Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool and Die Maker Level Five position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

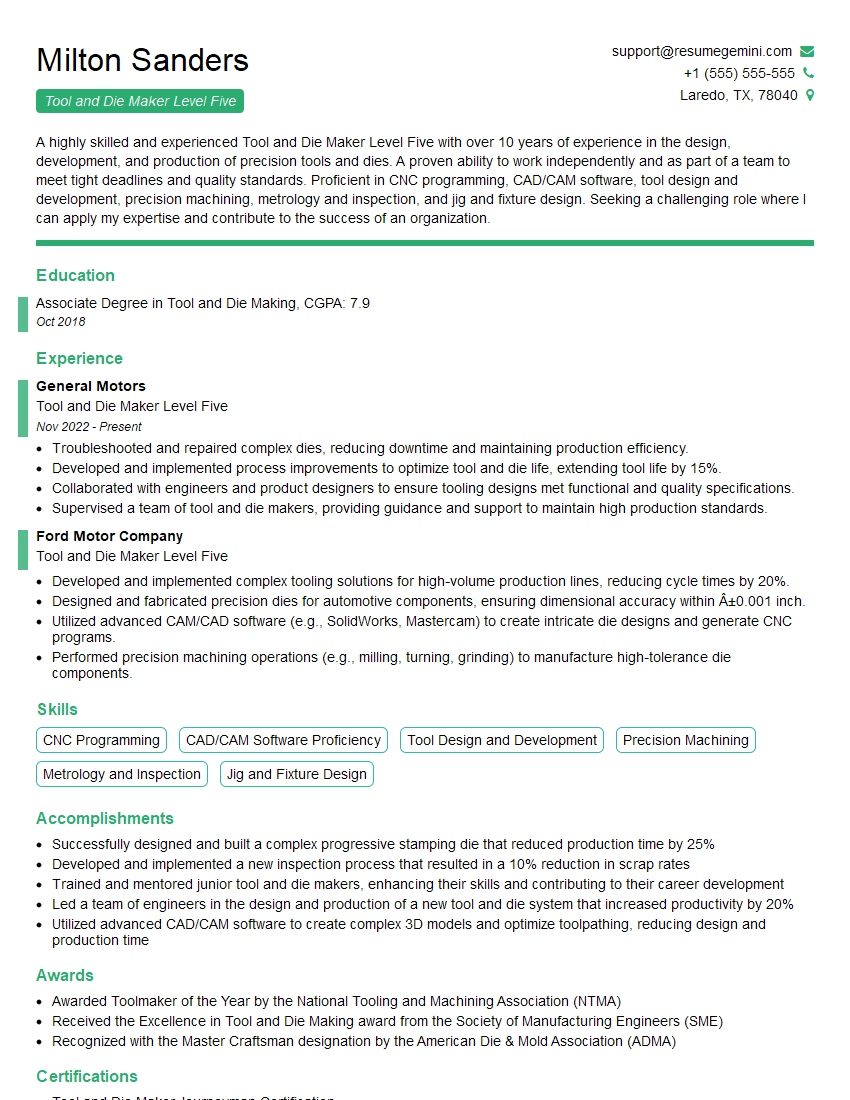

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Maker Level Five

1. Describe the process of designing a progressive die and the factors to consider.

In designing a progressive die, I follow a comprehensive approach that ensures efficiency and precision. Key factors I consider include:

- Component Geometry: Analyzing the part’s shape, size, and material properties to determine the required tooling operations.

- Material Selection: Choosing appropriate tool steels based on the material being formed, desired tolerances, and durability requirements.

- Stripping Mechanisms: Determining the best stripper design to prevent material wrinkling and ensure proper part ejection during each station.

- Clearance and Cutting Angles: Calculating optimal clearance and cutting angles to minimize material distortion and maximize tool life.

- Station Layout: Planning the sequence of operations and distributing them across multiple stations to achieve maximum productivity and minimize scrap.

2. How do you determine the appropriate heat treatment for a tool and die?

Determining the appropriate heat treatment involves several considerations:

Material Properties:

- Assessing the tool steel’s chemical composition and hardness requirements.

Tool Function:

- Understanding the specific purpose of the tool, such as cutting, forming, or stamping.

