Are you gearing up for an interview for a Tool and Die Technician position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Tool and Die Technician and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

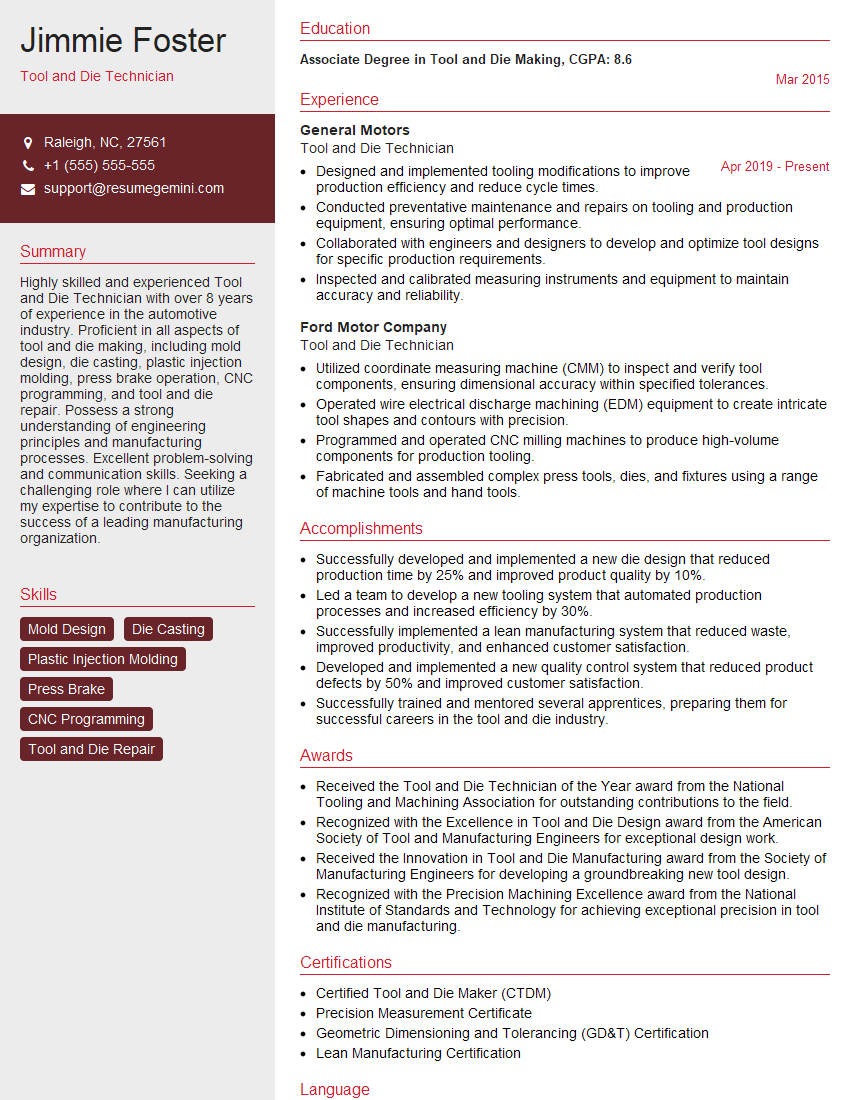

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool and Die Technician

1. Explain the process of designing a tool or die?

The process of designing a tool or die involves several steps:

- Understanding the customer’s requirements and specifications

- Developing a concept and creating a design using CAD software

- Selecting the appropriate materials and manufacturing processes

- Simulating the tool or die to ensure functionality and efficiency

- Prototyping and testing the tool or die

- Making modifications and refinements based on testing results

- Finalizing the design and preparing for production

2. What types of CAD software are you proficient in?

I am proficient in various CAD software, including:

- SolidWorks

- CATIA

- AutoCAD

- Siemens NX

- Creo Parametric

I have experience using these software for designing tools, dies, and other components.

