Are you gearing up for a career in Tool and Die Maker/Designer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tool and Die Maker/Designer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

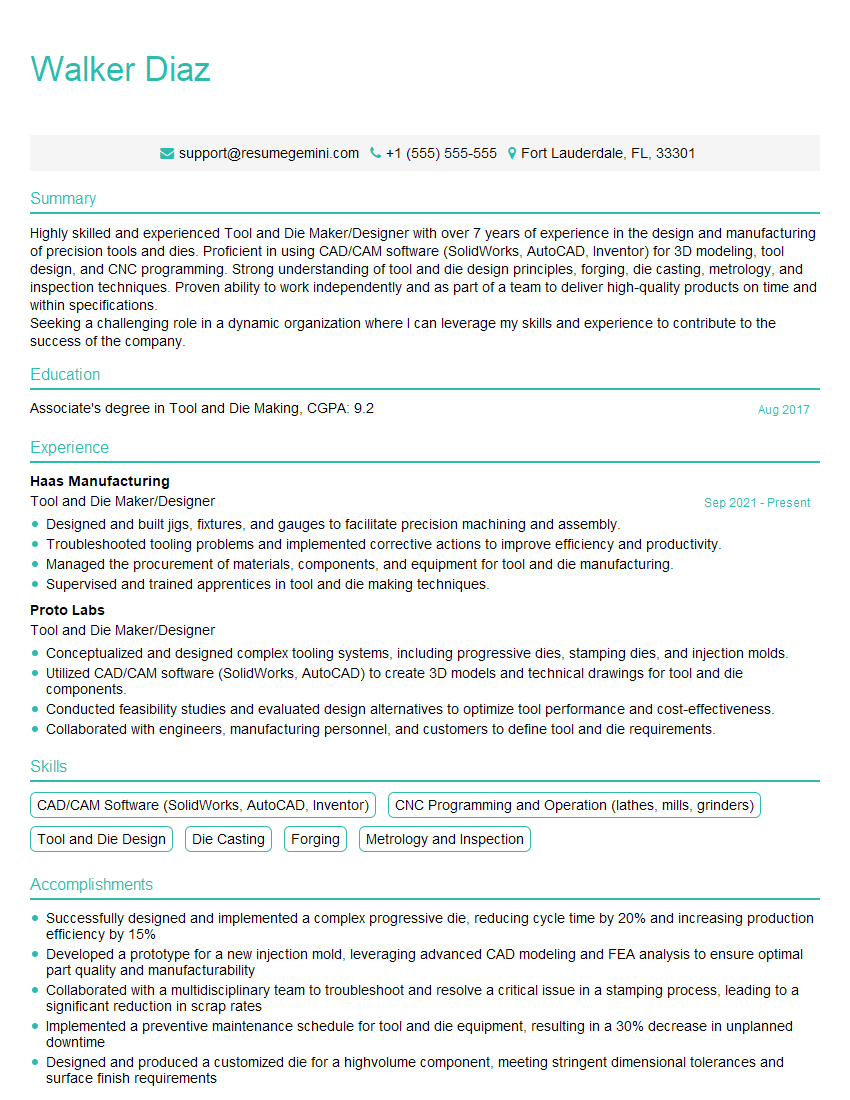

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Maker/Designer

1. What is the difference between a jig and a fixture?

A jig is a device that holds and guides a tool or workpiece during a machining operation, while a fixture is a device that holds a workpiece securely in place during a machining operation. Jigs are typically used for drilling, reaming, and tapping operations, while fixtures are typically used for milling, turning, and grinding operations.

2. What are the different types of presses used in tool and die making?

Mechanical presses

- C-frame presses

- Straight-side presses

- Gap presses

Hydraulic presses

- Upacting presses

- Downacting presses

- Side-acting presses

3. What are the different types of dies used in tool and die making?

- Blanking dies

- Piercing dies

- Forming dies

- Compound dies

- Progressive dies

4. What are the different types of materials used in tool and die making?

- Tool steels

- Alloy steels

- Stainless steels

- Carbide

- Ceramics

5. What are the different types of finishes used on tools and dies?

- Polishing

- Grinding

- Honing

- Lapping

- Superfinishing

6. What are the different types of tolerances used in tool and die making?

- Linear tolerances

- Angular tolerances

- Geometric tolerances

- Surface finish tolerances

7. What are the different types of testing methods used in tool and die making?

- Dimensional testing

- Functional testing

- Fatigue testing

- Corrosion testing

- Wear testing

8. What are the different types of software used in tool and die making?

- CAD software

- CAM software

- CAE software

- ERP software

- PDM software

9. What are the different types of safety precautions that must be taken in tool and die making?

- Wear appropriate PPE

- Use guards and shields on machinery

- Be aware of pinch points

- Store tools and materials properly

- Follow all safety procedures

10. What are the different types of career opportunities available in tool and die making?

- Tool and die maker

- Tool and die designer

- Tool and die engineer

- Tool and die manager

- Tool and die instructor

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Maker/Designer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Maker/Designer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Makers/Designers are responsible for the design, construction, and maintenance of tools, dies, and fixtures used in manufacturing processes. They work closely with engineers to develop and implement new product designs, and they also provide technical support to production staff.

1. Design and Drafting

Tool and Die Makers/Designers use their knowledge of engineering principles and materials to design and draft tools, dies, and fixtures. They use computer-aided design (CAD) software to create detailed drawings that specify the dimensions and tolerances of the parts they are creating.

2. Fabrication and Assembly

Once the design is complete, Tool and Die Makers/Designers fabricate and assemble the tools, dies, and fixtures. They use a variety of machining tools and techniques to create the parts, and they also use welding and assembly techniques to put them together.

3. Maintenance and Repair

Tool and Die Makers/Designers also perform maintenance and repair work on tools, dies, and fixtures. They inspect the parts for wear and damage, and they make repairs as needed. They also calibrate the parts to ensure that they are operating correctly.

4. Product Development

In addition to their other responsibilities, Tool and Die Makers/Designers may also be involved in product development. They may work with engineers to develop new product designs, and they may also help to create prototypes of new products.

Interview Tips

To ace the interview for a Tool and Die Maker/Designer position, candidates should prepare by:

1. Researching the Company and the Position

Candidates should research the company they are applying to, as well as the specific position they are interviewing for. This will help them to understand the company’s culture and values, as well as the specific requirements of the job.

2. Preparing Questions for the Interviewer

Candidates should prepare a list of questions to ask the interviewer. This will show that they are interested in the position and that they have done their research. It is also a good way to get more information about the company and the position.

3. Practicing Their Answers to Common Interview Questions

Candidates should practice their answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” This will help them to feel more confident and prepared during the interview.

4. Dressing Professionally and Arriving on Time

Candidates should dress professionally and arrive on time for their interview. This will show that they are respectful of the interviewer’s time and that they are serious about the position.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool and Die Maker/Designer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.