Are you gearing up for a career in Tool Grinding Technician? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Tool Grinding Technician and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

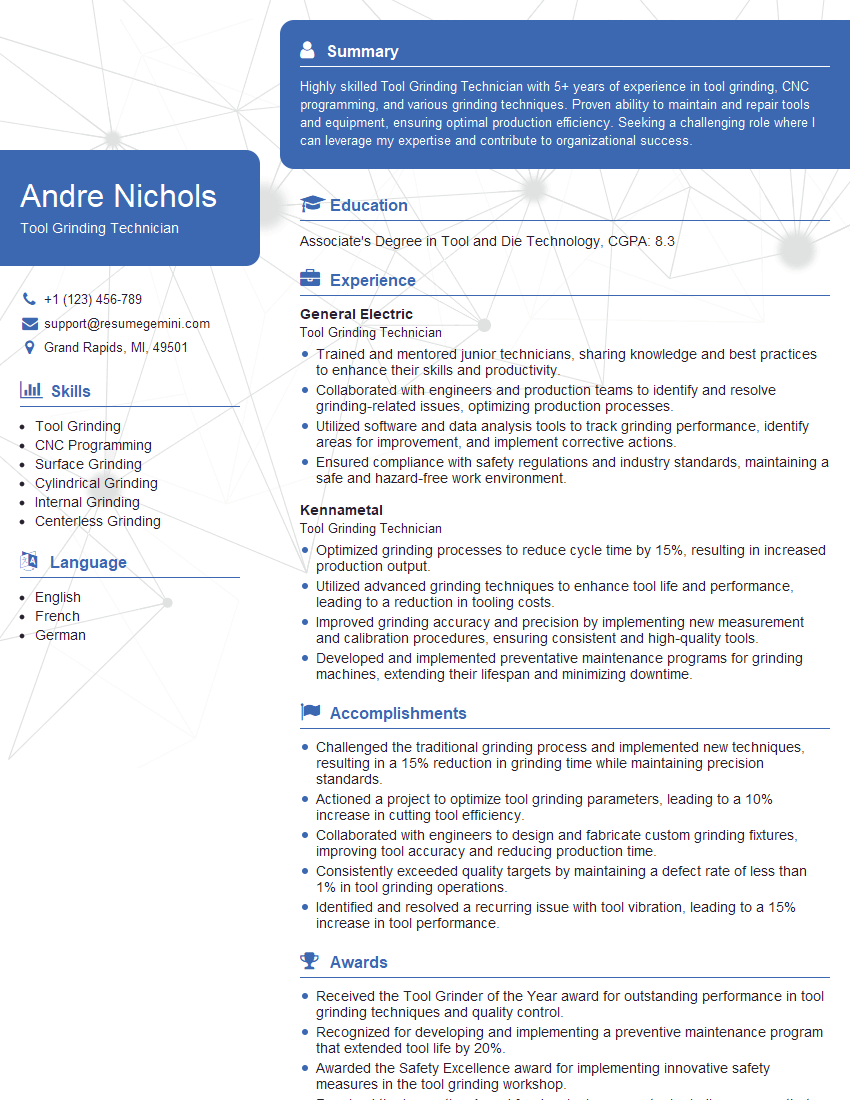

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Tool Grinding Technician

1. What are the different types of grinding machines and their uses?

There are various types of grinding machines used for different purposes in the manufacturing industry:

- Cylindrical grinders: Used to grind cylindrical surfaces of shafts, pins, and similar parts.

- Surface grinders: Suitable for grinding flat surfaces on parts, such as hardened steel, ceramics, and glass.

- Internal grinders: Designed to grind bores, holes, and internal surfaces of cylindrical and non-cylindrical parts.

- Centerless grinders: Used to grind workpieces without the need for centers, making them suitable for high-volume production.

2. Describe the process of grinding a tool using a grinding machine.

- Mounting the workpiece: Securely fasten the tool in the appropriate fixture or chuck of the grinding machine.

- Selecting the grinding wheel: Choose the correct grinding wheel based on the material of the tool and desired finish.

- Setting the grinding parameters: Determine the speed, feed rate, and depth of cut based on the tool material and grinding wheel characteristics.

