Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool and Cutter Grinder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool and Cutter Grinder so you can tailor your answers to impress potential employers.

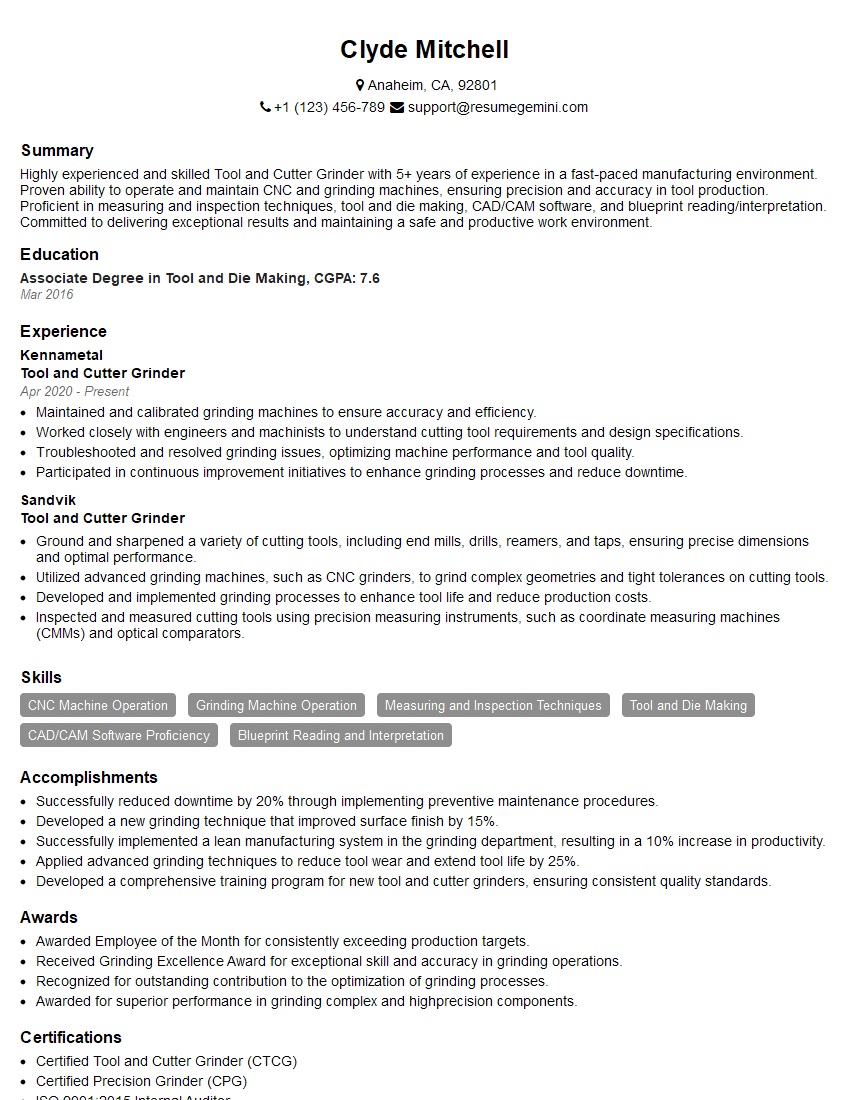

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Cutter Grinder

1. What are the different types of grinding machines used in tool and cutter grinding?

There are various types of grinding machines used in tool and cutter grinding, including:

- Surface grinders: Used for grinding flat surfaces on tools and cutters.

- Cylindrical grinders: Used for grinding cylindrical surfaces on tools and cutters.

- Internal grinders: Used for grinding internal surfaces on tools and cutters.

- Centerless grinders: Used for grinding round workpieces without the need for centers.

- Jig grinders: Used for grinding complex shapes and profiles on tools and cutters.

2. How do you calculate the grinding wheel speed and feed rate for a given grinding operation?

Factors to Consider for Grinding Wheel Speed:

- Type of abrasive material

- Workpiece material

- Diameter of the grinding wheel

- Desired surface finish

Factors to Consider for Feed Rate:

- Material removal rate

- Surface finish requirements

- Machine capabilities

3. What are the different types of coolants used in tool and cutter grinding?

The most common types of coolants used in tool and cutter grinding are:

- Water-soluble oils: Provide good cooling, lubrication, and rust protection.

- Synthetic coolants: Offer longer tool life and improved surface finish compared to water-soluble oils.

- Cryogenic coolants: Provide extreme cooling, resulting in reduced thermal damage and improved tool life.

4. How do you measure and control the accuracy of a grinding operation?

Accuracy in tool and cutter grinding can be measured and controlled through various methods, including:

- Gage blocks: Used to calibrate and set grinding machines.

- Dial indicators: Used to measure small dimensional changes and alignments.

- Coordinate measuring machines (CMMs): Used to measure complex shapes and profiles with high precision.

- Laser interferometers: Used for highly accurate measurements of linear displacement and angular motion.

5. What are the safety precautions that must be followed when operating a tool and cutter grinder?

- Wear proper safety gear, including eye protection, gloves, and appropriate clothing.

