Are you gearing up for a career in Tool/Die Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tool/Die Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

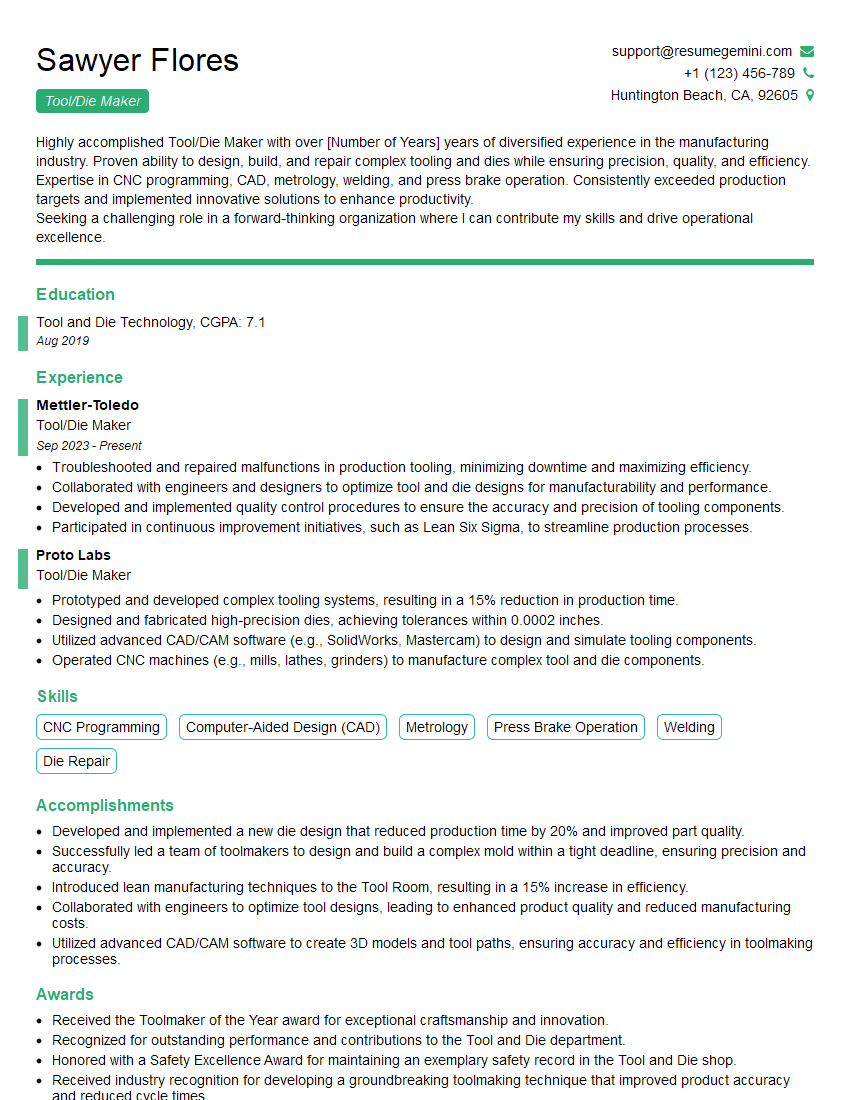

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool/Die Maker

1. Describe the process of creating a tool or die from start to finish?

The process of creating a tool or die from start to finish typically involves the following steps:

- Design the tool or die using CAD software.

- Create a prototype of the tool or die using rapid prototyping or 3D printing.

- Machine the tool or die using CNC machining or EDM.

- Heat treat the tool or die to improve its durability and performance.

- Grind and polish the tool or die to achieve the desired finish.

- Test the tool or die to ensure that it meets the required specifications.