- Dressing the grinding wheel: Prepare the grinding wheel by removing any glazing or buildup to ensure a sharp and effective cutting edge.

- Grinding the tool: Move the tool against the rotating grinding wheel to remove material and shape the tool.

- Inspecting the finished tool: Check the accuracy, surface finish, and sharpness of the ground tool using appropriate measuring instruments.

3. What are the different types of grinding wheels and their applications?

Grinding wheels come in various types, each suited for specific materials and applications:

- Aluminum oxide wheels: General-purpose wheels used for grinding steel, cast iron, and non-ferrous metals.

- Silicon carbide wheels: Suitable for grinding hard materials such as ceramics, glass, and masonry.

- Cubic boron nitride (CBN) wheels: Designed for high-speed grinding of hardened steels and superalloys.

- Diamond wheels: Used for grinding extremely hard materials like diamond, carbide, and ceramics.

4. How do you ensure the accuracy and precision of ground tools?

Achieving accuracy and precision in grinding tools involves the following steps:

- Proper machine setup: Ensure the grinding machine is calibrated and operating within specified tolerances.

- Precision measuring instruments: Use accurate tools like micrometers, calipers, and gauges to measure and verify dimensions.

- Skilled operators: Experienced operators with a thorough understanding of grinding principles and techniques can consistently produce high-quality tools.

- Quality control: Implement a rigorous quality control process to inspect and verify the accuracy and precision of ground tools.

5. What are the common problems encountered in tool grinding and how do you troubleshoot them?

Troubleshooting common problems in tool grinding requires a systematic approach:

- Excessive wheel wear: Check the wheel condition, dressing frequency, and grinding parameters.

- Poor surface finish: Adjust the grinding wheel specifications, feed rate, and coolant application.

- Chattering or vibration: Balance the grinding wheel, check for loose machine components, and adjust the grinding parameters.

- Tool overheating: Ensure proper coolant flow, adjust the grinding parameters, and use the appropriate wheel type.

6. How do you maintain and calibrate a grinding machine for optimal performance?

Regular maintenance and calibration are essential for maintaining the optimal performance of a grinding machine:

- Lubrication: Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants.

- Wheel balancing: Ensure the grinding wheel is balanced to minimize vibration and improve surface finish.

- Coolant system: Inspect and clean the coolant system regularly to ensure proper flow and cooling.

- Calibration: Use precision measuring instruments to calibrate the machine’s axes, spindle speed, and other critical parameters.

7. What are the safety precautions to consider when operating a grinding machine?

Safety is paramount when operating a grinding machine:

- Wear proper personal protective equipment (PPE): Safety glasses, gloves, and earplugs are essential.

- Secure the workpiece: Ensure the workpiece is securely fastened to prevent it from flying out.

- Never operate a machine with a damaged or cracked grinding wheel: Defective wheels can shatter, causing serious injuries.

- Keep the work area clean: Remove any grinding dust or debris that could pose a tripping hazard.

8. What are the latest advancements in tool grinding technology?

The tool grinding industry is constantly evolving with technological advancements:

- Computer Numerical Control (CNC) grinding machines: Provide precise and efficient grinding operations with automated control.

- Advanced grinding wheels: New materials and bonding techniques enhance grinding efficiency and tool life.

- Laser-assisted grinding: Enables high-precision grinding with minimal heat-affected zones.

- Artificial intelligence (AI): AI algorithms are used to optimize grinding parameters and improve machine performance.

9. How do you stay updated with the latest techniques and best practices in tool grinding?

Continuous learning is vital for staying up-to-date in the field:

- Attend industry conferences and workshops: Learn from experts and network with fellow professionals.

- Read technical publications and journals: Stay informed about new technologies and advancements.

- Engage in online forums and discussion groups: Connect with other practitioners and share knowledge.

- Seek opportunities for training and certification: Invest in professional development to enhance your skills.

10. What are your career aspirations as a tool grinding technician?

My career aspirations as a tool grinding technician are to:

- Master the latest techniques and technologies: Continuously improve my skills and knowledge to stay at the forefront of the industry.

