Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Tool and Die Repair interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Tool and Die Repair so you can tailor your answers to impress potential employers.

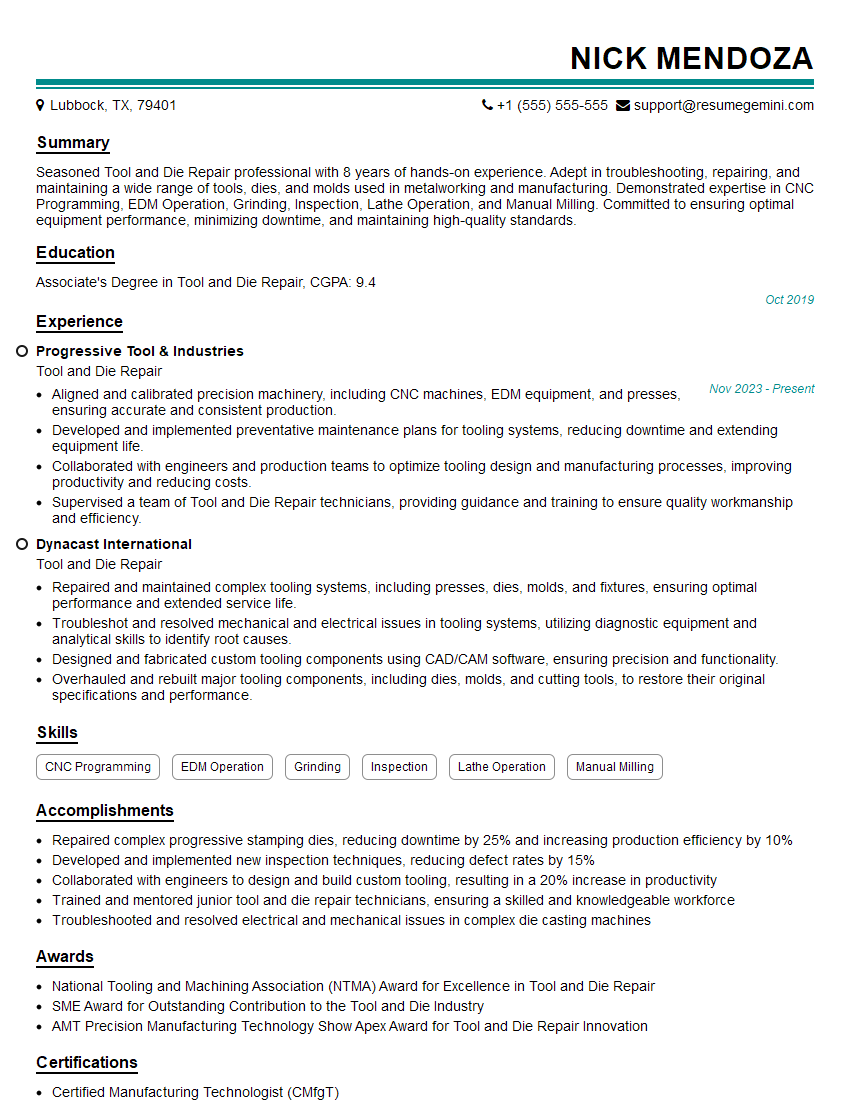

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Repair

1. Describe the key differences between blanking and piercing operations?

- Blanking: Creates an external shape by cutting the material completely through.

- Piercing: Creates an internal shape by cutting a hole completely through the material.

2. What is the purpose of using a clearance angle on a die?

To prevent the material from sticking to the die during the stamping process

- Provides a space between the die and the material.

- Allows the material to flow away from the die as it is cut.

To improve the quality of the cut edge

- Reduces burring and distortion.

- Produces a smoother and cleaner edge.

3. How do you determine the proper clearance between the punch and die?

- The material thickness and type.

- The desired fit between the punch and die.

- The type of press and stamping operation being used.

4. Describe the different types of grinders used in tool and die making?

- Surface Grinder: Used for grinding flat surfaces.

- Cylindrical Grinder: Used for grinding cylindrical surfaces.

- Centerless Grinder: Used for grinding round workpieces without the need for centers.

- Tool and Cutter Grinder: Used for grinding cutting tools and dies.

- Electrochemical Grinder (ECG): Used for grinding complex shapes and difficult-to-machine materials.

5. What are the steps involved in making a simple stamping die?

- Design the die: Create the 2D and 3D design of the die using CAD software.

- Select the materials: Choose the appropriate materials for the die components based on the required durability and accuracy.

- Manufacture the die components: Use CNC machines, grinders, and other tools to manufacture the die components with precision.

- Assemble the die: Put together the die components and align them precisely.

- Try out the die: Test the die on a press to check its functionality and make any necessary adjustments.

6. What are the common quality control checks performed on tool and die components?

- Dimensional accuracy: Using micrometers, calipers, and other measuring tools.

- Surface roughness: Using surface roughness testers.

- Hardness: Using Rockwell or Vickers hardness testers.

- Heat treatment verification: Using hardness testing or metallographic examination.

- Functional testing: Testing the die components in a press to ensure they perform as intended.

7. How do you maintain and troubleshoot a stamping die?

- Clean and lubricate the die components regularly.

- Inspect for wear and damage, and replace or repair components as needed.

- Adjust the die settings periodically to maintain optimal performance.

- Identify the problem, such as poor part quality, excessive wear, or press malfunctions.

- Analyze the root cause, such as misalignment, dull tooling, or material defects.

- Implement corrective actions, such as adjusting the die settings, replacing worn components, or improving the material quality.

Maintenance

Troubleshooting

8. Describe the different types of stamping presses used in tool and die making?

- Mechanical Presses: Powered by a flywheel and crankshaft mechanism.

- Hydraulic Presses: Powered by hydraulic fluid.

- Pneumatic Presses: Powered by compressed air.

- Servo Presses: Computer-controlled presses that offer precise control over the press cycle.

9. What are the safety precautions to be taken when working with tool and die equipment?

- Wear appropriate protective gear, such as safety glasses, gloves, and earplugs.

- Identify and avoid potential hazards, such as sharp edges, rotating machinery, and electrical hazards.

- Follow established safety procedures and lockout/tagout protocols.

- Be aware of the location of emergency stop buttons and other safety devices.

- Receive proper training and supervision before operating any tool and die equipment.

10. How do you stay updated on the latest trends and technologies in tool and die making?

- Attend industry conferences and workshops.

- Read trade magazines and technical publications.

- Participate in online forums and discussion groups.

- Consult with industry experts and vendors.

- Seek opportunities for professional development and training.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Repair.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Repair‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Repair professionals are the backbone of manufacturing. They ensure that the tools and dies used in mass production processes are in top condition to produce consistent, high-quality parts.

1. Preventative Maintenance

Conduct regular inspections and adjustments on tools and dies to prevent breakdowns and extend their lifespan.

- Identify potential problems and take corrective actions to minimize downtime.

- Lubricate and clean tools and dies according to manufacturer’s specifications.

2. Troubleshooting

Diagnose and resolve issues with tools and dies quickly and efficiently, ensuring minimal disruption to production.

- Analyze machine performance data and identify root causes of problems.

- Repair or replace defective components using precision measuring instruments.

3. Overhaul and Reconditioning

Perform major overhauls and reconditioning of tools and dies to restore them to optimal working condition.

- Disassemble tools and dies, clean and inspect components.

- Replace worn or damaged parts, resurface mating surfaces, and align components with precision.

4. Quality Control

Ensure that repaired or reconditioned tools and dies meet stringent quality standards before returning them to production.

- Inspect and test tools and dies using a variety of measuring instruments and techniques.

- Maintain accurate records of repairs and reconditioning activities.

Interview Tips

To ace an interview for a Tool and Die Repair position, it’s crucial to be prepared and demonstrate your technical skills, problem-solving abilities, and attention to detail.

1. Research the Company and Role

This shows the interviewer that you’re invested in the opportunity and that you’ve taken the time to understand the company’s industry and the specific requirements of the role.

- Visit the company’s website and social media pages to learn about their products, services, and culture.

- Thoroughly review the job description and identify the key responsibilities and skills required.

2. Highlight Your Experience and Skills

Emphasize your technical expertise in tool and die repair, including your ability to perform preventive maintenance, troubleshoot issues, and overhaul equipment.

- Quantify your accomplishments whenever possible. For example, instead of saying “I repaired tools and dies,” say “I repaired over 500 tools and dies, reducing downtime by 20%.”

- Use specific examples to demonstrate your skills. For example, describe a time when you diagnosed a complex problem with a tool and implemented a solution that prevented further breakdowns.

3. Demonstrate Your Problem-Solving Abilities

Tool and Die Repair often requires the ability to solve complex problems quickly and efficiently. Prepare for the interview by thinking about potential problems you may encounter on the job and how you would approach them.

- Describe a situation where you encountered a challenging problem and how you used your analytical skills to find a solution.

- Emphasize your ability to work independently and as part of a team to resolve issues.

4. Showcase Your Attention to Detail

Precision and attention to detail are essential in Tool and Die Repair. Highlight your experience in performing precise measurements, following technical specifications, and maintaining accurate records.

- Describe a time when you successfully completed a complex repair or overhaul, ensuring that the tool or die met or exceeded quality standards.

- Emphasize your commitment to safety and following established procedures.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool and Die Repair interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!