- Ensure the machine is properly grounded and all guards are in place.

- Inspect the grinding wheel for cracks or damage before use.

- Maintain a safe working environment free from tripping hazards and debris.

- Follow the manufacturer’s instructions for proper machine operation and maintenance.

6. How do you troubleshoot common problems encountered in tool and cutter grinding?

- Excessive wheel wear: Check for dull or glazed wheels, improper wheel selection, or excessive grinding pressure.

- Poor surface finish: Adjust grinding parameters such as wheel speed, feed rate, or coolant flow.

- Chatter or vibration: Ensure the workpiece and machine are properly secured, check for unbalanced wheels or worn bearings.

- Burning of the workpiece: Reduce grinding pressure, adjust coolant flow, or select a more suitable grinding wheel.

- Wheel breakage: Inspect the wheel for cracks or damage, ensure proper mounting and balance.

7. What are the different types of abrasive materials used in tool and cutter grinding?

The primary types of abrasive materials used in tool and cutter grinding include:

- Aluminum oxide: General-purpose abrasive, suitable for various materials and applications.

- Silicon carbide: Harder and more durable than aluminum oxide, ideal for grinding hard materials like tungsten carbide.

- Cubic boron nitride (CBN): Extremely hard and wear-resistant, used for grinding high-alloy steels and ceramics.

- Diamond: The hardest abrasive, used for grinding extremely hard materials like diamond and glass.

8. How do you select the appropriate grinding wheel for a specific grinding operation?

The selection of a suitable grinding wheel depends on several factors, including:

- Material of the workpiece

- Desired surface finish

- Type of grinding operation (e.g., surface, cylindrical, internal)

- Size and shape of the grinding wheel

- Wheel grit size and bond type

9. What are the key factors that influence the quality of a ground surface?

- Sharpness and condition of the grinding wheel

- Proper selection and application of coolant

- Appropriate grinding parameters (e.g., speed, feed, depth of cut)

- Accuracy and stability of the grinding machine

- Skill and experience of the operator

10. What are the emerging trends and technologies in tool and cutter grinding?

The tool and cutter grinding industry is constantly evolving, with advancements in areas such as:

- Automated grinding systems with CNC controls

- High-precision and ultra-fine grinding techniques

- Use of advanced abrasive materials and coatings

- Implementation of artificial intelligence (AI) and machine learning for process optimization

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Cutter Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Cutter Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Cutter Grinders are responsible for the day-to-day sharpening and maintenance of cutting tools used in various industries, such as manufacturing, construction, and woodworking. They ensure that tools are in optimal condition to perform their intended functions efficiently and safely.

1. Sharpening and Regrinding

Grind and sharpen cutting tools, such as milling cutters, drills, saws, and reamers, using specialized grinding machines.

- Operate grinding machines to remove material from tools, restoring their sharp edges and contours.

- Select appropriate abrasives and grinding wheels based on the type of tool and material.

2. Inspection and Measurement

Inspect and measure cutting tools using various tools and gauges to ensure accuracy and conformance to specifications.

- Calibrate and maintain measuring equipment to ensure precise measurements.

- Check tool dimensions, angles, and surface finish against blueprints or specifications.

3. Maintenance and Repair

Perform basic maintenance and repairs on grinding machines and other equipment used in the grinding process.

- Lubricate and clean machines regularly to prevent breakdowns and ensure smooth operation.

- Diagnose and troubleshoot any malfunctions or issues with grinding equipment.

4. Quality Control

Monitor the quality of sharpened tools and ensure they meet industry standards.

- Test tools using appropriate methods to verify their sharpness and accuracy.

- Document and maintain records of grinding parameters and quality control checks.

Interview Tips

Preparing for an interview for a Tool and Cutter Grinder position requires a combination of technical knowledge, industry experience, and effective communication skills.

1. Research the Company and Industry

Familiarize yourself with the company’s background, products or services, and industry trends. This will help you understand their specific needs and how your skills can align with their goals.

- Visit the company website, read industry articles, and attend relevant events to gather information.

- Study the job description thoroughly to identify the key responsibilities and qualifications required for the role.

2. Highlight Your Skills and Experience

Emphasize your technical proficiency in sharpening and regrinding cutting tools, including your knowledge of grinding machines and abrasives. Quantify your experience with specific examples and metrics.

- Prepare examples of complex grinding projects you have completed successfully.

- Showcase your ability to inspect and measure tools precisely using various gauges and measuring equipment.

3. Demonstrate Problem-Solving Abilities

Tool and Cutter Grinders often encounter challenges in their work. Discuss situations where you have diagnosed and resolved issues with grinding machines or sharpened tools.

- Provide specific examples of how you troubleshoot and repair grinding equipment.

- Highlight your ability to think critically and find innovative solutions to problems.

4. Emphasize Safety and Quality Control

Safety and quality are paramount in the role of a Tool and Cutter Grinder. Communicate your commitment to following safety protocols and maintaining high standards of workmanship.

- Explain how you ensure the accuracy and precision of your work through regular inspections and quality control checks.

- Share your understanding of industry regulations and standards related to tool sharpening and grinding.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool and Cutter Grinder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.