- Contribute to innovative grinding solutions: Participate in projects that push the boundaries of tool grinding and advance manufacturing capabilities.

- Become a mentor and leader: Share my expertise and train future generations of tool grinding technicians.

- Promote the profession: Advocate for the importance of skilled trades and inspire young people to pursue careers in tool grinding.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Tool Grinding Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Tool Grinding Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Tool Grinding Technicians are responsible for sharpening and maintaining cutting tools used in various industries. They work with specialized machinery to ensure that tools meet precise specifications. Their key job responsibilities include:

1. Sharpening and Grinding Tools

Tool Grinding Technicians use grinding machines to sharpen and regrind cutting tools such as drills, milling cutters, and taps. They must have a deep understanding of the different types of tools and the appropriate grinding techniques to achieve the desired edge geometry.

- Select and install the correct grinding wheels based on the tool material and desired finish.

- Adjust machine settings, such as speed, feed, and coolant flow, to optimize grinding performance.

- Inspect and measure tools to ensure they meet specifications and tolerances.

2. Maintaining and Calibrating Equipment

Tool Grinding Technicians are responsible for maintaining and calibrating the grinding machines they use. This includes regular cleaning, lubrication, and adjustments to ensure optimal performance and accuracy.

- Perform routine maintenance tasks, such as cleaning, lubrication, and replacing worn parts.

- Calibrate grinding machines using precision instruments to ensure accuracy and repeatability.

- Monitor and troubleshoot equipment problems to minimize downtime and maintain productivity.

3. Understanding Tool Materials and Applications

Tool Grinding Technicians must have a thorough understanding of the different types of tool materials and their applications. They need to know how different materials react to grinding and how to achieve the desired cutting performance.

- Identify and select the appropriate tool materials based on the specific cutting application.

- Understand the heat treatment and surface coating processes used to enhance tool performance.

- Research and stay updated on the latest tool grinding techniques and technologies.

4. Quality Control and Inspection

Tool Grinding Technicians play a crucial role in quality control by ensuring that tools meet the required specifications. They inspect tools using precision measuring instruments and make adjustments as needed.

- Perform visual and dimensional inspections of tools to identify defects or non-conformances.

- Use specialized measuring equipment, such as micrometers, calipers, and surface roughness testers, to verify accuracy.

- Maintain records of inspection results and report any deviations from specifications.

Interview Tips

Preparation is key to acing the interview for the Tool Grinding Technician position. Here are some tips to help you stand out:

1. Research the Company and Role

Research the company’s history, products, and values. This will give you a better understanding of their business and what they are looking for in a Tool Grinding Technician. Also, carefully review the job description and identify the key skills and responsibilities.

- Visit the company website and social media pages.

- Read industry news and articles to gain insights into the company’s market position.

- Highlight in your resume and cover letter how your skills and experience align with the job requirements.

2. Practice Your Answers

Prepare for common interview questions by practicing your answers. This will help you feel more confident and articulate your thoughts clearly. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your work.

- Anticipate questions about your technical skills, experience with different types of grinding machines, and understanding of tool materials.

- Prepare examples of your problem-solving abilities and how you have resolved complex grinding issues.

- Be ready to discuss your quality control procedures and how you ensure accuracy and precision in your work.

3. Showcase Your Passion for the Field

Hiring managers are looking for candidates who are passionate about their work. Convey your enthusiasm for tool grinding and explain why you are interested in the role at their company. Highlight your commitment to continuous learning and your desire to stay updated on the latest industry trends and technologies.

- Share your knowledge of recent advancements in tool grinding techniques or equipment.

- Mention any certifications or training programs you have completed to enhance your skills.

- Express your interest in contributing to the company’s success through your expertise in tool grinding.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement. Prepare a few questions that show you are curious about the company’s operations, the team you would be working with, or the opportunities for professional development.

- Inquire about the company’s quality control standards and how you can contribute to maintaining them.

- Ask about opportunities for training and advancement within the organization.

- Show interest in the company’s investment in new technologies and how they impact the role of a Tool Grinding Technician.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Tool Grinding Technician, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Tool Grinding Technician positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.