Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tobacco Stemmer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tobacco Stemmer so you can tailor your answers to impress potential employers.

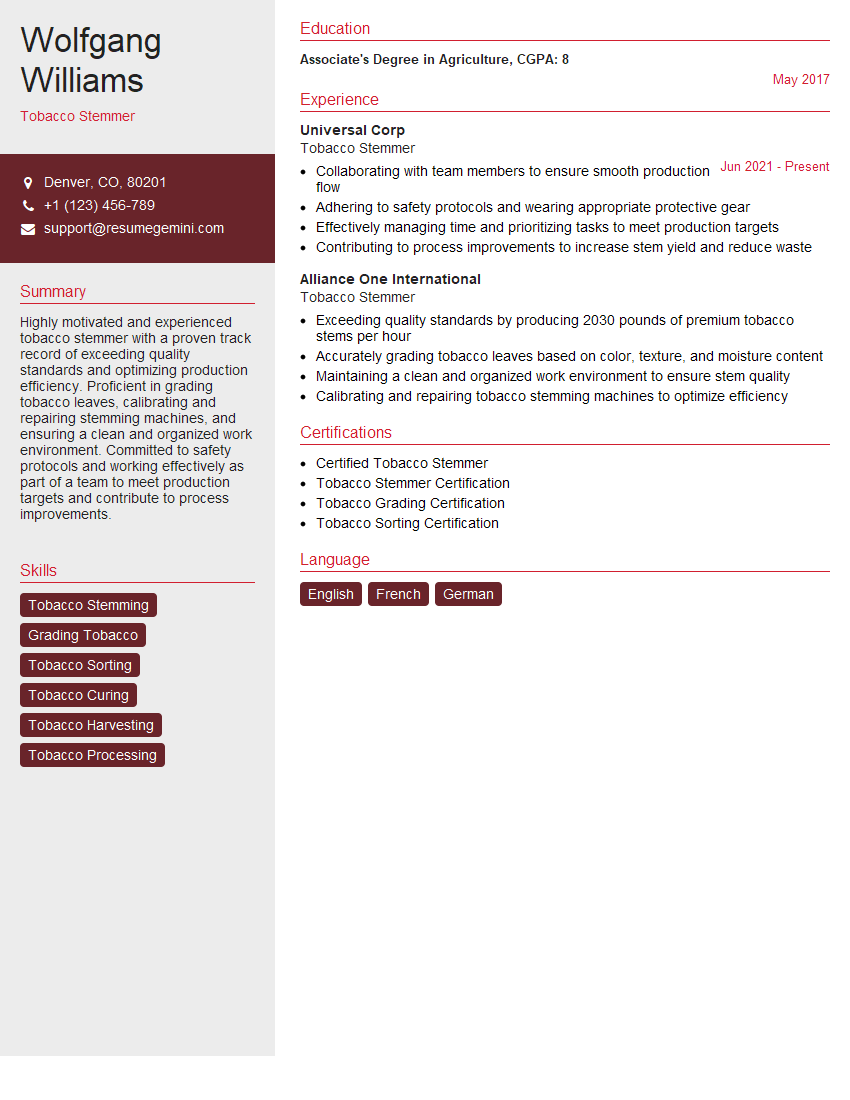

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tobacco Stemmer

1. How do you ensure the quality of the tobacco stems during the stemming process?

- Inspect the raw tobacco for any imperfections or damage.

- Calibrate and maintain the stemming machine regularly to ensure optimal performance.

- Monitor the stemming process closely and adjust settings as needed to achieve desired results.

2. What are the common problems faced during tobacco stemming and how do you troubleshoot them?

Machine-related problems

- Clogged or damaged blades: Replace or clean blades as necessary.

- Misalignment of components: Adjust or replace components to ensure proper alignment.

Tobacco-related problems

- Wet or moist tobacco: Dry the tobacco before stemming to avoid clumping.

- Overripe or brittle tobacco: Adjust machine settings to reduce breakage.

Environmental problems

- High humidity: Control humidity levels within the stemming area to prevent moisture regain.

- Dust and debris: Implement proper ventilation and cleaning measures to minimize contaminants.

3. What is the ideal moisture content for tobacco stemming and how do you achieve it?

- The optimal moisture content for tobacco stemming is typically between 12% and 15%.

- Air curing or drying the tobacco can reduce moisture content.

- Using humidifiers or misters can increase moisture content if necessary.

4. What safety precautions are essential when operating a tobacco stemming machine?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and earplugs.

- Follow proper lockout/tagout procedures before servicing the machine.

- Keep the work area clean and free of debris to prevent accidents.

- Be aware of pinch points and moving parts to avoid injury.

5. How do you adjust the stemming machine to accommodate different types and grades of tobacco?

- Adjust the blade speed and spacing to suit the thickness and texture of the tobacco.

- Modify the feed rate and tension to optimize the separation and removal of stems.

- Calibrate the machine’s sensors to accurately detect and remove stems.

6. What maintenance procedures are required to ensure the longevity and efficiency of the tobacco stemming machine?

- Regular cleaning and lubrication of all moving parts.

- Inspection and tightening of belts, chains, and other mechanical components.

- Calibration and testing of sensors and control systems.

- Replacement of worn or damaged parts as necessary.

7. How do you manage waste generated during the tobacco stemming process?

- Collect and dispose of tobacco stems and other waste materials in a designated area.

- Adhere to environmental regulations regarding waste disposal.

- Explore potential uses or recycling opportunities for certain waste products.

8. How do you maintain quality control standards in the tobacco stemming process?

- Establish and adhere to specific quality parameters for the final stemmed tobacco.

- Inspect the stemmed tobacco regularly to ensure it meets the desired specifications.

- Document and track quality control measures to ensure consistency.

9. What is your approach to working in a team environment and collaborating with colleagues?

- Communicate effectively, share information, and support team members.

- Contribute to a positive and cooperative work atmosphere.

- Respect and value the diversity of perspectives and skills within the team.

10. How do you stay up-to-date with the latest advancements and best practices in tobacco stemming technology?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Network with other tobacco stemming professionals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tobacco Stemmer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tobacco Stemmer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tobacco Stemmers are responsible for removing the stems and other foreign matter from tobacco leaves. They also inspect the leaves for any signs damage or disease. The job requires a high level of attention to detail and manual dexterity.

1. Remove stems and foreign matter from tobacco leaves

This is the primary responsibility of a Tobacco Stemmer. They use a variety of tools, such as knives and scissors, to remove the stems and any other foreign matter from the leaves. They must be careful not to damage the leaves in the process.

2. Inspect tobacco leaves for damage and disease

Tobacco Stemmers also inspect the leaves for any signs damage or disease. They are looking for things like holes, tears, and discoloration. If they find any damaged leaves, they remove them from the batch.

3. Sort tobacco leaves by grade

Once the leaves have been stemmed and inspected, they are sorted by grade. The grade of the leaf is determined by its size, color, and texture. Tobacco Stemmers use a variety of methods to sort the leaves, such as visual inspection and mechanical sorting.

4. Package and store tobacco leaves

Once the leaves have been sorted, they are packaged and stored. Tobacco Stemmers use a variety of packaging methods, such as boxes, bags, and barrels. They must ensure that the leaves are stored in a cool, dry place to prevent them from deteriorating.

Interview Tips

Here are a few tips to help you prepare for your interview for a Tobacco Stemmer position:

1. Research the company

Before you go to your interview, take some time to learn more about the company. This will show the interviewer that you are interested in the position and that you have taken the time to prepare.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience

The interviewer will want to know about your experience working as a Tobacco Stemmer. Be prepared to talk about your skills and abilities, as well as any specific accomplishments you have achieved.

4. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This shows the interviewer that you are serious about the position and that you are a good fit for the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tobacco Stemmer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!