- I am familiar with the features and capabilities of these software, and I am confident in my ability to use them to create high-quality designs.

3. How do you ensure the accuracy and precision of your designs?

To ensure the accuracy and precision of my designs, I follow several practices:

- I use precise measuring tools and equipment

- I perform thorough quality checks at each stage of the design process

- I collaborate with engineers and other technicians to review and validate my designs

- I stay updated with the latest industry standards and best practices

4. What are the different types of materials used in tool and die making?

The different types of materials used in tool and die making include:

- Tool steels

- High-speed steels

- Cemented carbides

- Ceramics

- Plastics

The choice of material depends on the specific application and requirements.

- I have experience working with a variety of materials and can advise on the best choice for a given application.

5. Describe the different types of manufacturing processes used in tool and die making?

The different types of manufacturing processes used in tool and die making include:

- CNC machining

- EDM (Electrical Discharge Machining)

- Grinding

- Heat treatment

- Coating

Each process has its own advantages and is used for different applications.

- I am familiar with the different manufacturing processes and can select the most appropriate one for a given task.

6. What are the key factors to consider when selecting a manufacturing process for a tool or die?

The key factors to consider when selecting a manufacturing process for a tool or die include:

- The geometry and complexity of the part

- The required accuracy and precision

- The material of the part

- The production volume

- The available resources and budget

By considering these factors, I can select the most appropriate manufacturing process for a given application.

7. What are the common problems that can occur during tool and die making?

Some common problems that can occur during tool and die making include:

- Design errors

- Material defects

- Manufacturing errors

- Improper heat treatment

- Wear and tear

It is important to anticipate and prevent these problems by following best practices and using quality control measures.

8. How do you troubleshoot and resolve problems that occur during tool and die making?

To troubleshoot and resolve problems that occur during tool and die making, I follow several steps:

- Identify the problem and its potential causes

- Inspect the tool or die to identify any defects or damage

- Review the design and manufacturing processes to identify any errors

- Consult with engineers and other technicians to gather additional insights

- Implement corrective actions to resolve the problem

- Test the tool or die to ensure the problem has been resolved

9. What are the latest trends and advancements in tool and die making?

The latest trends and advancements in tool and die making include:

- The use of additive manufacturing (3D printing) for rapid prototyping and production of complex geometries

- The development of new materials with improved properties and performance

- The integration of sensors and IoT devices for monitoring and control of tool and die processes

- The use of artificial intelligence (AI) for optimizing design and manufacturing processes

I am familiar with these trends and advancements and am excited to apply them in my work.

10. What are your strengths and weaknesses as a Tool and Die Technician?

My strengths as a Tool and Die Technician include:

- Strong technical skills and knowledge

- Experience in designing and manufacturing a variety of tools and dies

- Excellent problem-solving and troubleshooting abilities

- Attention to detail and precision

- Ability to work independently and as part of a team

My weakness is that I lack experience in some of the latest trends and advancements in tool and die making. However, I am eager to learn and develop in these areas.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool and Die Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool and Die Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool and Die Technicians play a crucial role in the manufacturing industry, helping to ensure that precision tools, dies, and molds meet exacting specifications. Their responsibilities encompass a wide range of tasks, including:

1. Design and Fabrication

Tool and Die Technicians work with engineers and designers to develop and create tools, dies, and molds used in stamping, forming, and cutting operations. They use their knowledge of materials, manufacturing processes, and quality control to ensure that the finished products meet the required specifications.

- Analyze blueprints, drawings, and specifications to determine the tools and equipment needed for production.

- Select and prepare materials, such as steel, aluminum, and plastics, for fabrication.

- Operate machine tools, such as lathes, milling machines, and grinders, to shape and finish tools and dies.

- Inspect and test tools and dies to ensure accuracy and quality.

2. Inspection and Maintenance

Tool and Die Technicians are responsible for inspecting and maintaining tools, dies, and molds to ensure they are in good working condition. They perform regular maintenance tasks, such as cleaning, lubricating, and adjusting, to prevent breakdowns and extend the lifespan of the equipment.

- Inspect tools and dies for wear, damage, or corrosion.

- Perform routine maintenance, such as cleaning, lubricating, and adjusting, to keep tools and dies in good working order.

- Identify and repair or replace worn or damaged parts.

3. Installation and Troubleshooting

Tool and Die Technicians assist with the installation and troubleshooting of tools and dies in production lines. They work with machine operators and maintenance personnel to ensure that the equipment is properly set up and functioning correctly.

- Install and align tools and dies in presses and other machines.

- Troubleshoot and resolve issues with tool and die performance.

- Provide technical support and training to operators and maintenance personnel.

4. Research and Development

Tool and Die Technicians stay abreast of the latest technologies and manufacturing processes. They conduct research and development activities to improve tool and die designs and processes. This can involve exploring new materials, experimenting with new techniques, and collaborating with engineers and researchers.

- Research new materials, processes, and techniques to improve tool and die performance.

- Conduct experiments and tests to evaluate new designs and processes.

- Collaborate with engineers and researchers to develop new and innovative solutions.

Interview Tips

Preparing for a Tool and Die Technician interview requires a combination of technical knowledge, industry experience, and effective communication skills. Here are some tips to help you ace your interview:

1. Research the Company and Industry

Before the interview, take the time to research the company and the specific industry they operate in. This will give you a better understanding of the company’s goals, values, and the challenges they face. By demonstrating your knowledge of the industry, you can show the interviewer that you are genuinely interested in the position and that you have a good grasp of the technical aspects of the job.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and articles to stay up-to-date on the latest trends and technologies.

- Attend industry events and conferences to network with professionals and learn about new developments.

2. Highlight Your Technical Skills

Tool and Die Technicians are highly skilled individuals with a strong foundation in mathematics, physics, and engineering principles. During the interview, emphasize your technical skills and knowledge by providing specific examples of your work. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions.

- Discuss your experience with different types of tools and dies, such as stamping dies, forming dies, and cutting dies.

- Highlight your proficiency in operating machine tools and your understanding of manufacturing processes.

- Share examples of how you have used your technical skills to solve problems and improve efficiency.

3. Showcase Your Industry Experience

Relevant industry experience is highly valued in Tool and Die Technician roles. If you have worked in a manufacturing environment, be sure to highlight your experience and the responsibilities you have held. Explain how your experience has prepared you for the specific role you are applying for and how you can contribute to the company’s success.

- Describe your previous roles and responsibilities as a Tool and Die Technician.

- Share examples of successful projects you have worked on and the outcomes you achieved.

- Explain how your industry experience has given you a deep understanding of manufacturing processes and best practices.

4. Communicate Effectively

Tool and Die Technicians often work as part of a team and need to be able to communicate effectively with colleagues, supervisors, and customers. During the interview, demonstrate your communication skills by being clear, concise, and professional in your responses. Actively listen to the interviewer’s questions and ask clarifying questions to show that you are engaged and interested in the position.

- Speak claramente y concisamente, evitando la jerga técnica o las siglas que el entrevistador pueda no entender.

- Haga preguntas aclaratorias para demostrar que está comprometido y que desea comprender completamente la posición.

- Muestre su capacidad para trabajar en equipo y colaborar con otros compartiendo ejemplos de proyectos exitosos en los que ha participado.

5. Prepare Questions to Ask

Asking thoughtful questions at the end of the interview is a great way to show your interest in the position and to learn more about the company and the role. Prepare a few questions in advance that are specific to the job and the company. This demonstrates that you have done your research and that you are genuinely interested in the opportunity.

- Ask about the company’s strategic goals and how the Tool and Die Technician role contributes to those goals.

- Inquire about the company’s commitment to training and development for its employees.

- Ask about the company’s culture and values and how they align with your own.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool and Die Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool and Die Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.