2. What are the different types of materials used in tool and die making?

Metals

- Steel

- Aluminum

- Copper

- Brass

Plastics

- ABS

- PC

- PEEK

- Nylon

Ceramics

- Zirconia

- Alumina

- Carbide

- Nitride

3. What are the different types of tool and die making machines?

The different types of tool and die making machines include:

- CNC machining centers

- EDM machines

- Grinders

- Polishers

- Heat treatment ovens

4. What are the different types of tool and die making processes?

The different types of tool and die making processes include:

- Milling

- Turning

- Drilling

- Grinding

- EDM

- Heat treatment

5. What are the different types of tool and die making industries?

The different types of tool and die making industries include:

- Automotive

- Aerospace

- Medical

- Electronics

- Consumer products

6. What are the challenges of tool and die making?

The challenges of tool and die making include:

- Precision

- Complexity

- Materials

- Time

- Cost

7. What are the rewards of tool and die making?

The rewards of tool and die making include:

- Job satisfaction

- High wages

- Career advancement opportunities

- Making a difference in the world

8. What are your strengths as a tool and die maker?

My strengths as a tool and die maker include:

- Precision

- Attention to detail

- Problem-solving skills

- Teamwork skills

- Communication skills

9. What are your weaknesses as a tool and die maker?

My weaknesses as a tool and die maker include:

- I can be impatient at times.

- I am not always the best at delegating tasks.

- I can be a bit of a perfectionist.

10. What are your career goals as a tool and die maker?

My career goals as a tool and die maker are to:

- Become a master tool and die maker.

- Start my own tool and die making business.

- Teach tool and die making at a technical school.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool/Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool/Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool/Die Makers play a vital role in manufacturing industry. They are responsible for creating and maintaining the tools and dies used to produce a wide variety of products, from automotive parts to medical devices. Their key responsibilities include:Designing and Fabricating Tools and Dies:

1. Designing Tools and Dies

Tool/Die Makers work closely with engineers to design and create the tools and dies needed for production. They use a variety of computer-aided design (CAD) software to develop detailed drawings of the tools and dies. They must have a strong understanding of engineering principles and the properties of different materials.

2. Fabricating Tools and Dies

Once the tools and dies have been designed, Tool/Die Makers fabricate them using a variety of machining and metalworking techniques. They use precision measuring tools and equipment to ensure that the tools and dies meet the required specifications.

3. Assembling and Installing Tools and Dies

Tool/Die Makers assemble and install the tools and dies into production machinery. They must ensure that the tools and dies are properly aligned and calibrated. They may also be responsible for training operators on how to use the tools and dies safely and efficiently.

4. Maintaining and Repairing Tools and Dies

Tool/Die Makers are responsible for maintaining and repairing the tools and dies they create. They must regularly inspect the tools and dies for wear and tear. They may also be required to make repairs or adjustments to the tools and dies as needed.

5. Quality Control

Tool/Die Makers are responsible for ensuring that the tools and dies they create meet the required quality standards. They use a variety of inspection techniques to check the accuracy and precision of the tools and dies. They may also be responsible for developing and implementing quality control procedures.

Interview Preparation Tips

Preparing for a Tool/Die Maker interview can be daunting because you want to ace the interview. Here are some tips to help you stand out from the competition:

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on its website, social media pages, and industry publications. You can also find information about the job by reading the job description and talking to your recruiter.

2. Practice Your Answers

Once you have a good understanding of the company and the position, it is time to practice your answers to common interview questions. This will help you feel confident and prepared during the interview. Some common interview questions for Tool/Die Makers include:

- Tell me about your experience in designing and fabricating tools and dies.

- What are some of the challenges you have faced in your work as a Tool/Die Maker?

- How do you stay up-to-date on the latest technologies and trends in the industry?

- What is your quality control process?

- Why are you interested in working for our company?

3. Bring a Portfolio

If you have a portfolio of your work, bring it to the interview. This will give the interviewer a chance to see your skills and experience firsthand. Your portfolio should include examples of your work in different areas, such as:

- Designing and fabricating tools and dies

- Assembling and installing tools and dies

- Maintaining and repairing tools and dies

- Quality control

4. Dress Professionally

First impressions are important, so dress professionally for the interview. This means wearing a suit or business casual attire. You should also make sure your clothes are clean and pressed.

5. Be Enthusiastic and Positive

The interviewer wants to see that you are enthusiastic about the job and that you are a positive person. Be sure to smile and make eye contact during the interview. You should also be prepared to talk about your accomplishments and how you can contribute to the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Tool/Die Maker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.