Feeling lost in a sea of interview questions? Landed that dream interview for Tool Design Drafter but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Tool Design Drafter interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

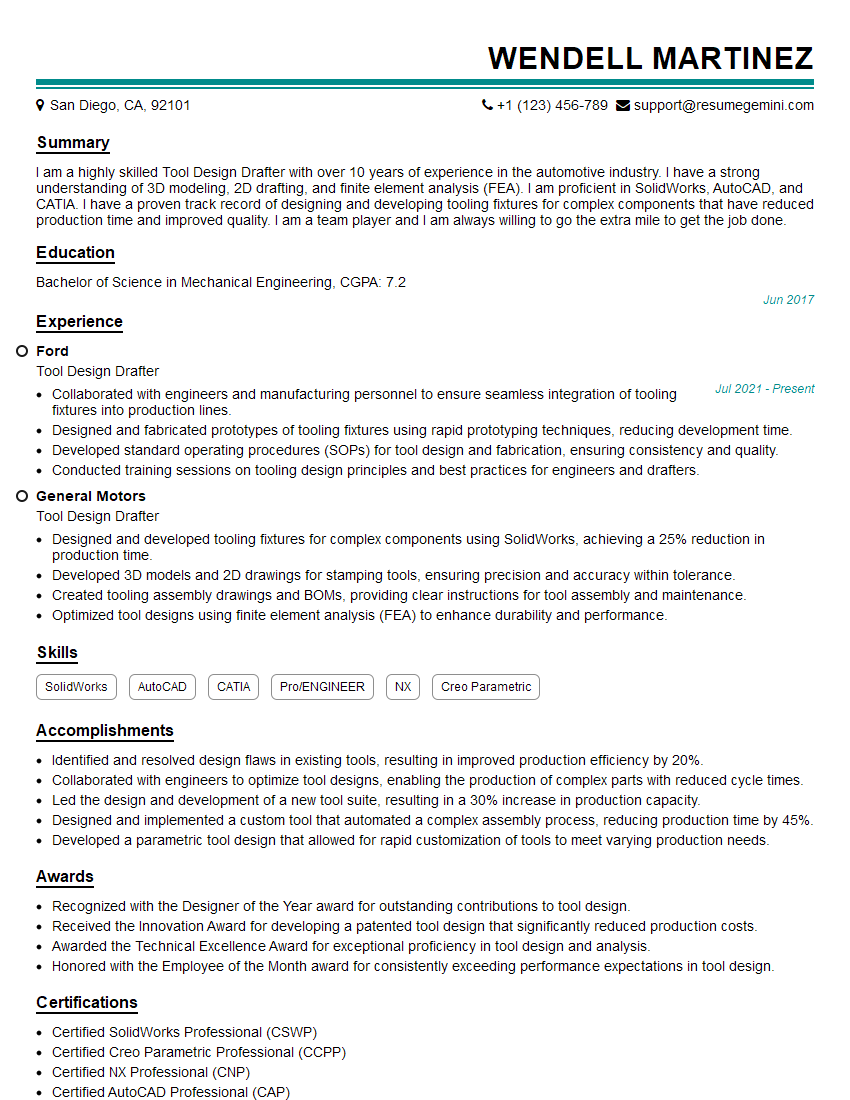

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Design Drafter

1. How do you approach the design of a new tool?

In designing a new tool, I would begin by gathering all relevant information, including product specifications, production requirements, and material properties. I would then create a preliminary design based on this information. Once the preliminary design is complete, I would perform a detailed analysis to ensure that it meets all the necessary specifications.

2. Can you describe the process of creating a 3D model of a tool?

Creating the geometry

- Start by sketching the basic shape of the tool.

- Use 3D modeling software to create a more detailed model.

Adding details

- Add features such as holes, slots, and threads.

- Create assemblies of multiple parts.

3. What are the different types of materials used in tool design?

The most common types of materials used in tool design are steel, aluminum, and plastic. Steel is a strong and durable material that is well-suited for cutting tools. Aluminum is a lightweight and corrosion-resistant material that is often used for molds and fixtures. Plastic is a versatile material that can be used for a variety of applications, including handles and grips.

4. What are the different surface finishes used in tool design?

The most common surface finishes used in tool design are polishing, grinding, and plating. Polishing is used to create a smooth and shiny surface. Grinding is used to create a rougher surface that can provide better grip. Plating is used to protect the surface of the tool from corrosion and wear.

5. What are the different types of tolerances used in tool design?

The most common types of tolerances used in tool design are linear tolerances, angular tolerances, and geometric tolerances. Linear tolerances specify the allowable variation in the length or width of a feature. Angular tolerances specify the allowable variation in the angle of a feature. Geometric tolerances specify the allowable variation in the shape of a feature.

6. What are the different types of fits used in tool design?

The most common types of fits used in tool design are clearance fits, interference fits, and transition fits. Clearance fits allow for some movement between the two mating parts. Interference fits create a tight fit between the two mating parts. Transition fits fall somewhere in between clearance fits and interference fits.

7. What are the different types of fasteners used in tool design?

The most common types of fasteners used in tool design are screws, bolts, nuts, and washers. Screws are used to hold two or more pieces of material together. Bolts are similar to screws, but they have a head that is larger than the shaft. Nuts are used to secure bolts. Washers are used to distribute the load of a fastener and to prevent damage to the material being fastened.

8. What are the different types of springs used in tool design?

The most common types of springs used in tool design are compression springs, extension springs, and torsion springs. Compression springs are used to store energy when they are compressed. Extension springs are used to store energy when they are stretched. Torsion springs are used to store energy when they are twisted.

9. What are the different types of bearings used in tool design?

The most common types of bearings used in tool design are ball bearings, roller bearings, and plain bearings. Ball bearings use balls to reduce friction between two surfaces. Roller bearings use rollers to reduce friction between two surfaces. Plain bearings use a sliding contact between two surfaces.

10. What are the different types of seals used in tool design?

The most common types of seals used in tool design are O-rings, gaskets, and packing. O-rings are used to seal fluid or gas leaks. Gaskets are used to seal flanges or other mating surfaces. Packing is used to seal gaps between moving parts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Design Drafter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Design Drafter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Design Drafters create technical drawings and documentation for the design and manufacture of tools, machinery, and other industrial equipment.

1. Design Analysis and Development

Analyze engineering specifications and sketches to create detailed design drawings.

- Develop and modify design concepts to meet specific requirements.

- Collaborate with engineers and other design professionals to refine designs.

2. Drafting and Documentation

Produce technical drawings using computer-aided design (CAD) software.

- Create assembly drawings, part drawings, and other technical documentation.

- Ensure accuracy and completeness of drawings according to industry standards.

3. Material and Process Selection

Select appropriate materials and manufacturing processes for tool components.

- Consider factors such as strength, durability, and cost.

- Recommend modifications to designs based on material and manufacturing constraints.

4. Quality Control and Testing

Monitor and inspect tool designs for compliance with specifications.

- Conduct tolerance analysis and stress tests to ensure proper functioning.

- Identify and correct errors in designs before manufacturing.

Interview Tips

To ace the interview for a Tool Design Drafter position, candidates should prepare thoroughly and showcase their skills and qualifications.

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and values.

- Research the specific job requirements and responsibilities.

- Identify areas where your skills and experience align with the position.

2. Highlight CAD Proficiency

Demonstrate your expertise in CAD software, including the specific software used by the company.

- Provide examples of your work that showcase your ability to create detailed and accurate drawings.

- Be prepared to discuss your knowledge of drafting standards and conventions.

3. Emphasize Analytical and Detail-Oriented Skills

Explain how your analytical and problem-solving abilities contribute to your success as a Tool Design Drafter.

- Describe how you analyze design specifications and identify potential issues.

- Share examples of how your attention to detail has prevented errors in designs.

4. Showcase Collaboration and Communication Skills

Highlight your ability to work effectively with engineers, designers, and manufacturers.

- Explain how you communicate technical information clearly and concisely.

- Provide examples of how you have collaborated with others to develop and refine designs.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Design Drafter role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.