Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool and Die Machinist interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool and Die Machinist so you can tailor your answers to impress potential employers.

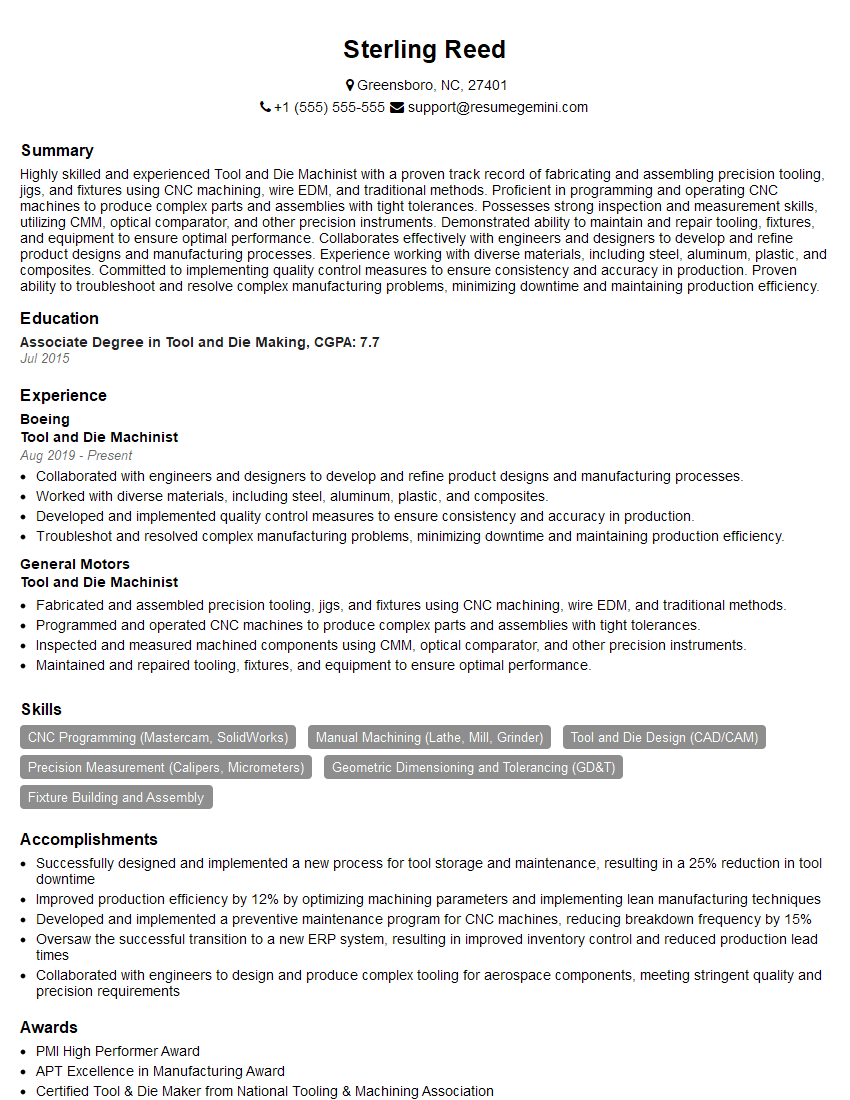

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Machinist

1. How do you ensure the accuracy of your measurements when working with tight tolerances?

I follow a systematic approach to ensure accuracy:

- Calibrated measuring equipment regularly

- Double-check measurements using multiple tools

- Use precision instruments for critical dimensions

- Allow for material expansion and contraction

2. What is your process for designing and creating complex tooling?

Analysis and Planning

- Understand design specifications and tolerance requirements

- Choose appropriate materials and manufacturing methods

- Develop detailed design drawings and CAM programs

Fabrication and Assembly

- Machine and fabricate individual components

- Heat treat and finish components as needed

- Assemble and test tooling to ensure proper functionality

3. Describe your experience with different types of materials used in tooling.

I have worked with a wide range of materials, including:

- Tool steels (HSS, carbide, CPM)

- Engineering plastics and composites

- Aluminum and other non-ferrous metals

- Ceramics and diamond-like coatings

4. How do you interpret complex engineering drawings and translate them into production plans?

I use my knowledge of engineering principles and industry standards to:

- Analyze drawings and identify key dimensions and tolerances

- Determine the sequence of operations and tooling required

- Create detailed work instructions and production schedules

5. Describe your experience with CNC programming and simulation software.

I am proficient in using the following software:

- Mastercam

- SolidWorks CAM

- GibbsCAM

I use these tools to generate complex toolpaths, simulate machining operations, and optimize production efficiency.

6. How do you maintain and troubleshoot production equipment?

I perform regular maintenance tasks, such as:

- Cleaning and lubricating machinery

- Replacing worn parts and consumables

- Inspecting and adjusting equipment settings

For troubleshooting, I follow a logical process to:

- Identify potential causes of problems

- Test and verify theories

- Implement solutions and monitor results

7. What quality assurance techniques do you use to ensure the integrity of your work?

I employ the following quality assurance practices:

- Adhering to ISO and industry quality standards

- Performing regular inspections and testing

- Maintaining detailed production records

- Collaborating with quality control teams

8. Describe your experience with working in a team environment.

I am a collaborative and effective team player:

- Communicate effectively with colleagues and supervisors

- Share knowledge and experience to support team goals

- Take on leadership roles when required

- Adapt to different work styles and personalities

9. How do you stay up-to-date on industry trends and advancements?

I actively seek opportunities to learn and grow:

- Attend industry conferences and workshops

- Read technical publications and articles

- Participate in professional organizations

- Explore new technologies and applications

10. What are your career aspirations and how do you see this role contributing to them?

I am passionate about tool and die making, and I aspire to become a lead machinist or a master toolmaker.

This role would provide me with an excellent opportunity to:

- Expand my technical skills and knowledge

- Work on challenging projects and contribute to innovative solutions

- Build relationships with industry professionals

- Advance my career and make a significant impact in the field

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Machinists play a crucial role in the manufacturing industry by creating and maintaining tools, dies, and fixtures used in the production process. Their core responsibilities include:

1. Tool and Die Design and Fabrication

Interpreting engineering drawings and specifications to design, fabricate, and modify tools and dies.

- Selecting appropriate materials and processes for tool and die construction.

- Operating precision machinery such as CNC mills, lathes, and grinders to shape and finish tools and dies.

2. Quality Control and Inspection

Ensuring the accuracy and precision of tools and dies by performing rigorous inspections and measurements.

- Using precision measuring instruments and gauges to verify dimensions and tolerances.

- Identifying and correcting any deviations from design specifications.

3. Machine and Equipment Maintenance

Maintaining and repairing machinery and equipment used in the tool and die shop.

- Troubleshooting and diagnosing equipment malfunctions.

- Performing routine maintenance and repairs to ensure optimal performance.

4. Collaboration with Design and Engineering Teams

Working closely with design and engineering teams to provide input on tool and die design.

- Reviewing engineering drawings and providing feedback on manufacturability.

- Suggesting improvements to tool and die designs based on experience and expertise.

Interview Tips

Preparing thoroughly for a Tool and Die Machinist interview can significantly enhance your chances of success. Consider the following tips:

1. Research the Company and Role

Gain a thorough understanding of the company’s products, services, and industry. Research the specific role you are applying for and identify the key responsibilities.

2. Highlight Your Technical Skills

Showcase your expertise in tool and die design, fabrication, and maintenance. Provide specific examples of complex projects you have completed and the techniques you employed.

3. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to solve problems and make quick decisions. Share examples of how you have identified and resolved tool or die issues.

4. Emphasize Your Attention to Detail

Precision and accuracy are paramount in this role. Highlight your meticulous approach to quality control and inspection.

5. Prepare Questions for the Interviewers

Asking thoughtful questions about the company, the role, and the industry demonstrates your engagement and interest. It also provides an opportunity to clarify any uncertainties.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool and Die Machinist interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.