Heat Treatment Process:

- Selecting the appropriate heat treatment method (e.g., quenching, tempering, annealing) based on the desired properties.

- Controlling temperature, heating rates, and cooling rates to achieve optimal microstructure and mechanical performance.

3. Explain the different types of press brake forming and their applications.

Press brake forming involves bending sheet metal using a variety of techniques:

- Air Bending: Using a punch and die set to bend the material over a sharp edge, creating an angle.

- Bottom Bending: Holding the material down with a pressure pad while the punch forms the bend, resulting in a more precise angle.

- Coining: Using a punch and die set to press the material into a specific shape, producing intricate bends and complex profiles.

- Hemming: Folding the material over itself to create a reinforced edge, improving structural integrity and aesthetics.

4. Describe the principles of wire electrical discharge machining (EDM) and its advantages in tool and die making.

Wire EDM is a precise machining process that utilizes a thin wire electrode to cut conductive materials by eroding them with electrical sparks. Its advantages in tool and die making include:

- Complex Geometries: Wire EDM allows for the creation of intricate and complex shapes that are difficult to achieve with traditional machining methods.

- Material Versatility: It can machine a wide range of conductive materials, including hardened steel, carbide, and titanium.

- Precision and Accuracy: Wire EDM provides extremely precise cuts with high accuracy and repeatability.

- No Tool Wear: The wire electrode does not wear during the process, eliminating the need for tool changes and ensuring consistent cutting performance.

5. How do you troubleshoot and resolve common problems with CNC machines?

Troubleshooting and resolving CNC machine problems requires a systematic approach:

- Diagnostics: Using diagnostic tools and software to identify error codes, determine the source of the problem, and evaluate the machine’s condition.

- Mechanical Inspection: Checking for loose connections, misaligned components, or mechanical damage that could affect machine operation.

- Software Analysis: Reviewing program codes and parameters to identify any errors or inconsistencies that may cause malfunctions.

- Test Runs: Performing controlled test runs with modified parameters or adjusted components to determine the root cause of the problem.

- Repairs and Adjustments: Implementing appropriate repair or adjustment procedures to restore the machine to optimal operating condition.

6. Explain the principles of injection molding and its applications in the manufacturing of plastic parts.

Injection molding is a widely used manufacturing process for producing plastic parts. It involves the following steps:

- Mold Design: Designing and creating molds that define the shape of the part being molded.

- Material Selection: Choosing the appropriate plastic material based on the desired properties and application requirements.

- Injection: Melting the plastic material and injecting it into the mold under high pressure.

- Cooling and Solidification: Maintaining the material under pressure and temperature until it solidifies and takes the shape of the mold.

- Ejection: Opening the mold and ejecting the molded part.

7. Describe the different types of welding processes used in tool and die making and their respective advantages.

Various welding processes are employed in tool and die making, each offering unique advantages:

- TIG Welding: Using a non-consumable tungsten electrode and a shielding gas to create precise and high-quality welds.

- MIG Welding: Using a continuously fed consumable wire electrode and shielding gas for fast and efficient welding.

- Arc Welding: Using a consumable stick electrode and shielding gas to produce strong and durable welds.

- Laser Welding: Utilizing a focused laser beam to create deep and narrow welds with minimal heat distortion.

8. Explain the quality control measures implemented in tool and die making to ensure precision and accuracy.

Ensuring precision and accuracy in tool and die making involves rigorous quality control measures:

- Dimensional Inspection: Using precision measuring instruments (e.g., CMM, dial indicators) to verify dimensions and tolerances meet specifications.

- Surface Finish Analysis: Evaluating the surface finish of tools and dies to ensure they meet the required smoothness and roughness parameters.

- Hardness Testing: Measuring the hardness of tools and dies to ensure they have the appropriate strength and durability.

- Functional Testing: Conducting trials to assess the performance of tools and dies in real-world applications.

- Documentation and Traceability: Maintaining comprehensive records of all quality control procedures and results for traceability and accountability.

9. Describe your experience in using CAD/CAM software for tool and die design and manufacturing.

I am proficient in using industry-standard CAD/CAM software, including:

- Computer-Aided Design (CAD): SolidWorks, AutoCAD

- Computer-Aided Manufacturing (CAM): Mastercam, CAMWorks

I utilize these software tools throughout the design and manufacturing process:

- 3D Modeling: Creating precise 3D models of tools and dies.

- Toolpath Generation: Generating optimal toolpaths for CNC machines.

- Simulation and Verification: Simulating the manufacturing process to identify potential issues and ensure accuracy.

10. How do you stay updated with the latest advancements and technologies in the field of tool and die making?

- Industry Publications: Subscribing to industry magazines and journals to stay informed about new technologies and best practices.

- Conferences and Trade Shows: Attending industry events to learn about the latest advancements and connect with professionals.

- Online Resources: Utilizing online forums, technical discussions, and webinars to access up-to-date information.

- Continuing Education: Pursuing additional certifications and training programs to enhance my skills and knowledge.

- Networking: Engaging with other professionals in the field to exchange ideas and stay abreast of industry trends.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Maker Level Five.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Maker Level Five‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Maker Level Five is a highly skilled position that requires a deep understanding of tool and die making principles. The key job responsibilities include:

1. Designing and building tools, dies, and fixtures

Tool and Die Makers design and build tools, dies, and fixtures that are used to manufacture a variety of products. These tools and dies must be precise and durable, and they must meet the specific requirements of the product being manufactured.

- Analyze product designs and specifications to determine the necessary tools, dies, and fixtures.

- Design and create detailed drawings of the tools, dies, and fixtures.

- Select the appropriate materials and manufacturing processes for the tools, dies, and fixtures.

- Fabricate and assemble the tools, dies, and fixtures using precision machining and other techniques.

2. Maintaining and repairing tools, dies, and fixtures

Tool and Die Makers maintain and repair tools, dies, and fixtures to ensure that they are in good working condition. They also perform preventive maintenance to extend the life of the tools, dies, and fixtures.

- Inspect tools, dies, and fixtures for wear and tear.

- Repair or replace damaged or worn components.

- Perform preventive maintenance on tools, dies, and fixtures to prevent problems.

3. Operating and troubleshooting CNC machines

Tool and Die Makers often operate CNC machines to create tools, dies, and fixtures. They also troubleshoot problems with CNC machines and ensure that they are operating properly.

- Operate CNC machines to create tools, dies, and fixtures.

- Program CNC machines to create complex parts.

- Troubleshoot problems with CNC machines and repair them.

4. Working with other departments

Tool and Die Makers often work with other departments in the manufacturing process. They may work with engineers to design new products or with production workers to set up and operate production lines.

- Work with engineers to design new products.

- Collaborate with production workers to set up and operate production lines.

- Train other employees on the use of tools, dies, and fixtures.

Interview Tips

To ace the interview for a Tool and Die Maker Level Five position, it is important to prepare thoroughly. Here are a few tips:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and the requirements of the position. You can find information about the company on its website, LinkedIn, or other online sources.

- Visit the company’s website to learn about its history, products, and services.

- Read the job description carefully and make note of the key requirements.

- Research the industry to understand the current trends and challenges.

2. Practice your answers to common interview questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief summary of your experience and skills.

- Highlight your key accomplishments and how they relate to the position you are applying for.

- Be prepared to answer questions about your strengths and weaknesses.

3. Be prepared to talk about your experience with tools, dies, and fixtures

The interviewer will want to know about your experience with tools, dies, and fixtures. Be prepared to discuss your skills in designing, building, maintaining, and repairing tools, dies, and fixtures. You may also be asked about your experience with CNC machines.

- Describe your experience with different types of tools, dies, and fixtures.

- Provide examples of projects that you have worked on.

- Discuss your experience with CNC machines and programming.

4. Be professional and enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be respectful of the interviewer’s time. Be confident in your abilities and be prepared to answer questions about your experience and skills.

- Dress professionally and arrive on time for your interview.

- Be respectful of the interviewer’s time and answer questions honestly and concisely.

- Be enthusiastic about the position and the company.

Next Step:

Now that you’re armed with the knowledge of Tool and Die Maker Level Five interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Tool and Die Maker Level Five positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini