Are you gearing up for an interview for a Toilet Products Molder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Toilet Products Molder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

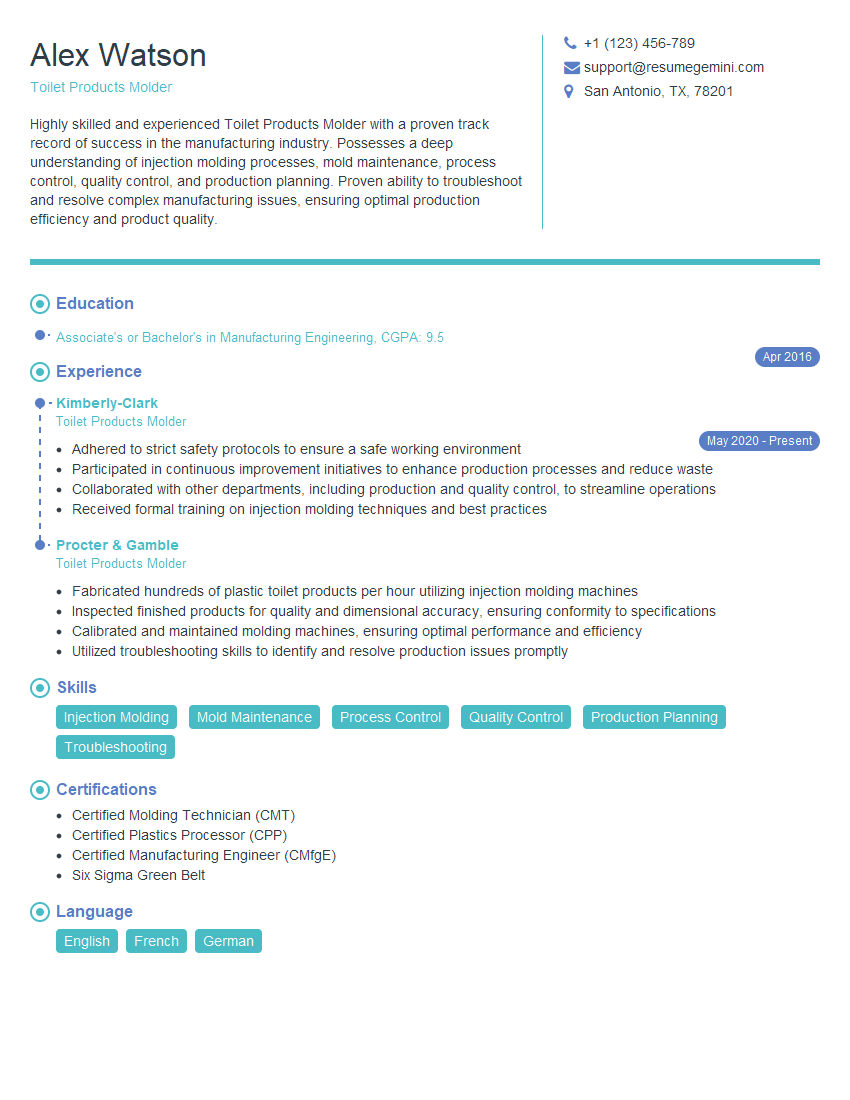

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Toilet Products Molder

1. What is the process of toilet products molding?

The process of toilet products molding involves several steps:

- Mold design: Designing the mold that will shape the toilet product.

- Raw material selection: Choosing the appropriate materials for the toilet product, such as plastic or ceramic.

- Molding: Injecting or pressing the raw material into the mold to create the desired shape.

- Cooling: Allowing the molded product to cool and solidify.

- Finishing: Performing any necessary finishing operations, such as trimming, polishing, or glazing.

2. What are the different types of molding machines used in the toilet products industry?

Injection molding machines

- Uses high pressure to inject molten plastic into a mold.

- Produces high-volume, complex-shaped parts.

Compression molding machines

- Uses heat and pressure to compress a molding compound into a mold.

- Suitable for thermosetting plastics and rubber.

Transfer molding machines

- Similar to injection molding, but the molten plastic is transferred from a separate pot into the mold.

- Produces parts with intricate shapes and high dimensional accuracy.

3. What are the key factors that affect the quality of molded toilet products?

- Mold design: Proper design ensures optimal flow of materials and prevents defects.

- Material selection: The properties of the material impact the strength, durability, and aesthetics of the product.

- Molding conditions: Parameters such as temperature, pressure, and cooling time affect the quality of the molded part.

- Finishing processes: Additional steps like trimming, polishing, or glazing can enhance the appearance and performance of the product.

4. How do you ensure dimensional accuracy in molded toilet products?

- Precise mold design: Using advanced software and tooling techniques.

- Optimal molding conditions: Controlling parameters like temperature and pressure to minimize warpage or shrinkage.

- Dimensional inspection: Regularly checking molded parts against specifications using measuring equipment.

- Mold maintenance: Regularly inspecting and repairing molds to prevent wear or damage.

5. How do you identify and troubleshoot defects in molded toilet products?

- Visual inspection: Examining products for any visible flaws or irregularities.

- Dimensional testing: Using measuring tools to check for deviations from specifications.

- Material testing: Analyzing the material properties to ensure they meet standards.

- Process analysis: Reviewing molding conditions and identifying potential causes of defects.

6. What are the safety precautions that must be followed when working with toilet products molding machines?

- Proper training: Operators should be trained on safe operating procedures.

- Protective gear: Wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Machine guarding: Ensure that all moving parts and potential hazards are properly guarded.

- Emergency procedures: Know the emergency stop procedures and evacuation routes.

7. What are the latest advancements in toilet products molding technology?

- Automated molding machines: Reduce manual labor and improve efficiency.

- 3D printing: Enables rapid prototyping and production of complex shapes.

- Smart molding: Sensors and data analytics optimize molding processes and reduce defects.

- Sustainable materials: Environmentally friendly materials are being developed for toilet products.

8. How do you stay updated with the latest trends and best practices in the toilet products molding industry?

- Industry conferences and exhibitions: Attend events to learn about new technologies and developments.

- Trade publications and online resources: Read industry-specific magazines and websites.

- Networking with professionals: Connect with experts and exchange knowledge.

- Continuing education: Participate in training programs or workshops.

9. What are your strengths and weaknesses as a Toilet Products Molder?

-

Strengths:

- Proficient in operating various molding machines.

- Expertise in mold design and maintenance.

- Excellent problem-solving and troubleshooting skills.

- Strong attention to detail and quality. Weaknesses:

- Limited experience in working with certain specialized materials.

- Working in a fast-paced environment can sometimes be challenging.

10. How do you handle working under pressure and meeting deadlines?

- Prioritize tasks: Identify the most critical tasks and focus on completing them first.

- Delegate effectively: If possible, delegate tasks to others to distribute the workload.

- Time management: Use tools like scheduling and to-do lists to manage time efficiently.

- Stay organized: Maintain a clean and organized workspace to minimize distractions.

- Communicate regularly: Keep stakeholders informed about progress and any potential delays.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Toilet Products Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Toilet Products Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Toilet Products Molder is responsible for operating machinery that molds and shapes various toilet products such as toilet bowls, tanks, and seats. They work in a fast-paced, production-oriented environment, ensuring that products meet quality standards and production targets.

1. Molding and Shaping

The primary responsibility of a Toilet Products Molder is to operate molding machines, which use heat and pressure to shape and form toilet products.

- Set up and operate molding machinery according to specifications.

- Monitor the molding process to ensure that products are formed correctly.

- Inspect molded products for defects or inconsistencies.

2. Quality Control

Toilet Products Molders are responsible for maintaining the quality of the products they produce.

- Conduct regular quality checks on molded products.

- Identify and correct defects in molded products.

- Follow established quality standards and procedures.

3. Production Management

Toilet Products Molders are involved in managing the production process to ensure efficiency and meet production goals.

- Monitor production lines to identify and resolve bottlenecks.

- Make adjustments to molding parameters to improve product quality and efficiency.

- Maintain a clean and organized work area.

4. Maintenance and Troubleshooting

Toilet Products Molders are responsible for performing basic maintenance and troubleshooting on molding equipment.

- Perform routine maintenance on molding machines.

- Troubleshoot and resolve machine malfunctions.

- Communicate maintenance and repair needs to supervisors.

Interview Tips

Preparing for an interview for a Toilet Products Molder position requires a combination of technical knowledge and an understanding of the industry. Here are some tips to help you ace your interview:

1. Research the Company and Position

Thoroughly research the company you’re applying to and the specific role of a Toilet Products Molder within their organization. This will give you a better understanding of their production processes, quality standards, and the company culture.

- Visit the company’s website and social media pages.

- Read industry news and articles to gain insights into the latest trends.

2. Highlight Your Technical Skills

Emphasize your technical skills related to molding and shaping processes. Provide specific examples of your experience operating molding machinery and maintaining equipment. Quantify your accomplishments whenever possible.

- Discuss your knowledge of different types of molding machines and their applications.

- Provide examples of how you have improved production efficiency or reduced defects.

3. Demonstrate Your Quality Consciousness

Highlight your commitment to quality and your ability to identify and correct defects. Share examples of your quality control measures and how you have ensured that products meet specifications.

- Explain your understanding of industry quality standards and regulations.

- Discuss how you have implemented quality control measures to improve product quality.

4. Emphasize Your Work Ethic and Team Skills

Toilet Products Molders work in a fast-paced production environment and need to be reliable and able to work effectively as part of a team. Showcase your strong work ethic, attention to detail, and ability to collaborate with others.

- Provide examples of how you have managed production schedules and met deadlines.

- Discuss your experience working in a team environment and how you have contributed to its success.

Next Step:

Now that you’re armed with the knowledge of Toilet Products Molder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Toilet Products Molder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini