- Cost and availability: The cost and availability of different primers should be considered in relation to the desired product quality.

8. How do you monitor the quality of tobacco primers to ensure consistency and effectiveness?

- Visual inspection: Examine the primer for any signs of separation, clumping, or contamination.

- Viscosity measurement: Use a viscometer to ensure the primer has the correct consistency for application.

- Adhesion test: Apply the primer to a sample tobacco leaf and check its adhesion after drying.

- Performance testing: Conduct field trials or laboratory tests to evaluate the primer’s effectiveness in protecting tobacco leaves.

9. How do you troubleshoot common issues related to tobacco primer application?

- Poor adhesion: Check the primer’s viscosity, surface preparation, and application technique.

- Clumping or separation: Investigate the primer’s storage conditions, mixing methods, and application equipment.

- Discoloration or staining: Identify the source of contamination or incompatibility between the primer and tobacco leaf.

- Slow drying: Adjust the application rate, temperature, or humidity levels to optimize drying time.

10. How do you stay up-to-date on the latest advancements and best practices in tobacco priming?

- Attend industry conferences and workshops: Network with experts and learn about new technologies and techniques.

- Read trade publications and research papers: Stay informed about the latest findings and industry trends.

- Seek training and certification programs: Enhance your skills and knowledge through formal training opportunities.

- Collaborate with other professionals: Exchange ideas and experiences with colleagues in the field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tobacco Primer Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tobacco Primer Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Tobacco Primer Machine Operator is responsible for the efficient operation and maintenance of tobacco primer machines. Their key job responsibilities include:1. Operating Tobacco Primer Machines

Operate tobacco primer machines to apply a primer solution to tobacco seeds, ensuring optimal germination and growth.

- Set up and adjust primer machine settings according to specifications and seed variety.

- Monitor the priming process and make adjustments as needed to ensure proper application and coverage.

2. Machine Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting on tobacco primer machines to ensure optimal performance.

- Clean and lubricate machine components regularly to prevent malfunctions.

- Identify and resolve operational issues promptly, minimizing downtime.

3. Monitoring and Quality Control

Monitor the quality of the primed seeds and adjust machine settings accordingly to meet specifications.

- Inspect primed seeds for uniformity, coverage, and any defects.

- Document priming parameters and monitor seed germination rates to ensure quality standards are met.

4. Health and Safety Compliance

Adhere to all health and safety regulations related to the handling of tobacco seeds and chemicals used in the priming process.

- Wear appropriate personal protective equipment (PPE) when operating machines or handling chemicals.

- Dispose of waste materials properly and follow established environmental regulations.

Interview Tips

To ace an interview for a Tobacco Primer Machine Operator position, candidates should prepare thoroughly and demonstrate the following:1. Technical Knowledge and Experience:

Emphasize your experience with operating tobacco primer machines, including knowledge of machine settings, troubleshooting techniques, and maintenance procedures.

2. Attention to Detail:

Highlight your ability to pay close attention to detail and maintain consistent seed quality. Provide examples of how you have ensured accuracy and met quality standards in previous roles.

3. Problem-Solving Skills:

Demonstrate your ability to troubleshoot mechanical issues and resolve operational problems effectively. Share examples of how you have identified and resolved machine malfunctions in the past.

4. Quality Assurance Mindset:

Emphasize your commitment to quality and your ability to monitor and maintain seed quality. Discuss your methods for inspecting seeds and ensuring they meet specifications.

5. Health and Safety Awareness:

Highlight your understanding of the health and safety regulations related to the tobacco industry and your commitment to following them. Discuss your experience with handling chemicals and hazardous materials safely.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tobacco Primer Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!