Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool and Die Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool and Die Assembler so you can tailor your answers to impress potential employers.

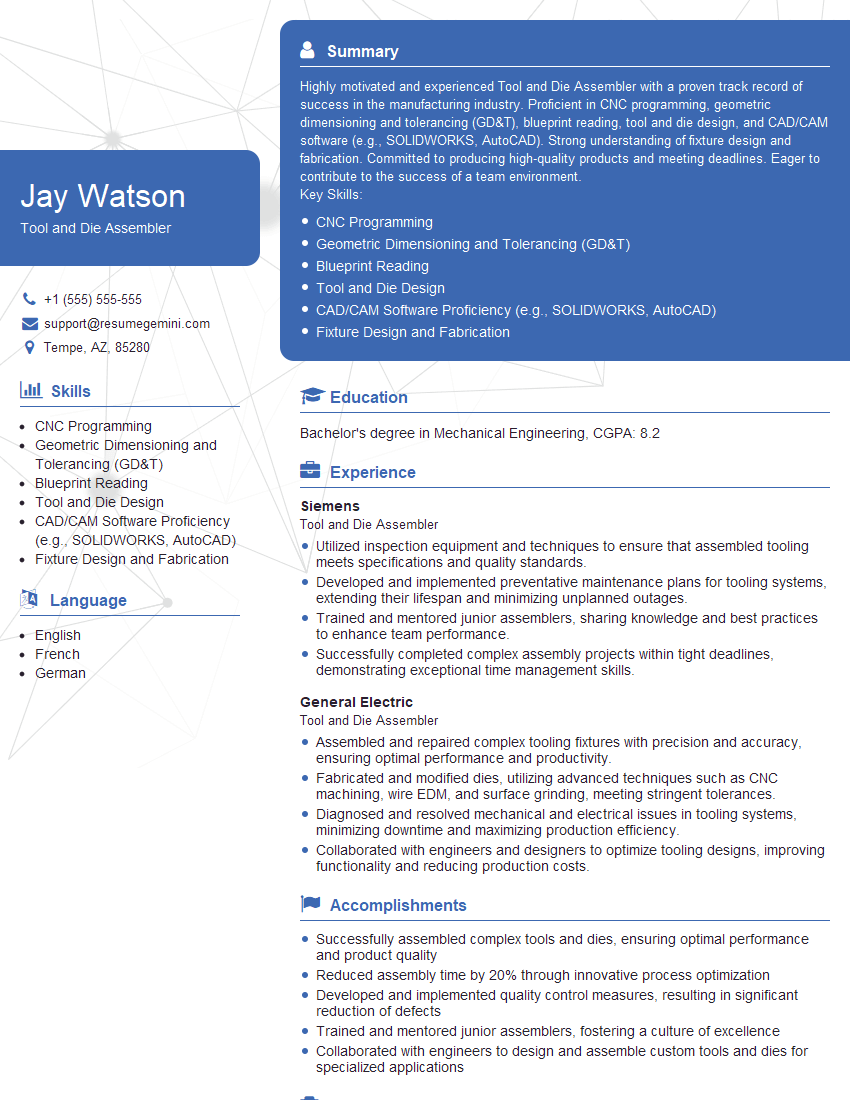

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Assembler

1. Explain the steps involved in assembling a tool and die.

The steps involved in assembling a tool and die are as follows:

- Inspect the parts to ensure they are free of defects.

- Clean and deburr the parts as necessary.

- Apply a lubricant to the mating surfaces of the parts.

- Assemble the parts in the correct order.

- Tighten the fasteners to the specified torque.

- Inspect the assembled tool and die to ensure it meets the required specifications.

2. What are the different types of materials used in tool and die making?

Metals

- Steel

- Aluminum

- Copper

- Brass

Plastics

- Polyethylene

- Polypropylene

- Polyvinyl chloride

- ABS

3. What are the different types of machines used in tool and die making?

- Milling machines

- Lathes

- Grinders

- EDM machines

- Wire EDM machines

4. What are the different types of tools used in tool and die making?

- Cutting tools

- Forming tools

- Gauges

- Fixtures

- Measuring instruments

5. What are the different types of processes used in tool and die making?

- Milling

- Turning

- Grinding

- EDM

- Wire EDM

- Heat treating

- Coating

6. What are the different types of quality control checks performed in tool and die making?

- Dimensional inspection

- Surface finish inspection

- Hardness testing

- Fatigue testing

- Functional testing

7. What are the different types of safety precautions that should be taken when working in a tool and die shop?

- Wear appropriate safety gear, including eye protection, hearing protection, and gloves.

- Be aware of the hazards associated with the machines and tools being used.

- Keep the work area clean and free of debris.

- Follow all safety procedures and regulations.

8. What are the different types of career opportunities available in tool and die making?

- Tool and die maker

- Tool and die designer

- Tool and die engineer

- Tool and die manager

- Tool and die instructor

9. What is the difference between a tool and a die?

A tool is a device used to shape or form another object. A die is a tool that is used to cut or form a material to a specific shape.

10. What is the difference between a mold and a die?

A mold is a tool that is used to create a part by forming a liquid material into a specific shape. A die is a tool that is used to cut or form a material to a specific shape.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Assemblers play a pivotal role in the production of complex metal components and assemblies. Their key responsibilities encompass:

1. Assembly

Assemble and fit precision tools, dies, and fixtures according to engineering specifications.

- Interpret blueprints and technical drawings to understand assembly requirements.

- Use hand tools, power tools, and specialized equipment to assemble and adjust components with accuracy.

2. Inspection

Inspect assembled components and assemblies to ensure compliance with quality standards.

- Conduct dimensional measurements using gauges, calipers, and measuring instruments.

- Verify that components meet specifications for fit, finish, and functionality.

3. Maintenance

Maintain and troubleshoot tools, dies, and fixtures to ensure optimal performance.

- Clean and lubricate components to prevent wear and tear.

- Identify and resolve mechanical issues to minimize downtime and maintain productivity.

4. Collaboration

Collaborate with engineers, designers, and other team members to improve assembly processes.

- Provide input on design modifications and assembly techniques.

- Participate in problem-solving sessions to find solutions to manufacturing challenges.

Interview Tips

Preparing for a Tool and Die Assembler interview requires a combination of technical knowledge, industry experience, and interview skills. Here are some valuable tips to help you ace the interview:

1. Research the company and the role

Thoroughly research the company’s business, its products or services, and the specific requirements of the Tool and Die Assembler role. This will help you understand the company culture, the job expectations, and how your skills and experience align with the position.

- Visit the company website and read about their history, mission, and products.

- Check out the company’s social media presence to get a sense of their culture and values.

- Review the job description carefully and identify the key skills and responsibilities.

2. Practice your answers to common interview questions

Prepare for common interview questions related to your technical skills, experience, and problem-solving abilities. Practice answering these questions clearly and concisely, highlighting your relevant qualifications and accomplishments.

- Describe your experience in assembling and inspecting tools and dies.

- Give an example of a time when you resolved a complex assembly issue.

- How do you stay up-to-date with industry best practices and technological advancements?

3. Be prepared to discuss your knowledge of tools and equipment

Tool and Die Assemblers use a variety of tools and equipment, such as lathes, mills, grinders, and measuring instruments. Be prepared to discuss your proficiency with these tools and how you use them in your work.

- Describe your experience with manual and CNC machine tools.

- Explain how you use measuring instruments, such as calipers and micrometers, to ensure accuracy.

- Discuss your knowledge of quality control processes and inspection techniques.

4. Emphasize your attention to detail and accuracy

Tool and Die Assemblers must be highly detail-oriented and accurate in their work. Highlight your ability to follow precise instructions, meet tight tolerances, and produce high-quality assemblies.

- Provide examples of how you have maintained accuracy in your previous roles.

- Explain how you use quality control processes to ensure precision and consistency.

- Describe your understanding of the importance of adhering to safety protocols in the workplace.

5. Be ready to talk about your teamwork and communication skills

Tool and Die Assemblers often work as part of a team and must be able to communicate effectively with engineers, designers, and other team members. Be prepared to discuss your teamwork and communication skills, and provide examples of how you have collaborated successfully in a team environment.

- Describe your experience working on team projects and how you contributed to the team’s success.

- Explain how you communicate effectively with people from different backgrounds and technical expertise.

- Give an example of a time when you successfully resolved a conflict or issue with a team member.

Next Step:

Now that you’re armed with the knowledge of Tool and Die Assembler interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tool and Die Assembler positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini