Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Tool Grinder Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

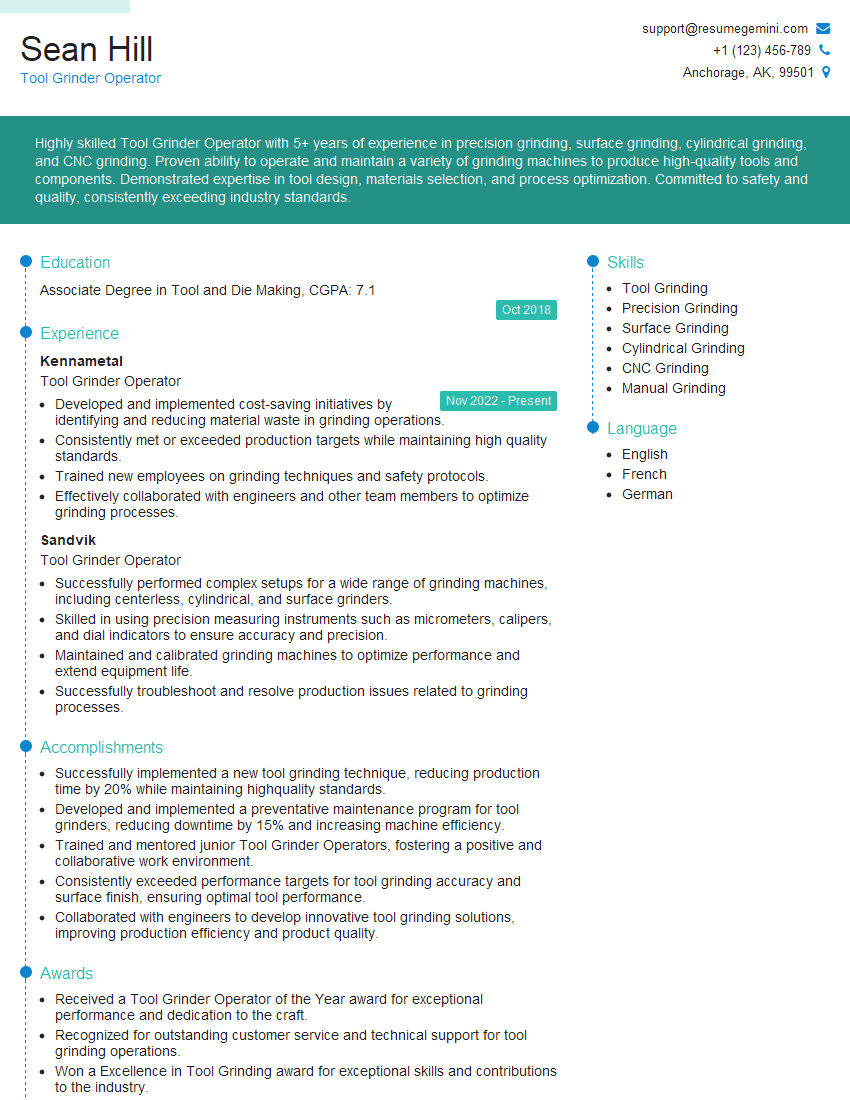

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Grinder Operator

1. What are the different types of grinding machines used in tool grinding?

There are various types of grinding machines used in the tool grinding process, each designed for specific applications. Here are the common types:

- Surface Grinders: Used for grinding flat surfaces of tools, such as inserts, cutting tools, and dies.

- Cylindrical Grinders: Designed to grind cylindrical surfaces, such as shafts, pins, and rollers.

- Centerless Grinders: Used for grinding cylindrical workpieces without the need for centers, allowing for continuous feeding of workpieces.

- Internal Grinders: Intended for grinding the internal surfaces of tools, such as holes, bores, and cavities.

- Tool and Cutter Grinders: Specifically designed for grinding cutting tools, such as end mills, drill bits, and milling cutters, providing precise shaping and sharpening.

2. Explain the process of selecting the correct grinding wheel for a specific tool grinding application.

Factors to Consider:

- Material of the tool being ground

- Desired surface finish

- Grinding operation (e.g., roughing, finishing)

- Coolant type

Steps:

- Identify the material of the tool (e.g., steel, carbide, ceramic).

- Determine the required surface finish (e.g., rough, semi-finish, finish).

- Select the appropriate bond type (e.g., vitrified, resin, metal).

- Choose the correct grit size (e.g., coarse, medium, fine).

- Consider the coolant type (e.g., water-based, oil-based).

3. What are the safety precautions that must be observed when operating a tool grinding machine?

- Wear appropriate safety gear, including safety glasses, gloves, and earplugs.

- Ensure the machine is properly grounded and electrically safe.

- Inspect the grinding wheel for damage or cracks before use.

- Use proper workholding devices to secure the workpiece firmly.

- Maintain a safe distance from the grinding wheel and use guards or shields.

- Never attempt to adjust or repair the machine while it is running.

- Keep the work area clean and free of debris.

- Follow all established safety protocols and procedures.

4. How do you measure and inspect the accuracy of ground tools?

- Use precision measuring instruments, such as micrometers, calipers, and gauges.

- Check dimensions, tolerances, and surface finish.

- Inspect for any defects, such as burrs, cracks, or uneven surfaces.

- Compare the results to the specified requirements or drawings.

- Make necessary adjustments to the grinding process or machine settings if needed.

5. What is the importance of coolant in tool grinding?

- Cools the workpiece and grinding wheel, preventing overheating and damage.

- Lubricates the grinding wheel, reducing friction and wear.

- Washes away grinding debris, improving surface finish and preventing clogging.

- Helps to control the temperature of the workpiece, reducing distortion and ensuring dimensional accuracy.

- Can contain additives to enhance grinding performance, such as rust inhibitors or abrasives.

6. How do you troubleshoot common problems encountered during tool grinding?

- Excessive vibration: Check wheel balance, workpiece securement, and machine alignment.

- Poor surface finish: Adjust grinding wheel grit size, speed, or feed rate.

- Burning of the workpiece: Reduce grinding pressure, increase coolant flow, or use a different wheel.

- Wheel glazing: Use a dressing tool to remove the glazed layer from the wheel.

- Wheel breakage: Inspect the wheel for damage, ensure proper mounting, and check machine settings.

7. Describe the maintenance procedures required for tool grinding machines.

- Regular cleaning and lubrication of moving parts.

- Inspection and replacement of worn or damaged components, such as belts, bearings, and filters.

- Balancing of grinding wheels to ensure smooth operation.

- Checking and adjusting coolant systems for proper flow and concentration.

- Monitoring machine alignments and vibration levels.

- Following manufacturer’s recommended maintenance schedules.

8. How do you stay updated with the latest advancements in tool grinding technology?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Seek training and certification opportunities from equipment manufacturers.

- Network with other professionals in the field.

9. Can you explain the concept of surface grinding and its applications?

- Surface grinding involves using a rotating grinding wheel to remove material from the surface of a workpiece.

- Applications include flattening, smoothing, and creating precise surface finishes.

- Used in various industries, such as automotive, aerospace, and mold making.

- Can be performed using different grinding wheel types and techniques to achieve specific results.

10. Describe the role of coolants in cylindrical grinding operations.

- Coolants play a crucial role in cylindrical grinding by:

- Reducing friction and heat buildup, preventing workpiece damage and wheel glazing.

- Flushing away grinding debris, improving surface finish and wheel life.

- Lubricating the wheel and workpiece, minimizing wear and tear.

- Enhancing dimensional accuracy by controlling workpiece temperature.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Grinder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Grinder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Grinder Operators are highly skilled machinists responsible for maintaining and sharpening cutting tools and other metalworking equipment. They work in industrial settings, such as machine shops, manufacturing plants, and automotive repair facilities. Their primary responsibilities include:

1. Grinding and Sharpening Tools

Tool Grinder Operators use a variety of grinding machines to sharpen and reshape cutting tools, such as drills, milling cutters, and lathe tools. They ensure that tools are properly aligned and balanced to meet precise specifications.

2. Inspecting and Measuring Tools

Before and after grinding, Tool Grinder Operators carefully inspect and measure tools to ensure they meet quality standards. They use precision measuring equipment, such as micrometers and calipers, to verify dimensions and tolerances.

3. Adjusting and Maintaining Equipment

Tool Grinder Operators are responsible for maintaining and adjusting grinding machines to ensure optimal performance. They perform routine maintenance, such as lubrication, cleaning, and calibrating equipment, to prevent breakdowns and ensure accuracy.

4. Troubleshooting and Repairing Tools

When tools encounter issues, Tool Grinder Operators troubleshoot problems and make necessary repairs. They identify potential causes of defects and implement solutions to restore proper functionality.

Interview Tips

To ace an interview for a Tool Grinder Operator position, it’s essential to prepare effectively and present your skills and experience in the best possible light. Here are some key tips:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific Tool Grinder Operator position. This will help you understand their operations, culture, and the responsibilities associated with the role.

2. Highlight Your Technical Skills

Emphasize your proficiency in using grinding machines, precision measuring equipment, and other relevant tools. Provide specific examples of how you have used these skills to achieve positive outcomes.

3. Showcase Your Attention to Detail

Tool Grinder Operators must be meticulous and detail-oriented. Highlight your ability to inspect and measure tools with precision and identify potential problems before they escalate.

4. Demonstrate Your Problem-Solving Abilities

Interviewers will be interested in your ability to troubleshoot and resolve issues promptly. Provide examples of situations where you have identified and resolved problems related to grinding and sharpening tools.

5. Prepare for Technical Questions

Expect to be asked technical questions about grinding techniques, equipment maintenance, and tool inspection procedures. Practice answering these questions concisely and accurately.

6. Be Prepared to Discuss Safety

Safety is paramount in industrial settings. Demonstrate your understanding of workplace safety protocols and your commitment to maintaining a safe work environment.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Tool Grinder Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.